A flexible joint angle sensor

An angle sensor, flexible joint technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of complex system, large detection error, limited application environment, etc., and achieve the effects of high measurement accuracy, simple and compact structure, and wide application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

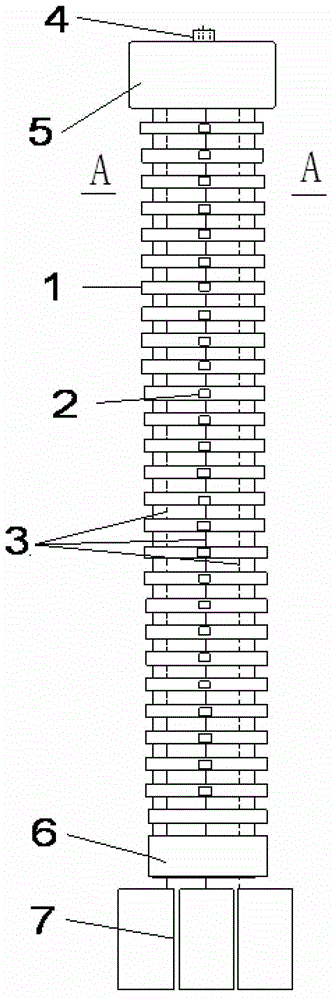

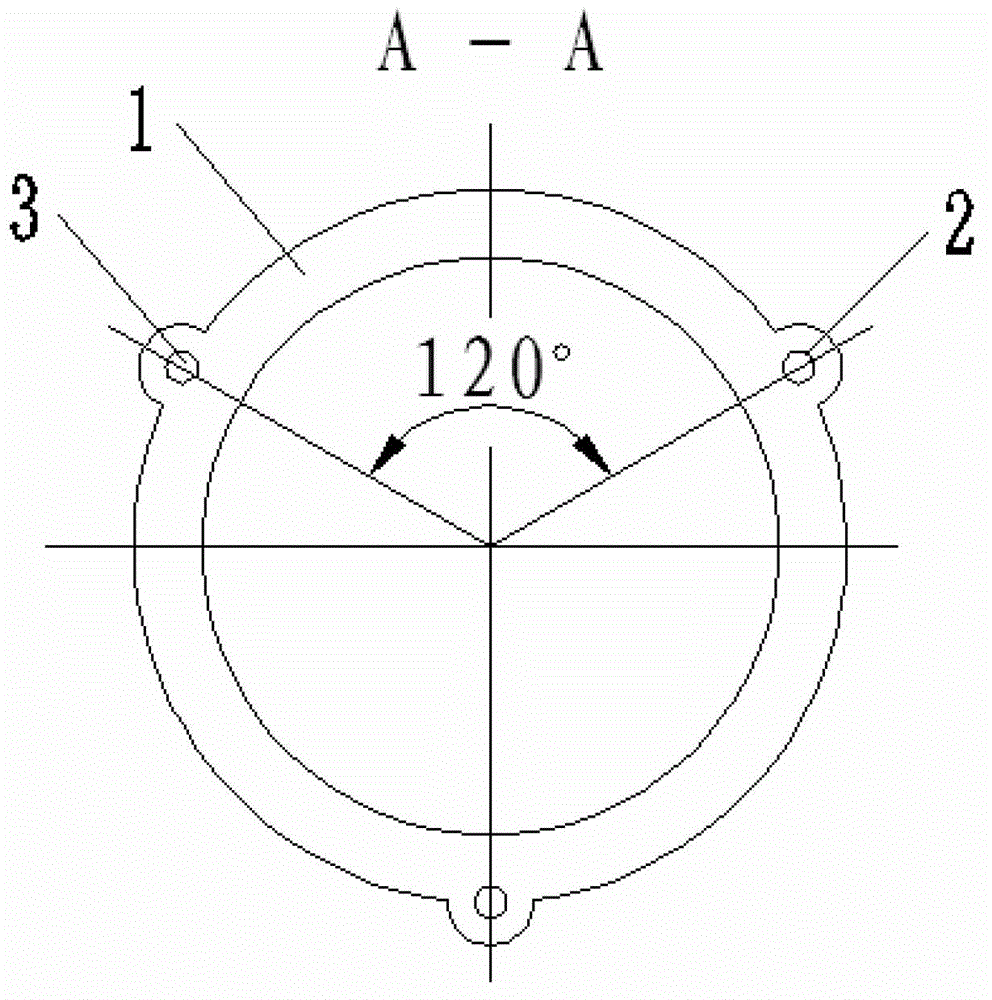

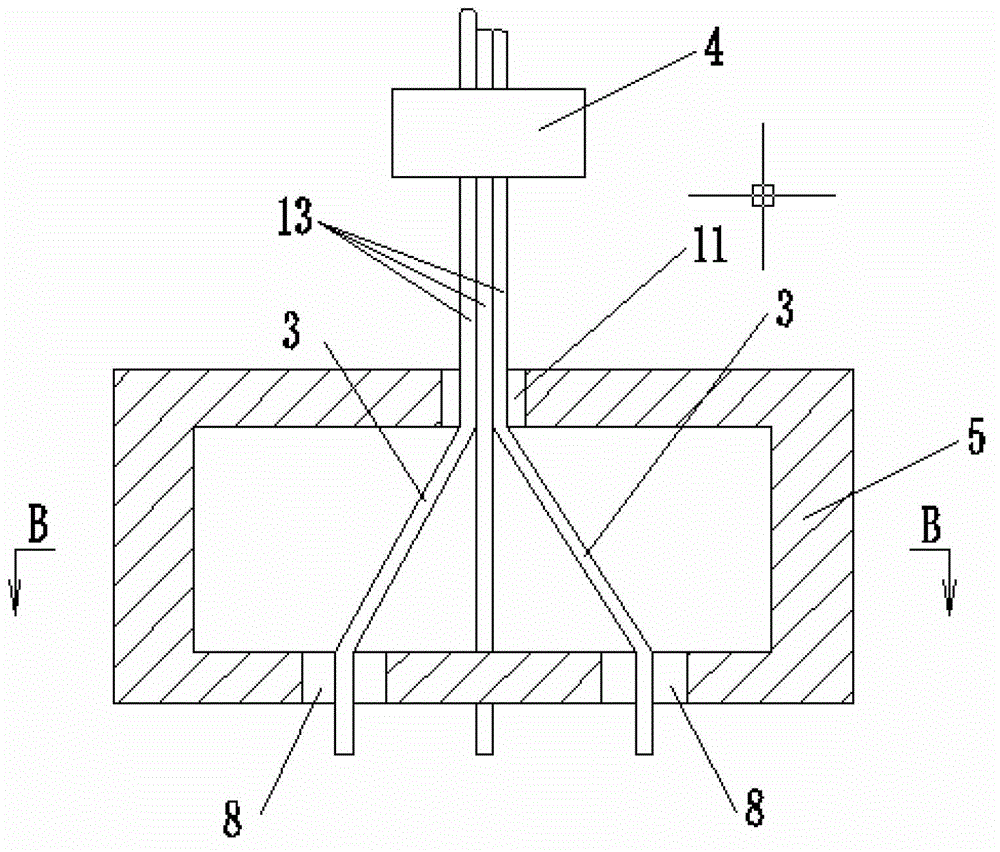

[0008] Embodiment 1: Combining Figure 1 to Figure 6 Illustrating this embodiment, this embodiment includes a flexible bellows 1, an upper fixing block 4, a fixing ring 5, a lower fixing block 6, a displacement sensor 7, three steel wires 3 and three steel wire sliding tracks. The upper end of the flexible bellows 1 is connected to the The fixing ring 5 is connected, the lower end of the flexible bellows 1 is connected with the lower fixing block 6, and each wave crest on the outer surface of the flexible bellows 1 is evenly distributed with three steel wire sliding tracks 2 along the circumference. The steel wire sliding track 2 on the wave crest is set up and down one by one, the fixing ring 5 is a hollow structure, a central hole 11 is arranged at the center of the upper end face of the fixing ring 5, and three upper through holes 8 are arranged on the lower end face of the fixing ring 5 , the lower fixing block 6 is provided with three lower through holes 9, the steel wire...

specific Embodiment approach 2

[0009] Specific implementation mode 2: Combining figure 2 Illustrating this embodiment, the three upper through holes 8 on the fixing ring 5 of this embodiment are evenly distributed along the circumference. This is designed so that the three steel wires 3 are uniformly stressed. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation three: combination image 3 , Figure 4 , Figure 5 , Image 6 Describing this embodiment, the three lower through holes 9 and the three upper through holes 8 in this embodiment are disposed in a one-to-one manner. This design is convenient for the steel wires 3 to pass through, so that the three steel wires 3 are evenly stressed. Other compositions and connection relationships are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com