Adhesion apparatus and adhesion method

A bonding device, display device technology, applied in lamination devices, chemical instruments and methods, lamination auxiliary operations, etc., can solve problems such as damage to the uniformity of bonding thickness, adhesive cushioning and viscosity loss, difficulties, etc. , to achieve uniform adhesive thickness and prevent overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention (hereinafter referred to as embodiments) will be specifically described with reference to the drawings.

[0039] [A. Composition]

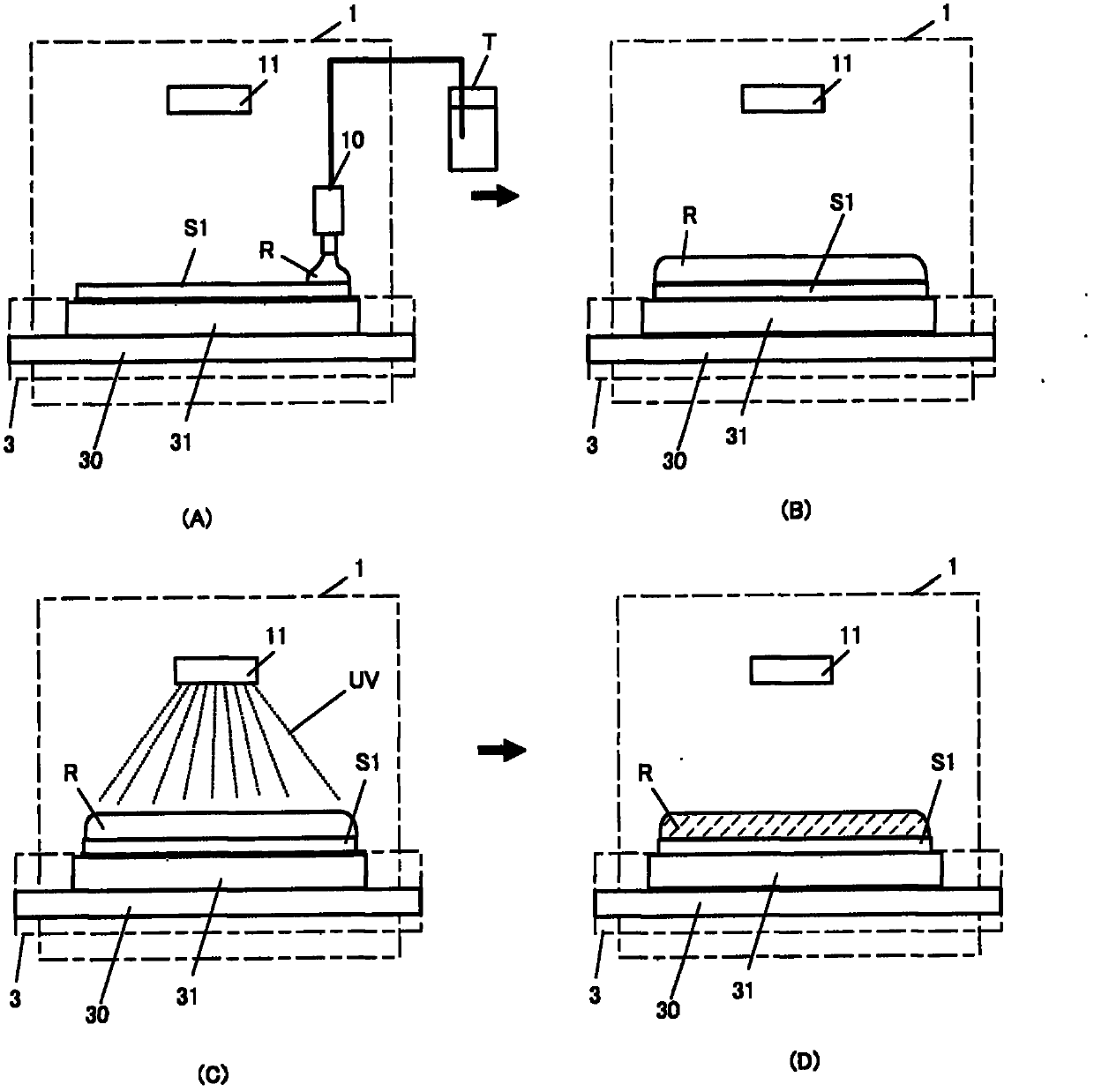

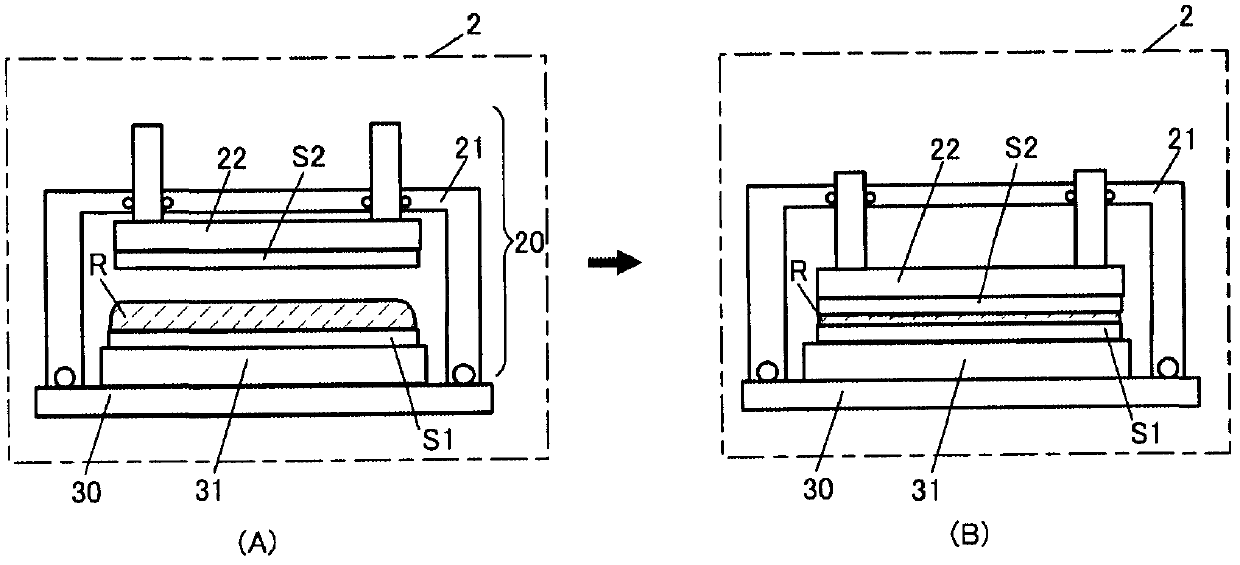

[0040] First, the configuration of the adhesive supply device (hereinafter referred to as the present device) of the present embodiment will be described. This device is figure 1 as well as figure 2 As shown, it has an adhesive supply part 1, a bonding part 2, and the like. The workpiece S1 to be bonded is provided so as to be movable between the adhesive supply part 1 and the bonding part 2 by the conveyance part 3 .

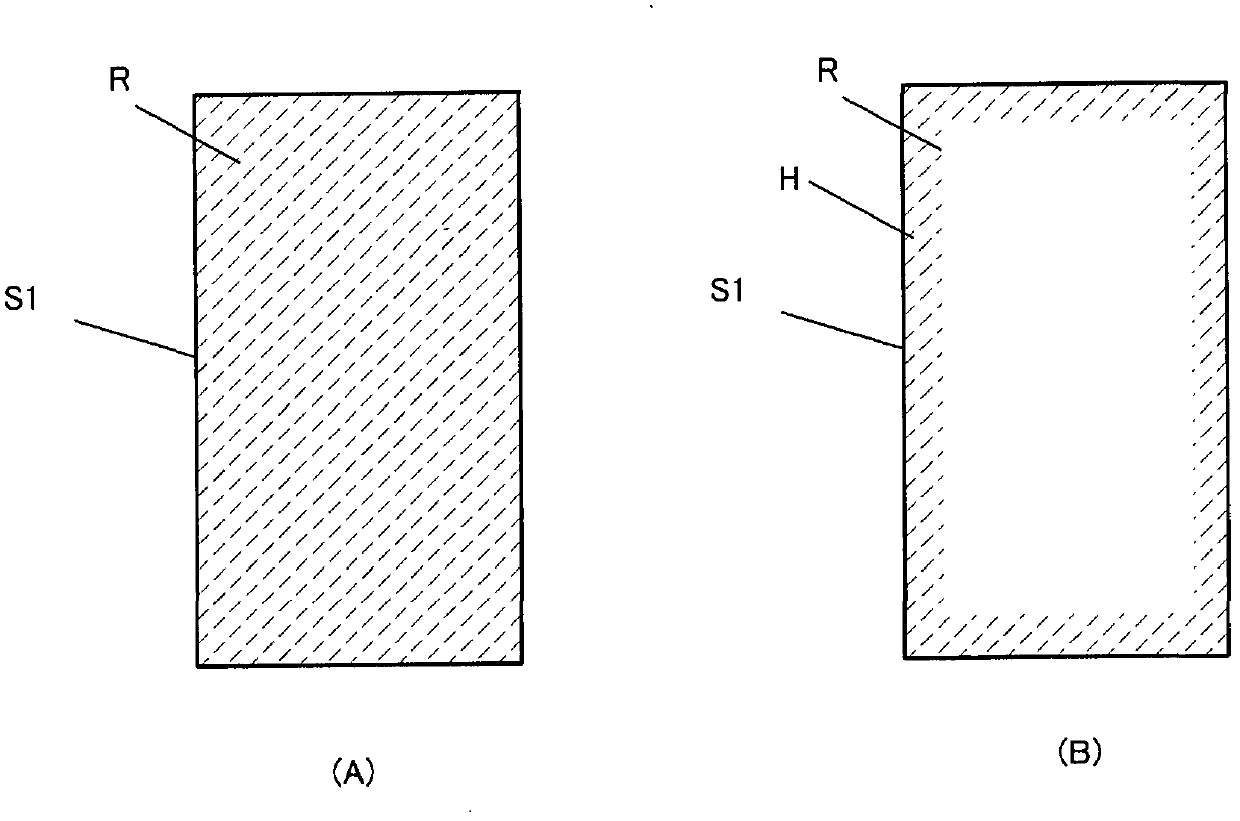

[0041] As the adhesive used in the present embodiment, for example, an ultraviolet (UV) curable resin may be used. Adhesive supply part 1 such as figure 1 Shown is a supply section 10, an irradiation section 11, and the like. The supply unit 10 includes, for example, a dispenser that drips the adhesive R stored in the tank T onto the workpiece S1 via a pipe. The dispenser is confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com