Wide-film wide-blade tube and bar piece packaging machine and horizontal packaging method

A technology of packaging machine and pipe stick, which is applied in the field of packaging, can solve the problems of equipment instability, low efficiency, and easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution will be described in detail below in conjunction with specific embodiments.

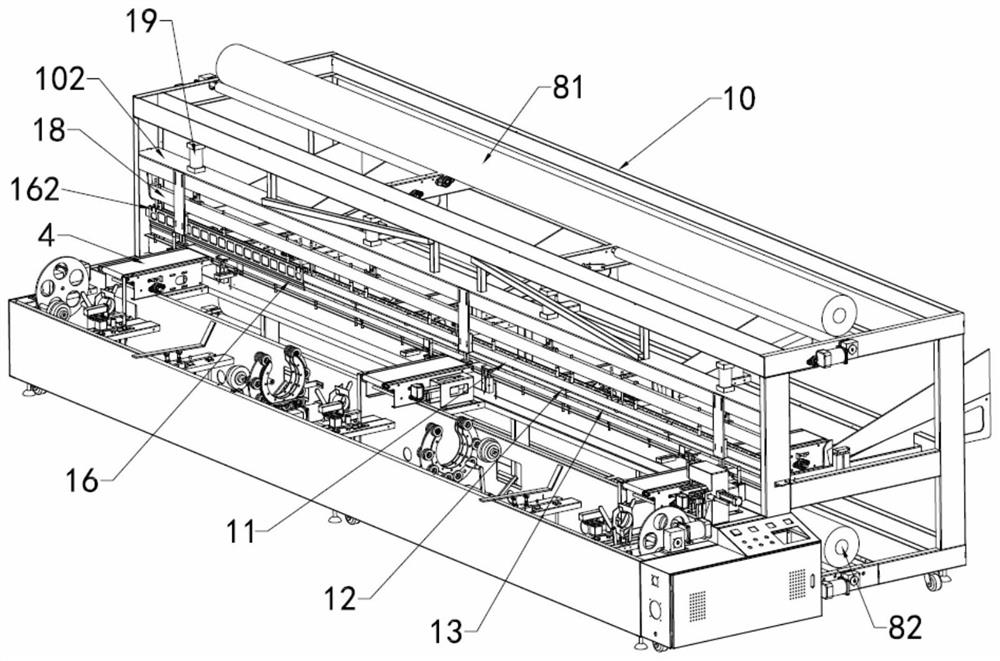

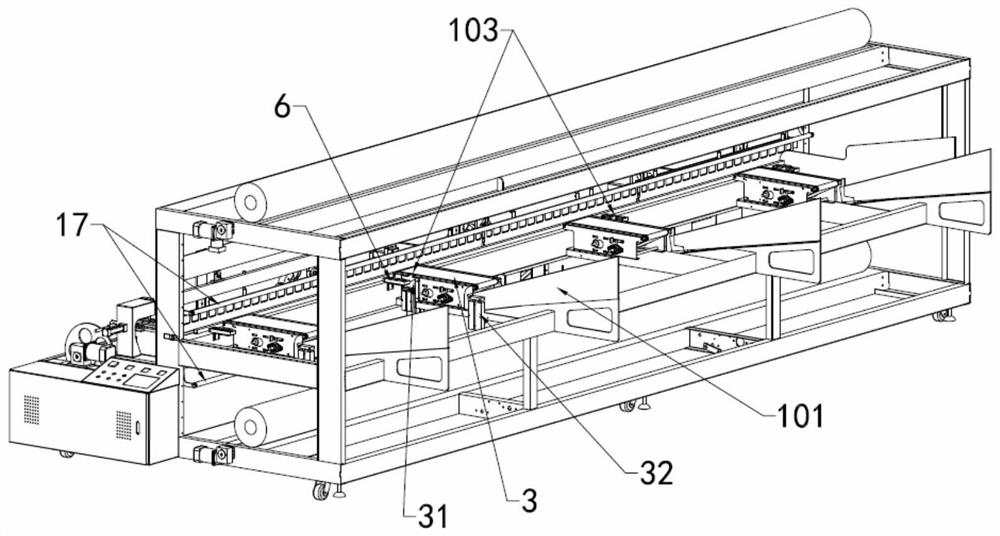

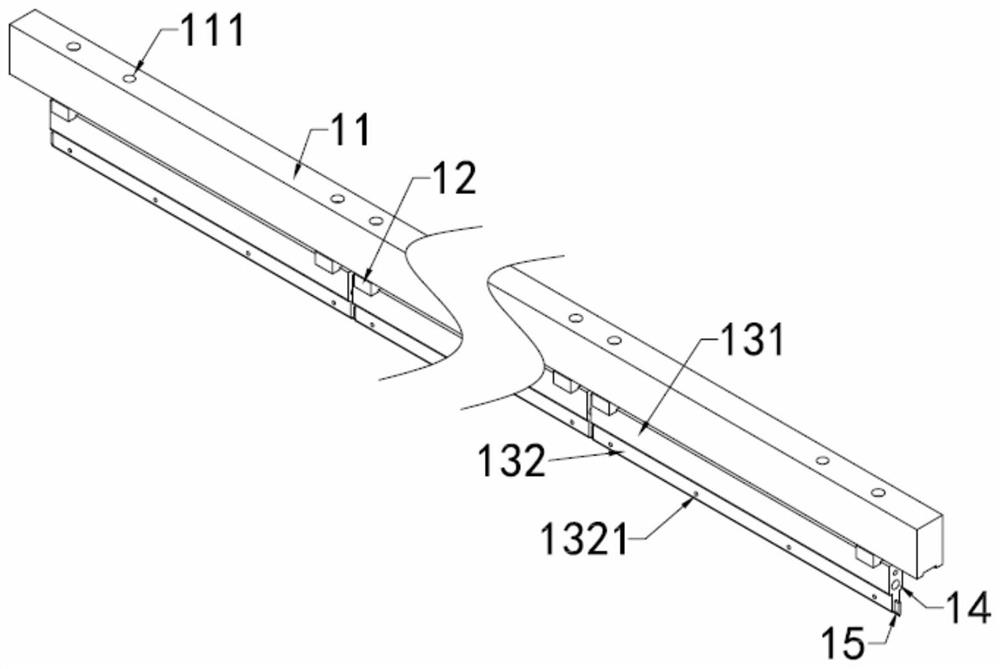

[0031] Such as Figure 1-6 As shown, the present invention discloses a wide-film wide-knife tube rod packaging machine, which includes a frame 10, an upper film feed roller and an upper film roll 81, a lower film feed roller and a lower film roll 82, and an upper cutter. Three to four front conveyor belts 3 are arranged on the front side, three to four rear conveyor belts 4 are arranged on the rear side of the frame, the upper film feeding roller is set above the front conveyor belt 3, and the lower film feeding roller is set below the front conveyor belt 3 , knife rest suspension beam 102 is set on the frame, some first air cylinders 19 are installed on the knife carriage suspension beam, the push rod end of the first air cylinder 19 passes knife rest suspension beam 102, is fixedly connected with upper cutter beam 18; upper cutter beam 18 The upper cutter is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com