Method for positioned welding annealing furnace wall brick metal draw hook piece

A metal pull hook piece, positioning welding technology, applied in the direction of welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of excessive deviation of positioning welding of metal pull components, easy to appear empty pull, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

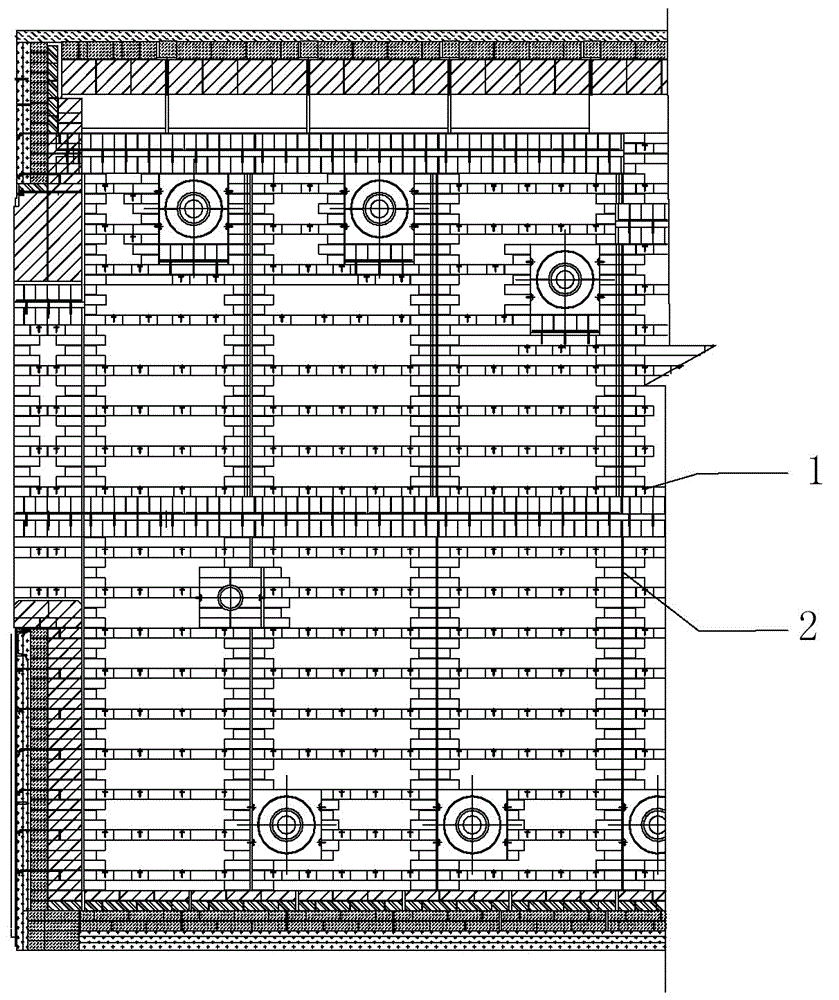

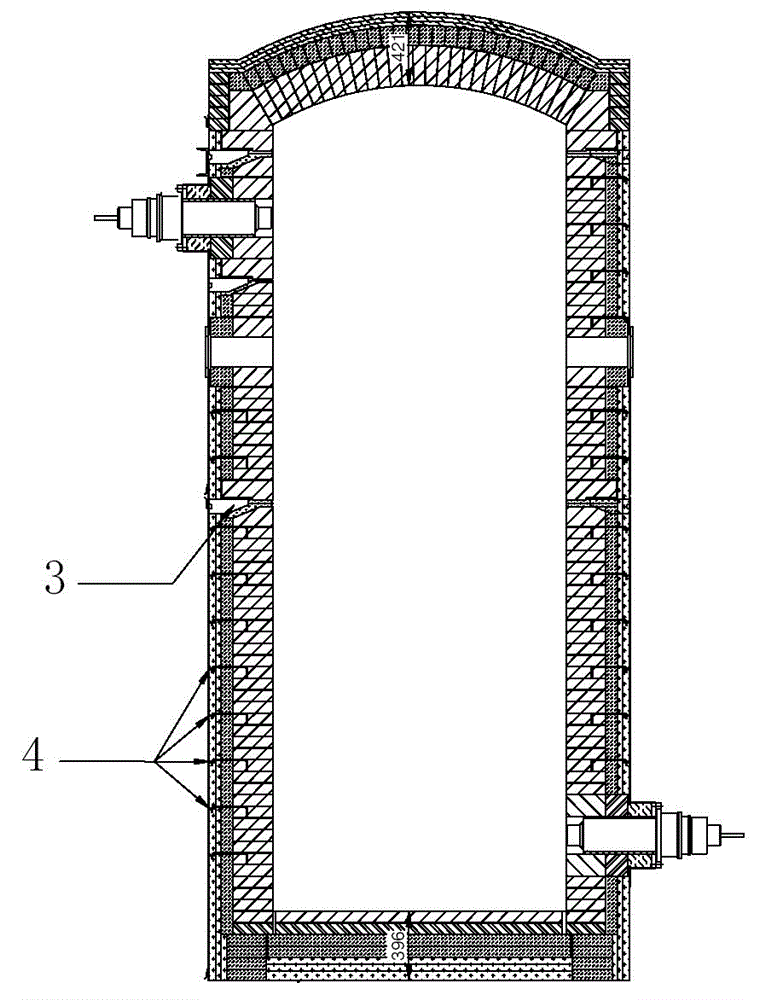

[0027] see now figure 1 and figure 2 , figure 1 It is a plan layout diagram of the wall brick drawing member of the annealing furnace according to the embodiment of the present invention, figure 2 It is a cross-sectional layout diagram of the first section of the annealing furnace wall brick drag hook part of the embodiment of the present invention. As shown in the figure, the drying section of the annealing furnace is 28m long, the furnace wall is 5.423m high, the supporting brick boards 3 are arranged in three layers, and there are 3340 metal drawing members 4 in total.

[0028] The positioning welding method of metal pull hook parts of annealing furnace wall brick of the present invention is characterized in that it comprises the following steps:

[0029] a. Set masonry datum line and masonry size

[0030] According to the installation drawing of the furnace shell of the annealing furnace, measure the internal space size of the furnace shell, calculate the deviation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com