Intelligent row drilling processing production line

A production line and drilling processing technology, which is applied in the field of intelligent row drilling processing production line, can solve the problems of unrealized stroke, influence on efficiency, angle deflection of transmission screw, etc., achieve ingenious and reasonable structural layout, improve accuracy and efficiency, and flexible stroke controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

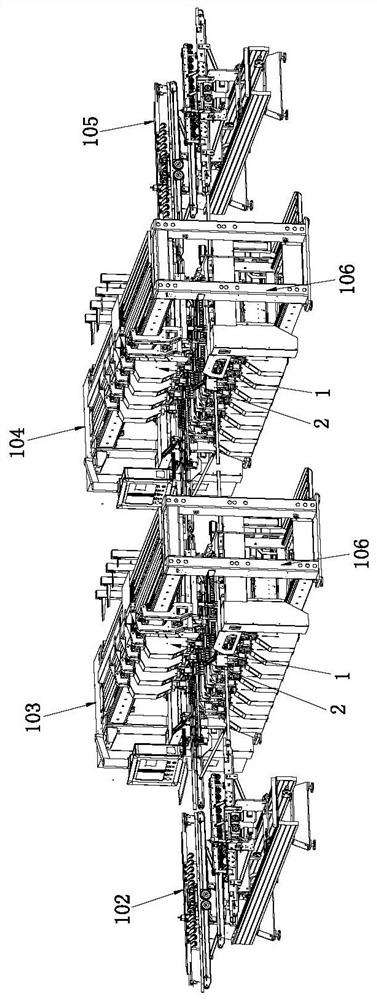

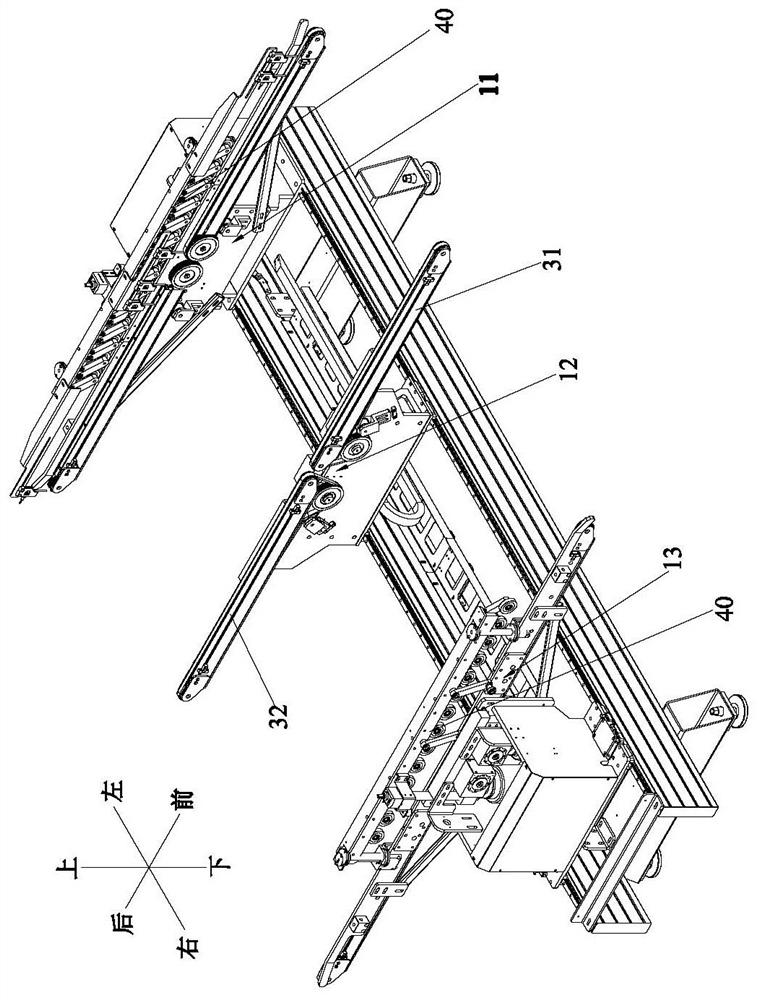

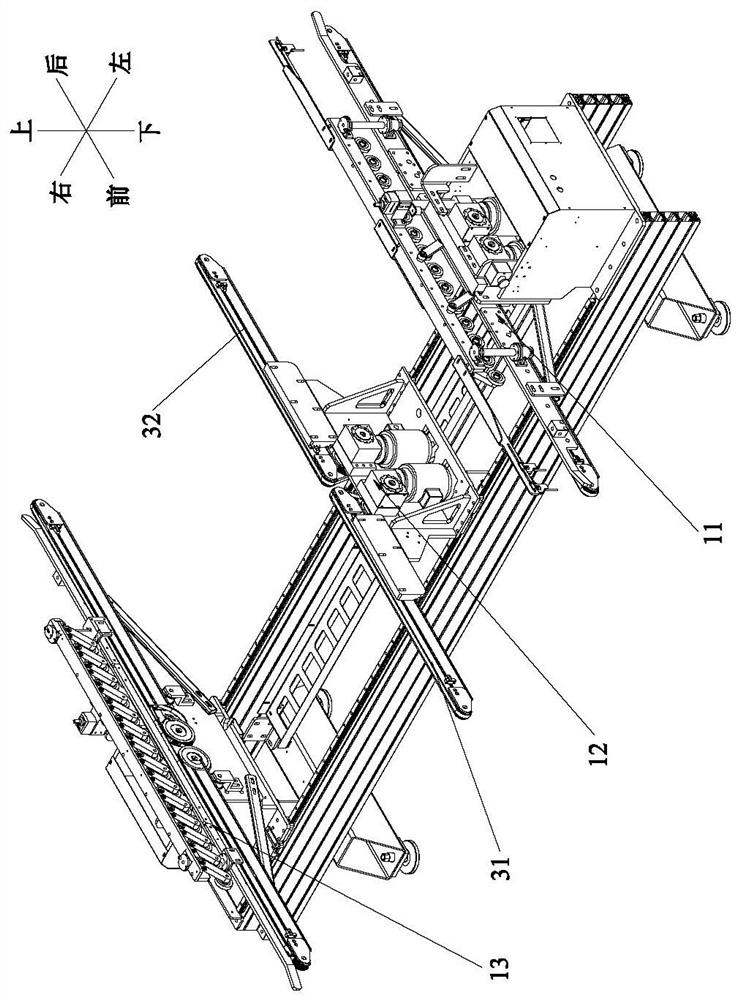

[0087] Please refer to Figure 1 to Figure 14 As shown, it shows the specific structure of the embodiment of the present invention.

[0088] An intelligent row-drilling processing production line, which sequentially includes a first two-stage shifting table 101, a first row-drilling device 102, a second row-drilling device 103, and a second two-stage shifting table 104 according to the sequence of the process; wherein, the The first two-stage transmission platform 101 and the second two-stage transmission platform 104 are of the same structure, and the first row of drilling devices 102 and the second row of drilling devices 103 are of the same structure. The first row of drilling devices 102, the second row of drilling devices 103, and the second two-stage transmission platform 104 are all connected to a main control device.

[0089] Specifically, each two-stage transmission platform includes a support frame, and the support frame includes a first feeding section 31 and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com