Detachable antiskid mechanism of manipulator

A manipulator, anti-slip technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of increased friction and easy falling off of the clamped objects, and achieve the effects of increased friction, convenient maintenance and replacement, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

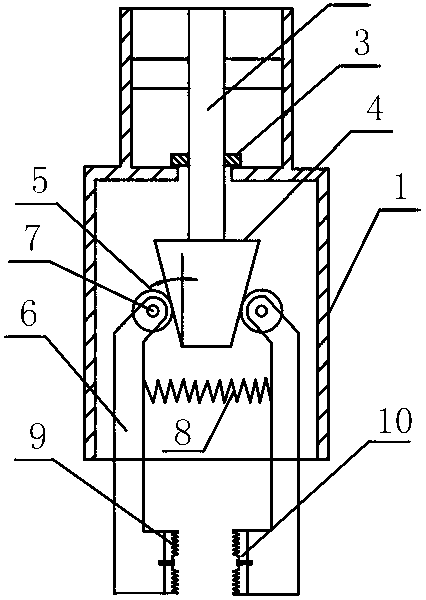

[0021] Such as figure 1 As shown, the detachable anti-skid mechanism of the manipulator of this embodiment includes a clamping mechanism body 1, a control rod 2, a limit block 3, a wedge 4, a rotating roller 5, a clamping arm 6, a bolt, an anti-skid fast 10, and a rotating roller 5 is installed inside the clamping mechanism body 1 and can rotate along the installation axis. There is also a through hole in the clamping mechanism body 1. One end of the control rod 2 is fixedly connected to the wedge 4 through the through hole, and the other end is connected to the driving mechanism. The driving mechanism constitutes a control mechanism that controls the slope of the wedge 4 away from the rotating roller 5 or close to and supports the rotating roller 5, and the outer wall of the control lever has a protruding stopper 3, and one end of the clamping arm 6 is connected to the rotating roller 5. Fixed connection, the other end of the clamping arm 6 constitutes the clamping end, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com