Device and method for metering and distributing powder

A dispensing device and powder technology, applied in baking, dough processing, food science, etc., can solve the problems of time-consuming efficiency, complex structure, inconvenient use, etc., and achieve strong practicability, high work efficiency, and ingenious structural layout reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

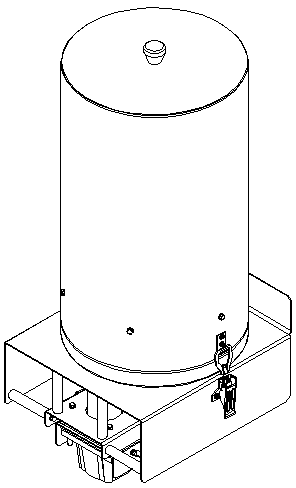

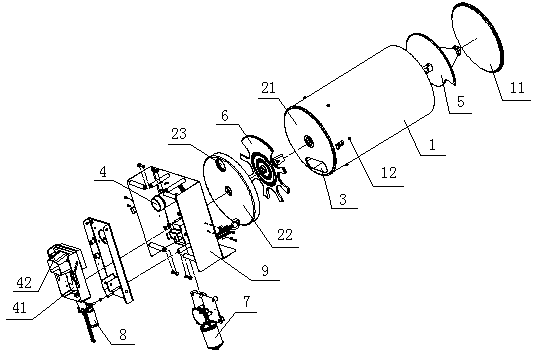

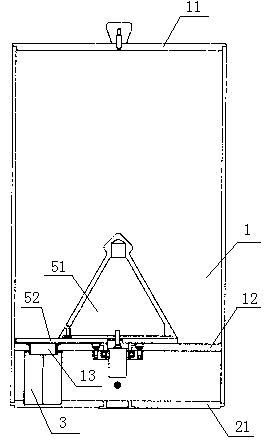

[0027] see figure 1 , figure 2 , image 3 , as shown in the figure, the figure shows a device for implementing metered distribution of powder according to the present invention. The device includes an upper cavity 1 , a lower cavity 2 , a connecting sink 3 and a measuring cup 4 .

[0028] The upper cavity 1 is a cylindrical cavity, including an upper cavity upper cover 11 and an upper cavity bottom cover 12. The upper cavity bottom cover 12 is provided with an upper cavity bottom hole 13, and the upper cavity is provided with a powder pusher 5. The powder to be distributed is placed in the upper cavity, and the powder is usually a powdery raw material mixed according to the existing raw material ratio. The powder pusher is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com