A low-alloy heat-resistant steel plate and its manufacturing method

A low-alloy, steel plate technology, applied in the field of alloy material manufacturing, can solve problems such as no records, and achieve the effects of corrosion resistance to certain media, high temperature resistance, long-lasting strength, long-lasting plasticity, and stable organizational properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

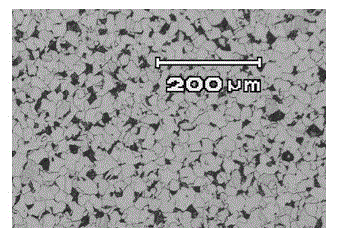

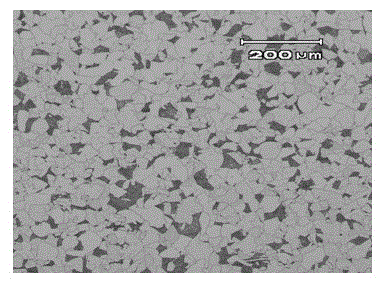

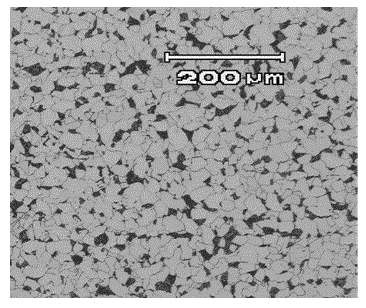

Image

Examples

Embodiment 1

[0031] Embodiment 1: The thickness of the produced steel plate is 80 mm.

[0032] A method for manufacturing a low-alloy heat-resistant steel plate, the steps are as follows:

[0033] 1) Hot metal pretreatment step: Desulfurization by KR hot metal pretreatment, the sulfur content after treatment is 0.003%, the hot metal temperature is 1269°C, and the arsenic content is 0.002%.

[0034]2) Converter smelting and deoxidation alloying steps: Converter smelting: target carbon content at the end point is 0.08%, P: 0.006%, S: 0.005%, and the target tapping temperature is 1620°C; double slag blocking with slag blocking plug and slag blocking rod Tapping; ferromolybdenum is added to the converter along with scrap steel, and ferroalmanganese, lime, and fluorite are added to make top slag during the tapping process; ferrochrome, silicon-manganese alloy, ferroalmanganese, and ferro-vanadium are added in turn for alloying, and the time for blowing argon during tapping is 14 minutes.

[0...

Embodiment 2

[0042] Embodiment 2: The thickness of the produced steel plate is 10mm.

[0043] A method for manufacturing a low-alloy heat-resistant steel plate, the steps are as follows:

[0044] 1) Hot metal pretreatment step: Desulfurization by KR hot metal pretreatment, the sulfur content after treatment is 0.002%, the hot metal temperature is 1250°C, and the arsenic content is 0.001%.

[0045] 2) Converter smelting and deoxidation alloying steps: Converter smelting: the final carbon content is 0.08%, P: 0.006%, S: 0.005%, and the tapping temperature is 1620°C; the slag blocking plug and the slag blocking rod are used to tap double slag blocking ; Ferromolybdenum is added to the converter along with scrap steel, and ferroalmanganese, lime, and fluorite are added to make top slag during the tapping process; ferrochrome, silicon-manganese alloy, ferroalmanganese, and ferro-vanadium are added in turn for alloying, and argon blowing time is 15 minutes during the tapping process .

[0046]...

Embodiment 3

[0053] Embodiment 3: The thickness of the steel plate involved in this embodiment is 40 mm.

[0054] A method for manufacturing a low-alloy heat-resistant steel plate, the steps are as follows:

[0055] 1) Hot metal pretreatment step: Desulfurization by KR hot metal pretreatment, the sulfur content after treatment is 0.003%, the hot metal temperature is 1256°C, and the arsenic content is 0.001%.

[0056] 2) Converter smelting and deoxidation alloying steps: Converter smelting: the final carbon content is 0.08%, P: 0.006%, S: 0.005%, and the tapping temperature is 1625°C; the slag blocking plug and the slag blocking rod are used to tap the steel; Ferromolybdenum is added to the converter along with scrap steel, and ferroalmanganese, lime, and fluorite are added to make top slag during the tapping process; ferrochrome, silicon-manganese alloy, ferroalmanganese, and ferro-vanadium are added in turn for alloying, and argon blowing time is 16 minutes during the tapping process.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com