Large-diameter tube curtain support underground excavation construction super-shallow burying large-section subway station structure and construction method

A technology for subway stations and construction methods, which is applied to earth-moving drilling, underground chambers, mining equipment, etc., can solve the problems of low space utilization rate, and achieve the effect of improving space utilization rate, reducing project cost, and excellent settlement control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] As shown in the figure, taking the realization of underground excavation of a three-story three-span station as an example, the technical solution adopted in this construction method invention includes the following steps:

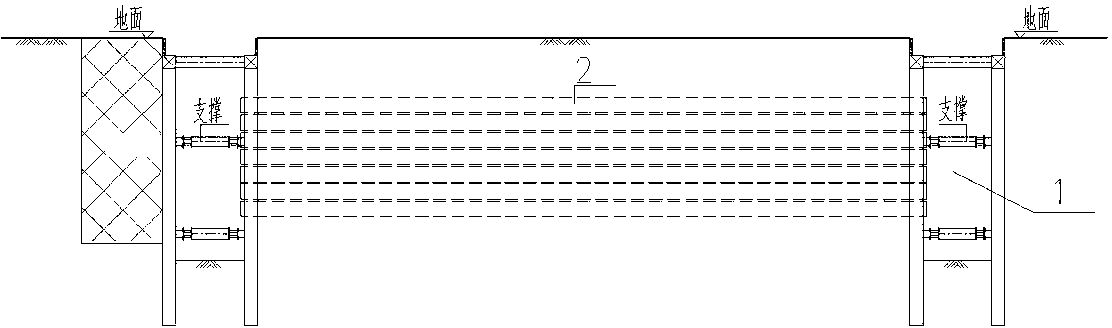

[0040] 1) Excavate and support two working wells 1, the working well 1 is composed of a temporary construction shaft or a station open-cut foundation pit, and its structure is as follows figure 1 , 2 shown;

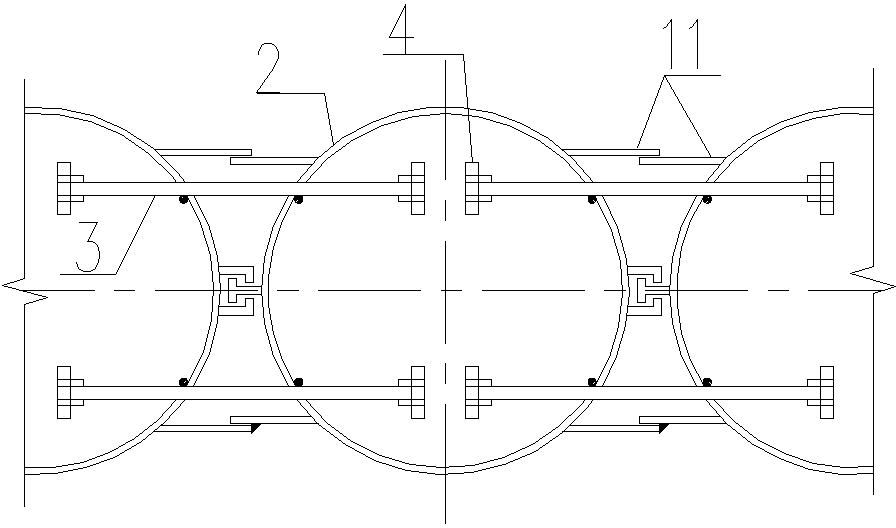

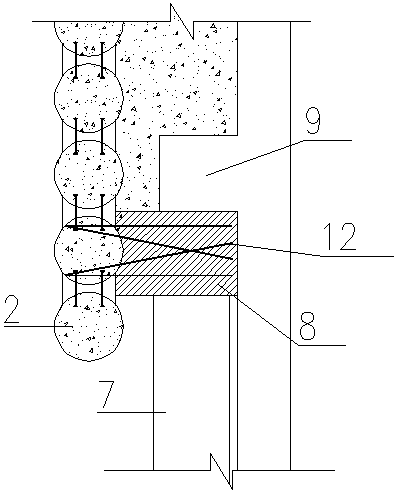

[0041] 2) Processing and manufacturing steel pipe curtain 2, such as figure 2 As shown, the flange plate 11 is welded on the steel pipe curtain 2, and the bolt holes are opened on the steel pipe curtain 2;

[0042] 3) Using the working well 1 as the construction work surface, the steel pipe curtain 2 is jacked horizontally and segmentally by the jack to the design mileage; the steel pipe curtain 2 is about 3m away from the ground; ultra-shallow burial construction operation is realized;

[0043] 4) During the jacking process, the manual so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com