Wafer Acceptance Test Method

A test method and wafer technology, applied in the direction of semiconductor/solid-state device testing/measurement, can solve problems such as unfavorable detection efficiency, inaccurate electrical parameter values, and inability to feed back electrical parameter values, so as to improve detection efficiency and save Effects of Time and Labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

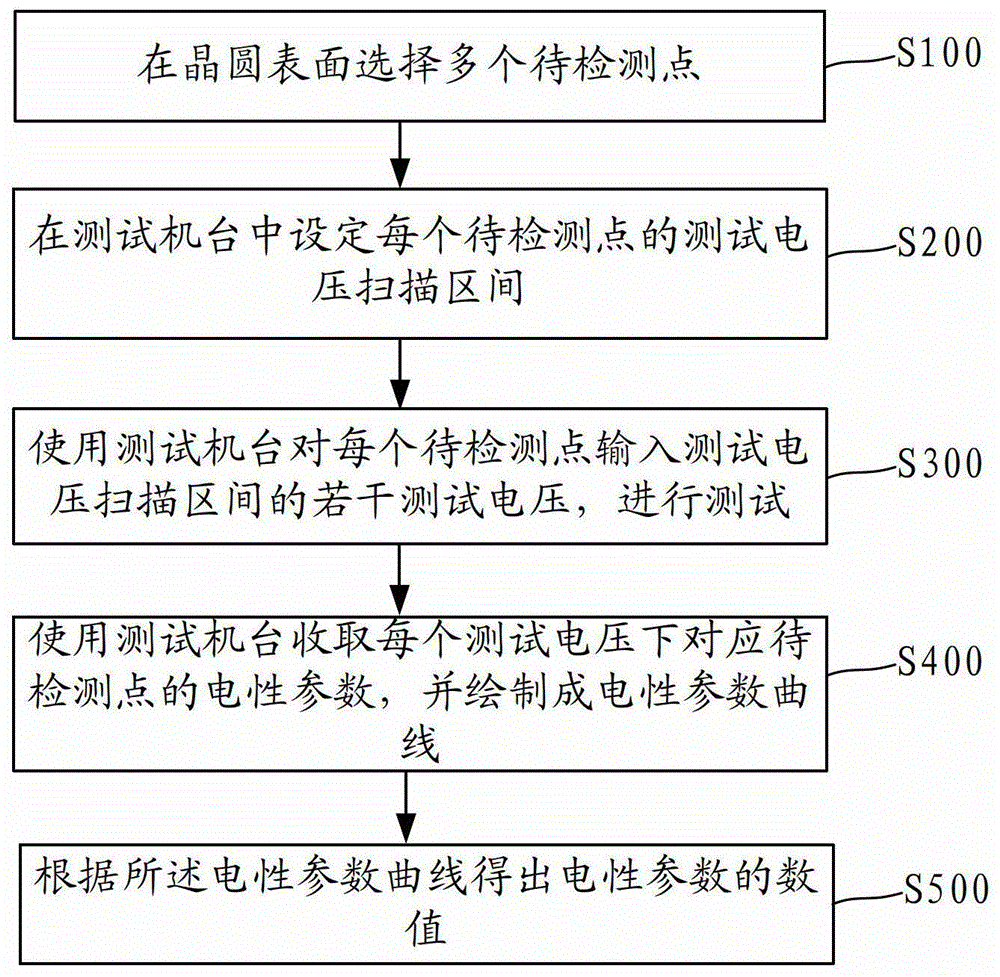

[0026] Please refer to figure 1 , the wafer acceptance test method proposed in this embodiment includes:

[0027] Step S100: Select a plurality of points to be detected on the surface of the wafer; wherein, the wafer is provided with a plurality of dicing lines, and the points to be detected are all set on the dicing lines; the number of points to be detected is 5, evenly distributed on the surface of the wafer;

[0028] Step S200: Set the test voltage scanning interval of each point to be tested in the test machine; the test voltage scanning interval is 0V to 5V, and since the working voltage of the device is usually less than 5V, the test voltage scanning interval is selected to be 0V to 5V It is convenient to obtain the electrical parameter values such as the failure voltage of the device; the test voltage is the voltage added to the test structure (test key) by the test WAT;

[0029] Step S300: use the test machine to input a number of test voltages in the test voltage...

Embodiment 2

[0035] The wafer acceptance testing method proposed in this embodiment is completely the same as the steps in the first embodiment. Please refer to the first embodiment for the specific implementation steps, and will not repeat them again.

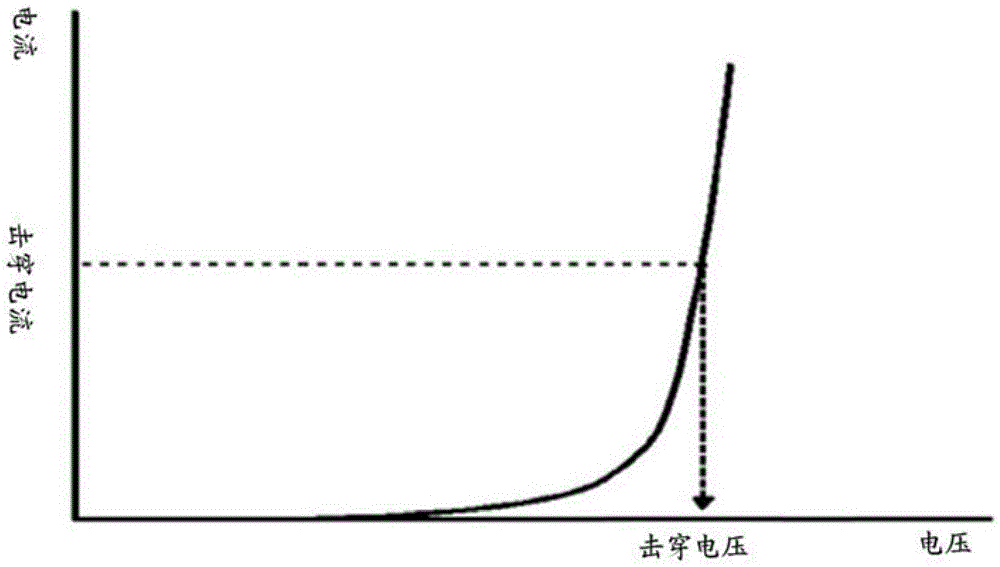

[0036] In this embodiment, the test machine is used to test the wafer and collect the curve of breakdown voltage Bvds between source and drain, please refer to image 3 ;

[0037] From the curve of the breakdown voltage Bvds between the source and the drain, the change of the breakdown voltage Bvds can be observed, and the voltage value of the breakdown voltage Bvds when the target drain current Ids is reached can be returned from this curve, that is, In this embodiment, the electrical parameter to be detected is the voltage value of the breakdown voltage Bvds when the target current is Ids; when the test machine cannot return to the breakdown voltage Bvds when the target drain current Ids is tested or the test machine If an alarm occurs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com