Feeding device for fasteners

A technology for feeding devices and fasteners, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of complex and heavy mechanism, inconvenient use, and high cost, and achieve high control accuracy, reduce wear, and weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

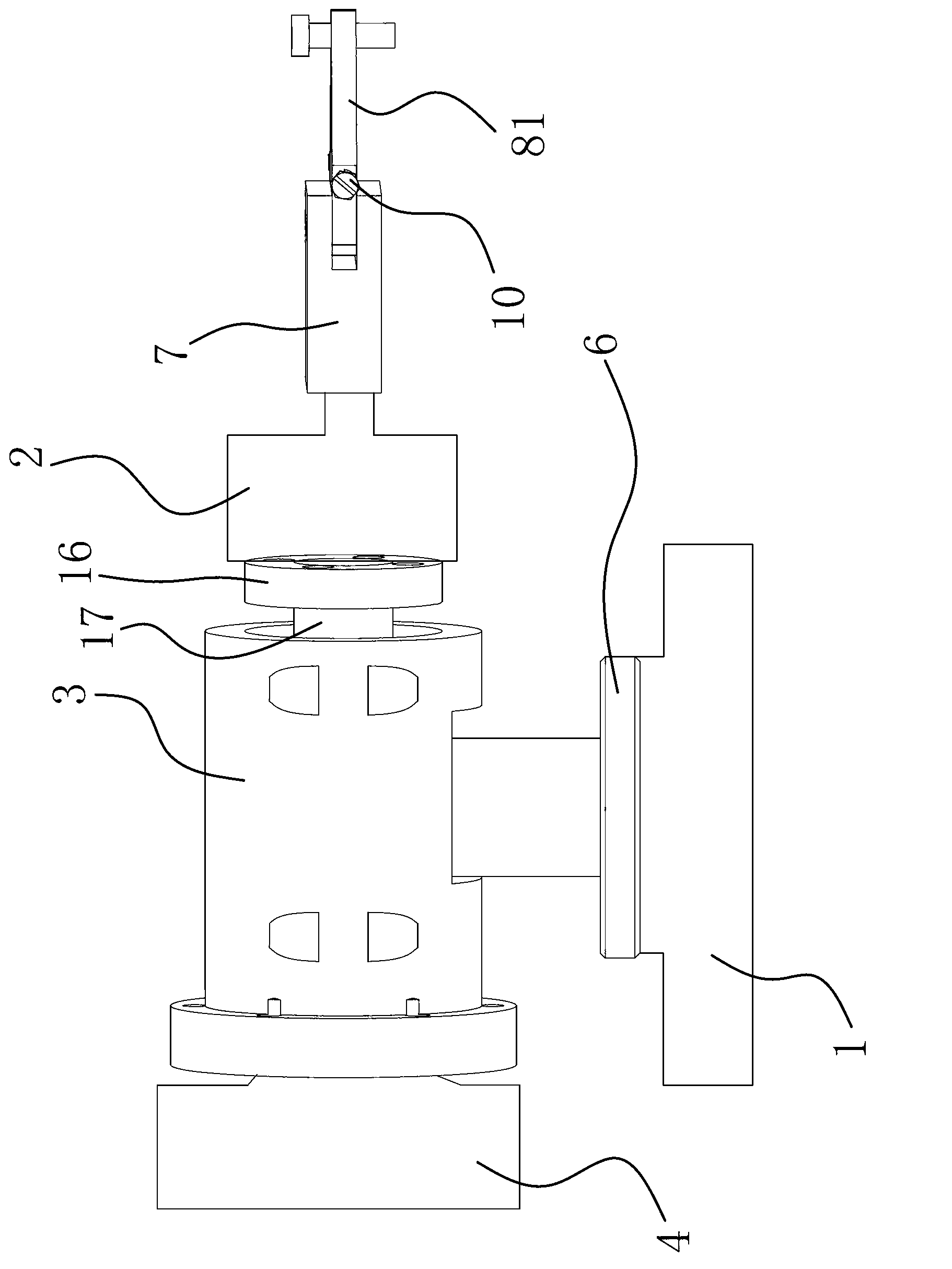

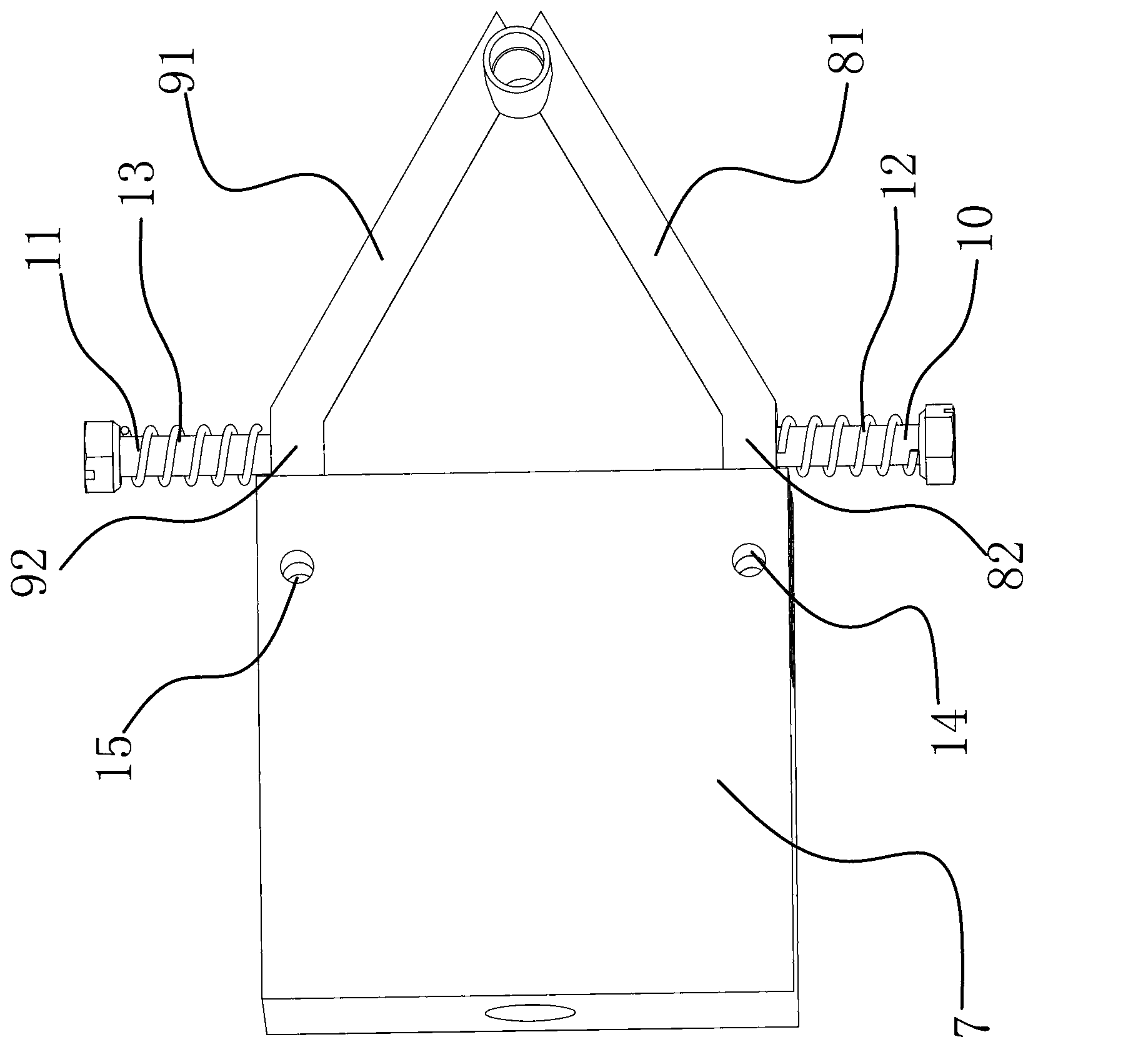

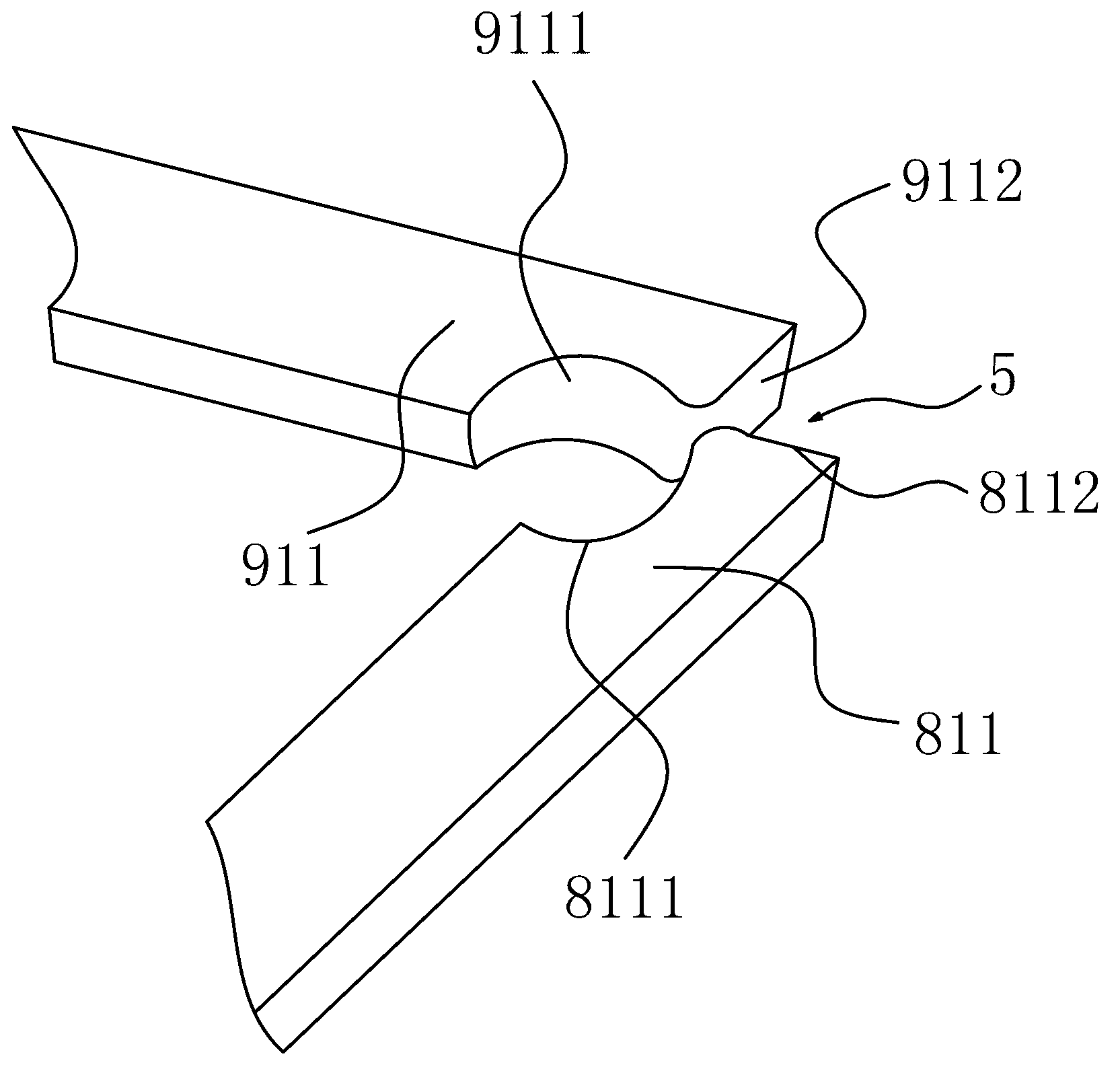

[0025] Such as figure 1 As shown, a feeding device for fasteners includes a base 1, and the base 1 is provided with a telescopic cylinder 2 and a shaft sleeve 3, and the end of the piston rod of the telescopic cylinder 2 is provided with a The clamping mechanism of the firmware, the shaft sleeve 3 is provided with a bearing, the outer ring of the bearing is fixed on the inner wall of the shaft sleeve 3, and the cylinder body of the telescopic cylinder 2 is fixed on the inner ring of the bearing , the axis line of the bearing is parallel to the telescopic direction of the piston rod of the telescopic cylinder 2, and the shaft sleeve 3 is also provided with a rotating mechanism that can drive the inner ring of the bearing to rotate, and the base 1 is also provided with A second rotating mechanism capable of driving the shaft sleeve 3 to rotate in the horizontal direction is provided.

[0026] The rotating mechanism includes a PLC programmable controller and a swing cylinder 4, ...

Embodiment 2

[0039] The content in this embodiment is roughly the same as that in the first embodiment, the difference is that the rotating mechanism in the first embodiment includes a PLC programmable controller and a swing cylinder-4, and the PLC programmable controller is fixed on On the base 1, the cylinder body of the swing cylinder-4 is fixed on the shaft sleeve 3, the output shaft of the swing cylinder-4 is fixedly connected with the inner ring of the bearing, and the The swing cylinder one 4 is connected with the described PLC programmable controller through the line one. The second rotating mechanism is the swing cylinder 6, the cylinder body of the swing cylinder 6 is fixed on the base 1, the output shaft of the swing cylinder 6 is fixed on the above-mentioned axle sleeve 3, and the swing cylinder The output shaft of the second 6 is perpendicular to the axial direction of the axle sleeve 3, and the said swing cylinder 2 6 is connected with the above-mentioned PLC programmable con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com