Bearing platform type sleeper beam structure for railway vehicle

A technology for rail vehicles and corbels, which is applied in the field of submerged table corbel structures of rail vehicles, can solve the problems of high manufacturing and maintenance costs, and cannot be adapted, and achieves the effects of low cost, reduced manufacturing and maintenance costs, and improved curve passability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

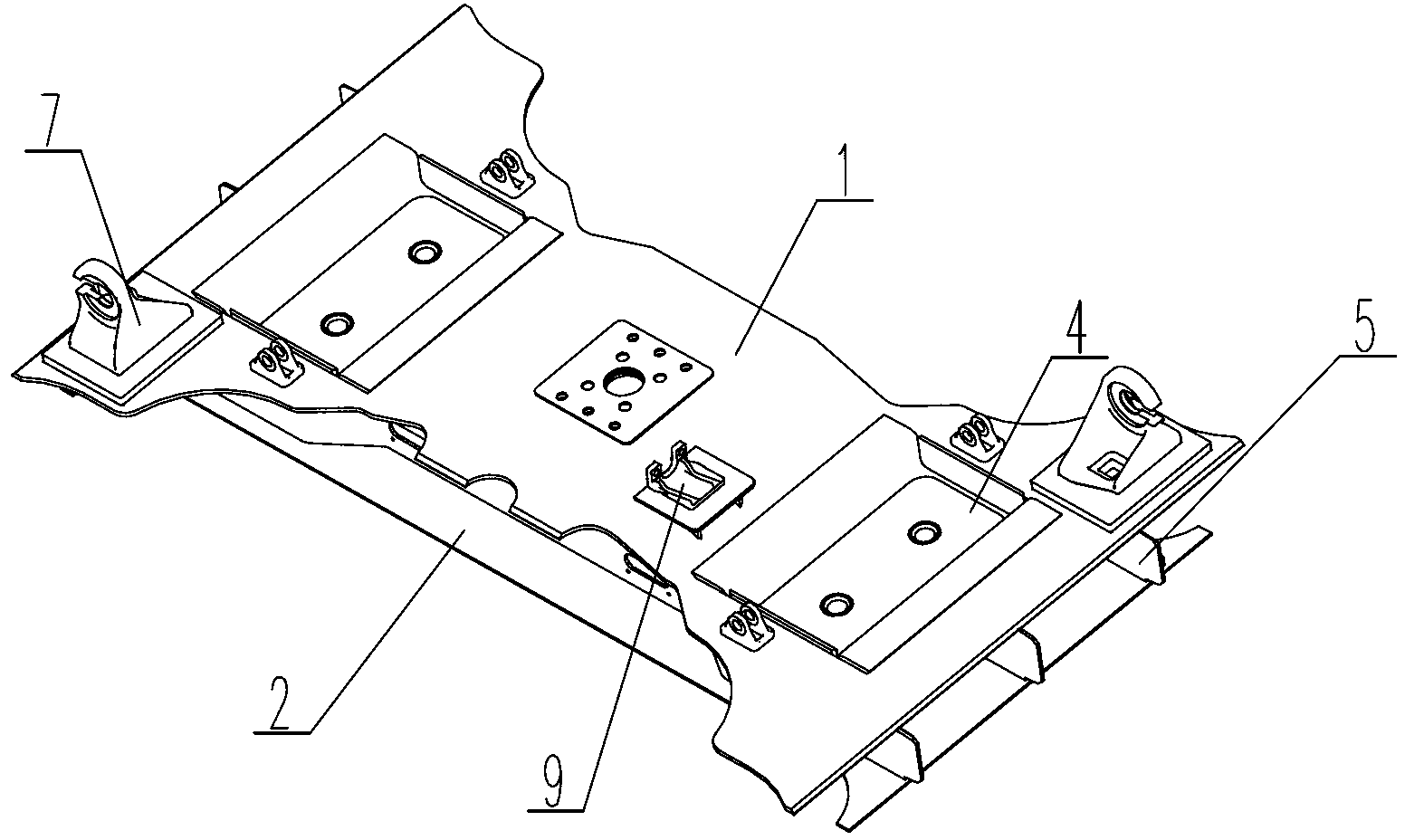

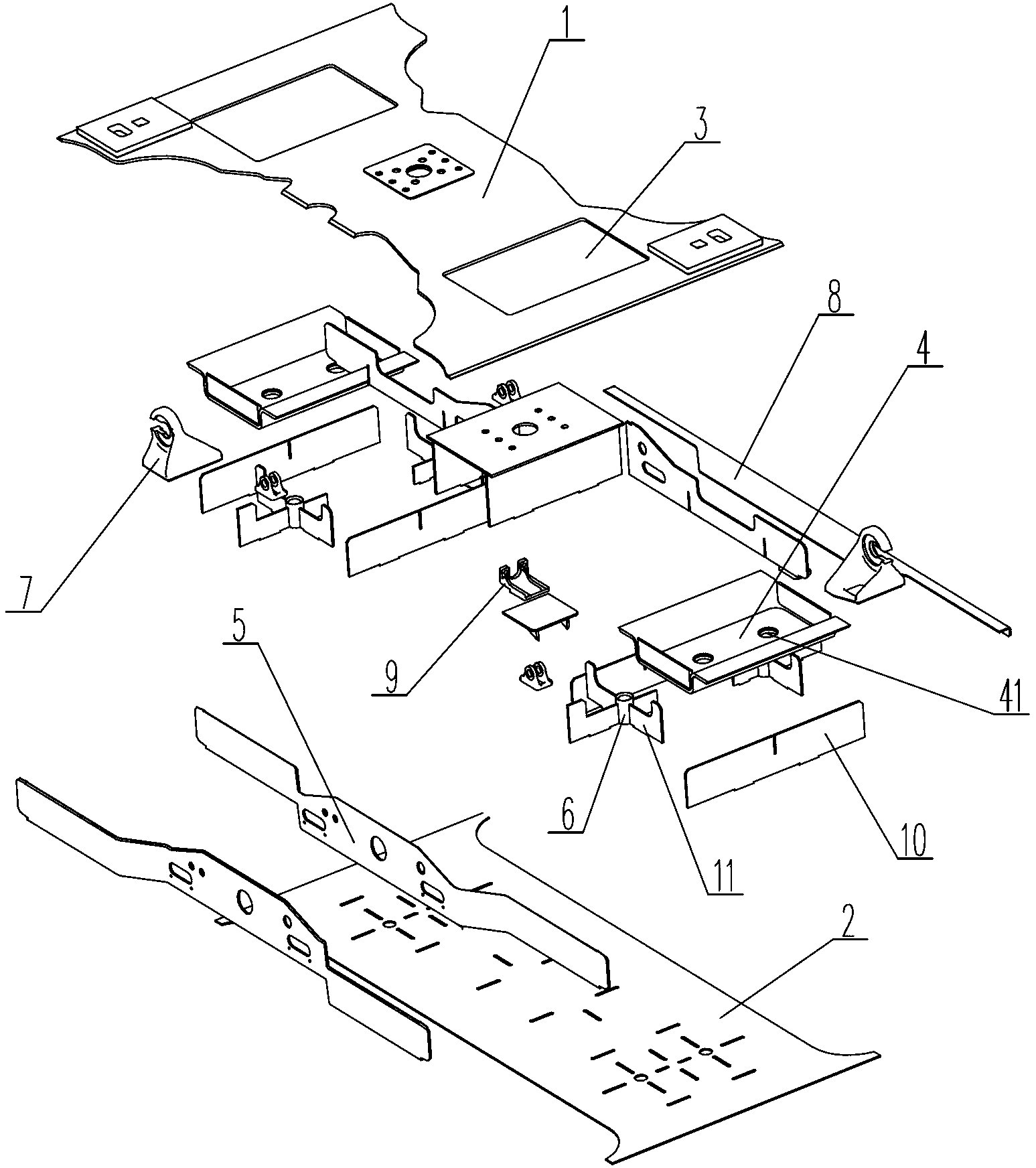

[0018] Such as figure 1 As shown, the sunken platform bolster structure of the rail vehicle in this embodiment consists of: an upper cover plate 2, a lower cover plate 1, and a web 5, and the lower cover plate 2 is provided with a gap 3 corresponding to the secondary steel spring of the bogie, and the position of the gap is An open box body 4 for inserting the upper end of the second series steel spring of the bogie is fixed. The box body 4 is located between the lower cover plate 1 and the upper cover plate 2. The box body 4 cooperates with the gap 3 to form a sinking platform structure. The box body 4 The top is provided with a pin hole 41 for the insertion of the secondary steel spring positioning pin, the back of the box body 4 is fixed with a positioning pin mounting seat 6 for the secondary steel spring positioning pin to be inserted, and the two sides of the corbel are fixed with the traction beam rod seat 7 . In this embodiment, in order to improve the strength of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com