Planetary cone-ring transmission

A technology for planetary cone rings and transmissions, which is applied to gear transmissions, belts/chains/gears, mechanical equipment, etc. It can solve the problems that are difficult to satisfy the power and economy of the whole vehicle at the same time, and achieve a large range of transmission ratio coverage. The effect of light weight and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

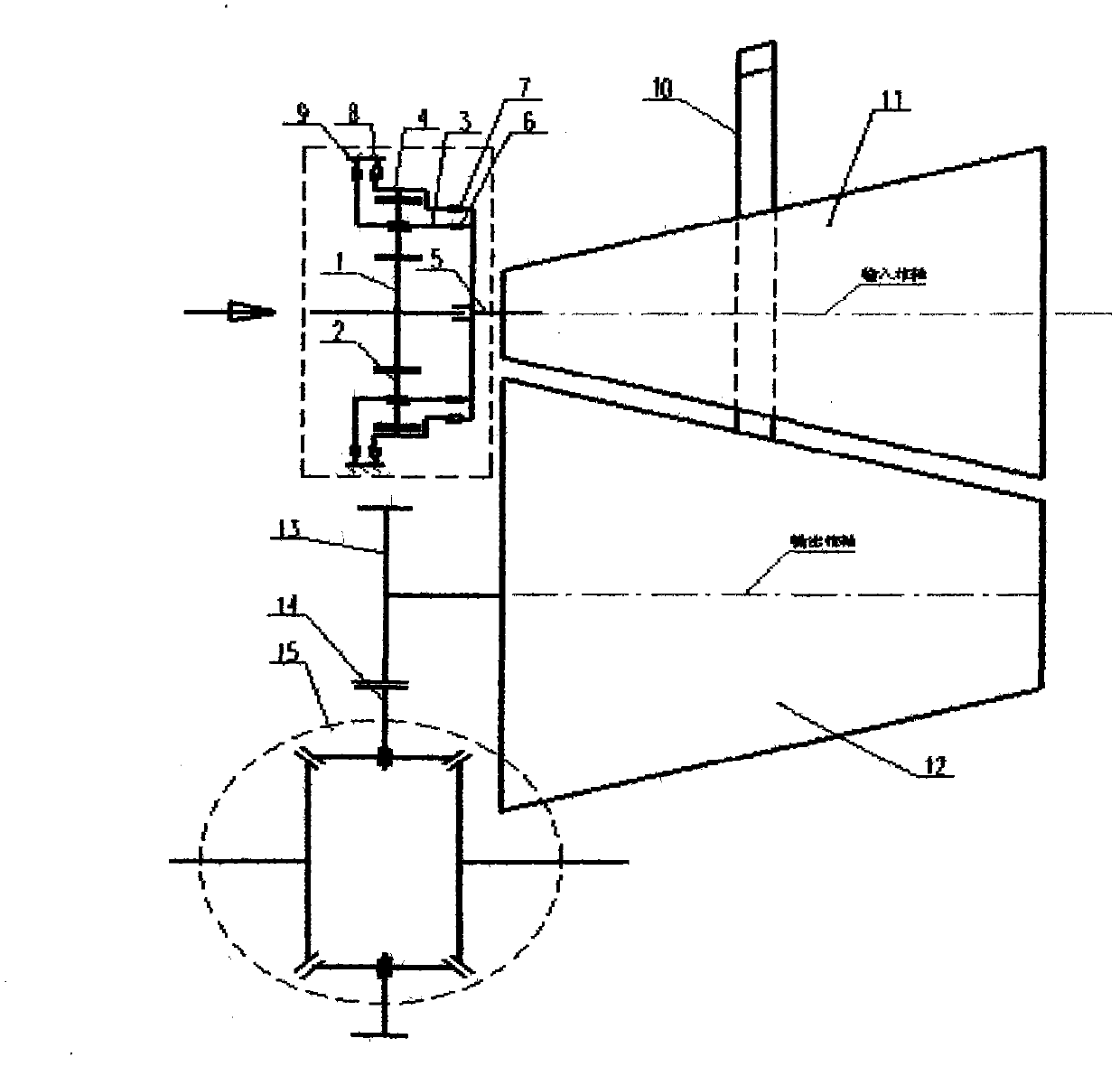

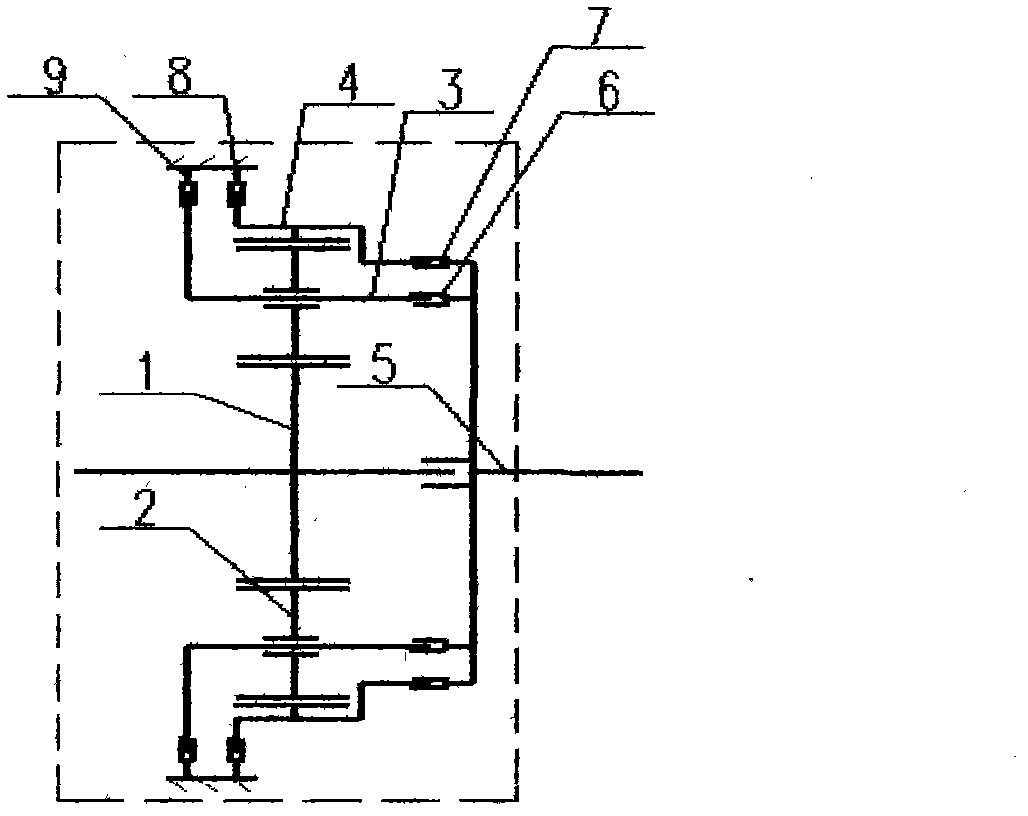

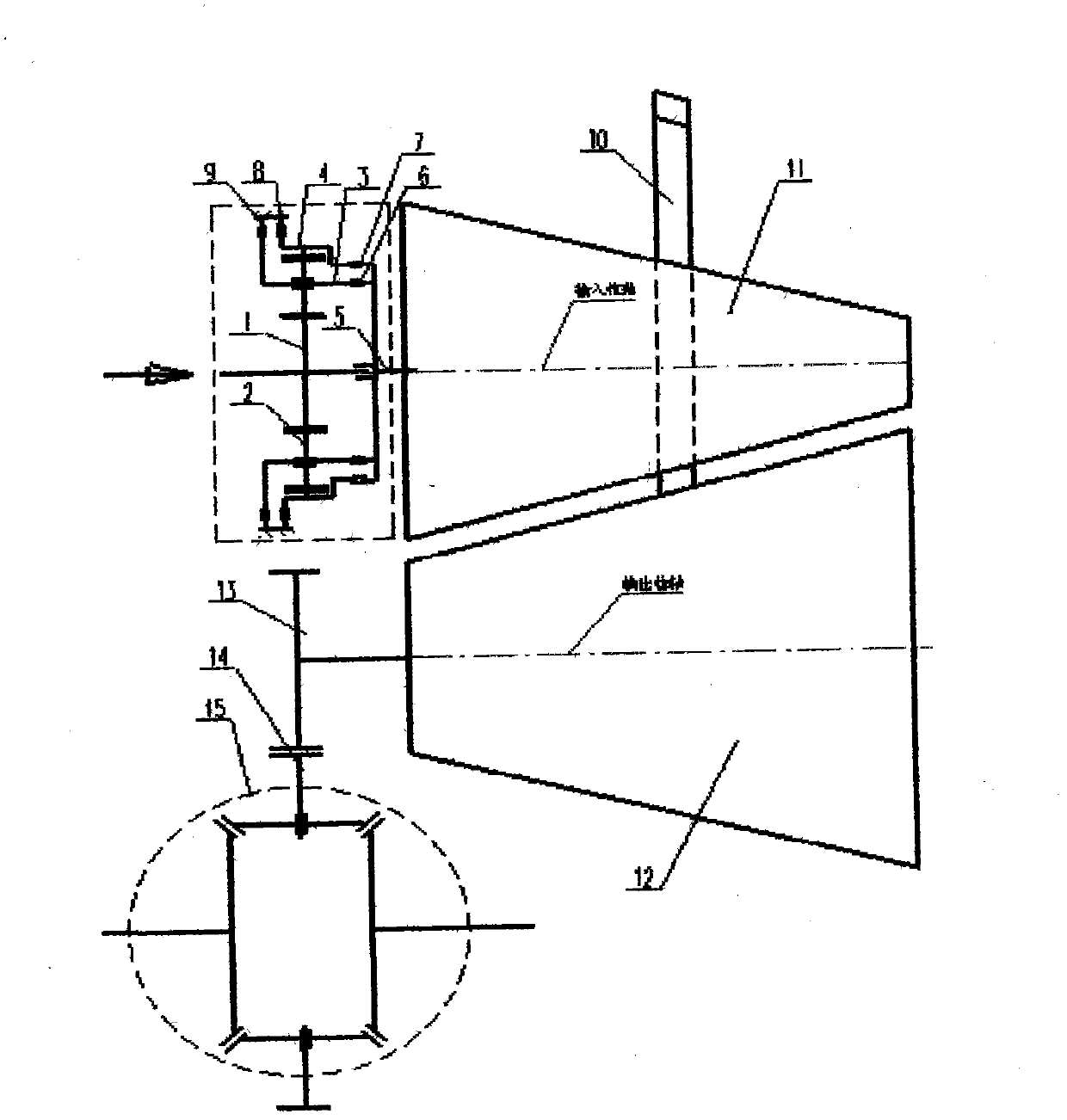

[0017] In the figure, the schematic diagram of the three-speed single-row planetary gear transmission is shown in the square virtual frame, the schematic diagram of the differential is shown in the circular virtual frame, the schematic diagram of the cone-ring continuously variable transmission is composed of the driving cone 11, the ring 10 and the driven cone 12, and the main reducer It consists of main deceleration small teeth 13 and main deceleration large teeth 14.

[0018] Figure 1-5 The working principle of the three-speed single-row planetary gear transmission shown in is: the power is input from the sun gear 1 and output from the output shaft 5. By manipulating four clutches 6, 7, 8, 9, each gear is realized. Neutral: All 4 clutches are disengaged. Forward low gear: clutches 6 and 8 are engaged, and clutches 7 and 9 are disengaged. Forward high gear: clutches 6 and 7 are engaged, clutches 8 and 9 are disengaged, and the speed ratio is 1:1. Reverse gear: Clutches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com