Anti-scaffolding furnace bottom roller used for steel rolling and manufacturing method thereof

A manufacturing method, hearth roll technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems affecting the surface quality of rolled plates, and achieve the solution of roll body nodules, increase the service life, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

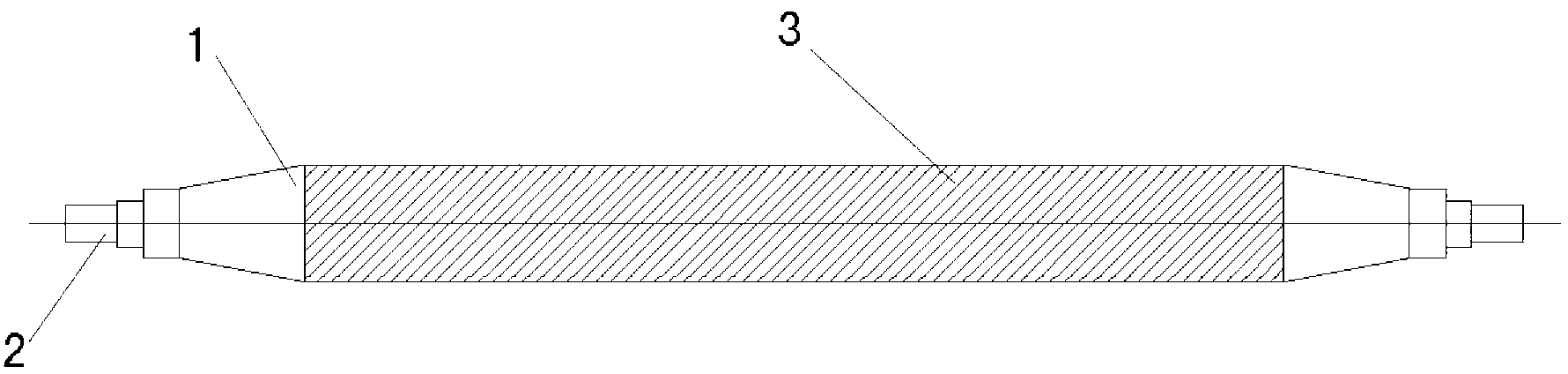

[0026] like figure 1 As shown, an anti-nodulation hearth roll for steel rolling according to the present invention includes a cylindrical hearth roll body 1, both ends of the hearth roll body 1 are provided with support shafts 2, and the furnace The outer surface of the bottom roll body 1 and the outer surface of the support shaft 2 are both sheathed with a carbon-ceramic composite material interlayer 3 .

[0027] The carbon-ceramic composite material interlayer 3 is integrally formed, and the carbon-ceramic composite material interlayer 3 is fitted onto the outer surface of the hearth roll body 1 by means of interference fit.

[0028] In another embodiment, the carbon-ceramic composite material interlayer 3 is a split modular structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com