Nozzle

A nozzle and main body technology, applied in the field of nozzles for jetting fluids, can solve problems such as detrimental maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

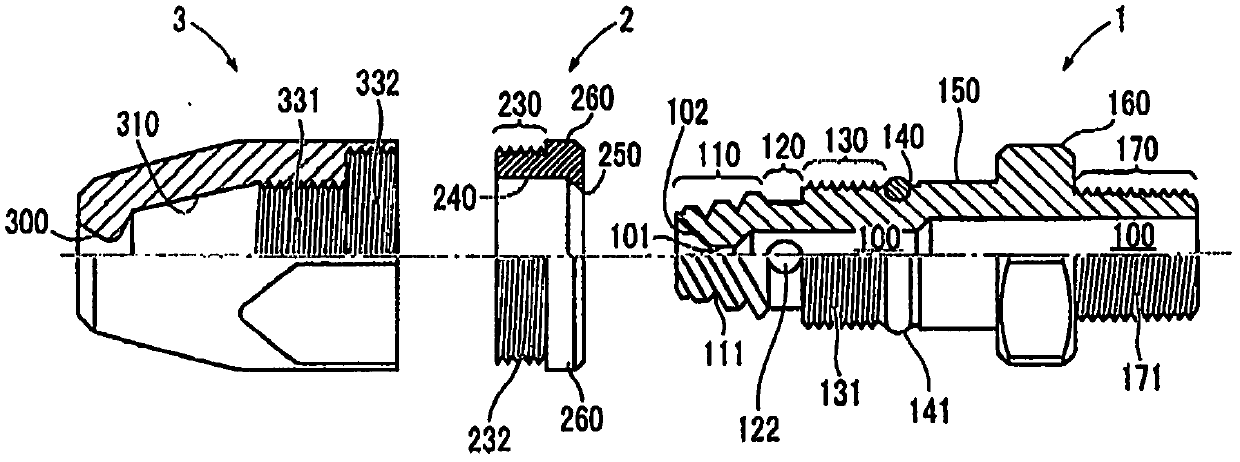

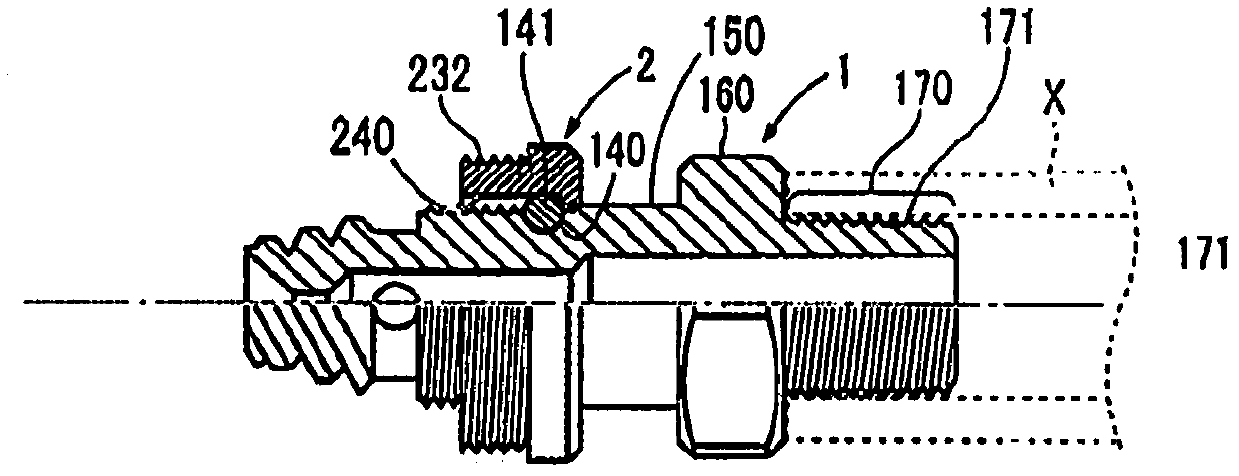

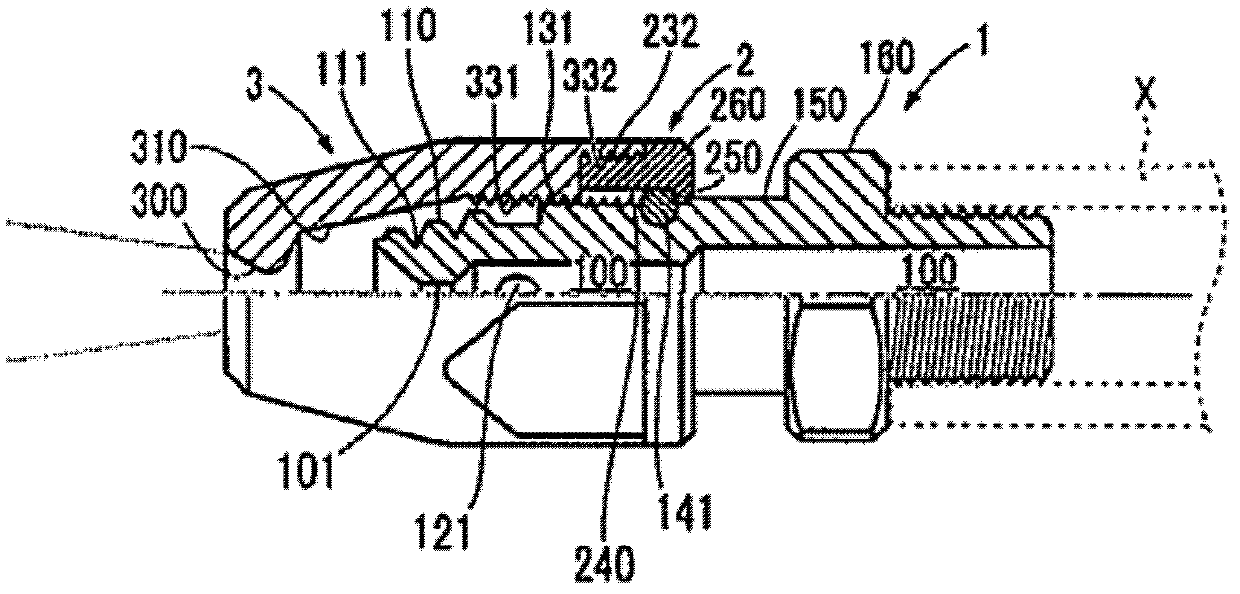

[0038] Such as figure 1 As shown, the nozzle of this embodiment is a nozzle for injecting fluid, and has a nozzle body 1 , a ring member 2 , and a nozzle cover 3 .

[0039] First, the nozzle body 1 will be described. The nozzle body 1 is a tubular member as a whole connected to a supply pipe X (see FIG. 2 ) for supplying fluid. In the present embodiment, the nozzle main body 1 is a member made of metal (made of stainless steel), but the material may be, for example, ceramics or synthetic resin.

[0040] First, there is a central pipe 100 extending along the central axis of the nozzle body 1 and communicating with the supply pipe X in the inner surface of the nozzle body 1 . Here, the inner diameter of the central pipe 100 decreases stepwise from the rear end side for connecting the supply pipe X toward the front end side and has a front end through hole 101 penetrating the front end side, and the front end of the front end through hole 101 is formed to expand in diameter. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com