Method for measuring inner stress in pouring explosive solidification process

A technology of internal stress and measurement method, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of harsh environmental requirements, high test cost, inability to measure the internal stress of materials in real time, etc., and achieve the effect of reducing the test cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

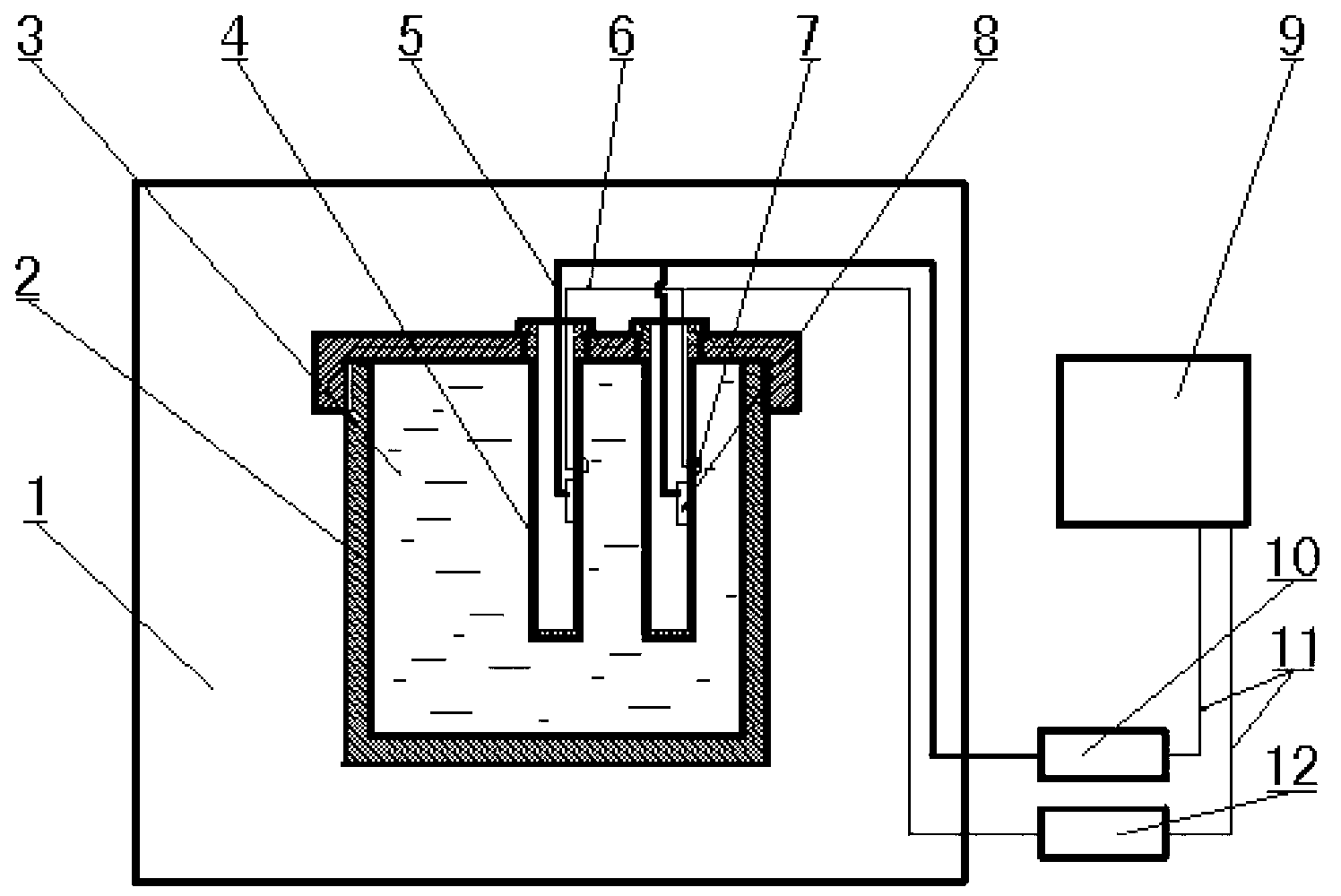

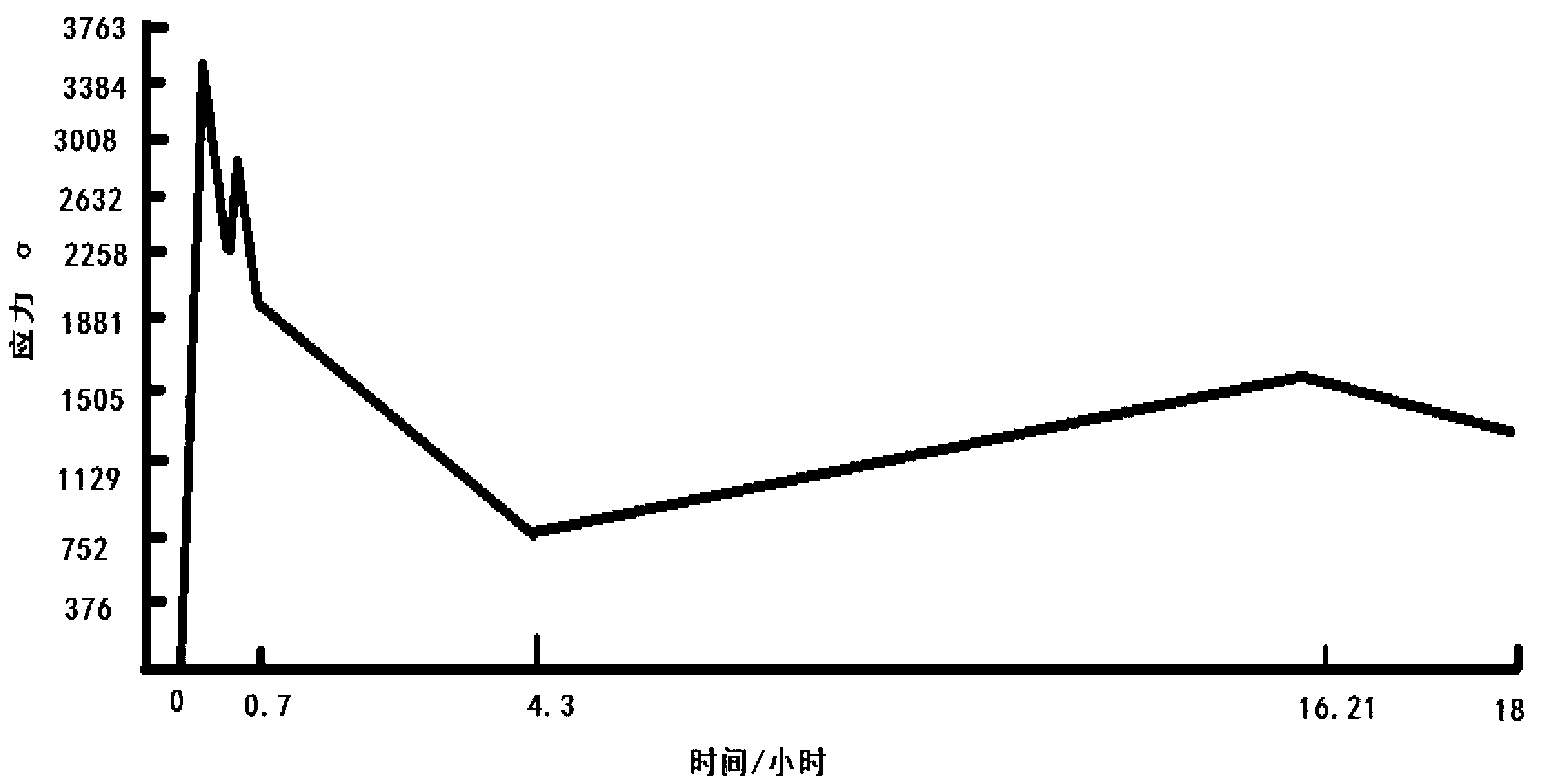

[0072] Following the technical scheme of the present invention, in the present embodiment, curing container 2 has a diameter of 30cm, length 40cm, and wall thickness 3.0cm; test tube 4 has a length of 15cm, a nozzle diameter of 2cm, and a tube wall thickness of 2m; temperature sensor 7 adopts an armored thermocouple ; Strain gauge 8 adopts 120Ω BB120-44A (11) 250 high temperature strain gauge; strain amplifier 10 adopts YE3818 dynamic strain gauge. In this example, the stress of a certain point in the explosive is measured during the curing process of 500ml cast PBX explosive, wherein the curing temperature is a constant temperature of 60°C, and the strain gauge adopts the half-bridge method, using two strain gauges, and one strain gauge is used as the strain gauge of the explosive Measurement, another strain gauge is used as a temperature compensation plate to eliminate the influence of temperature changes on the accuracy of strain measurement. Stick the strain gauges for str...

Embodiment 2

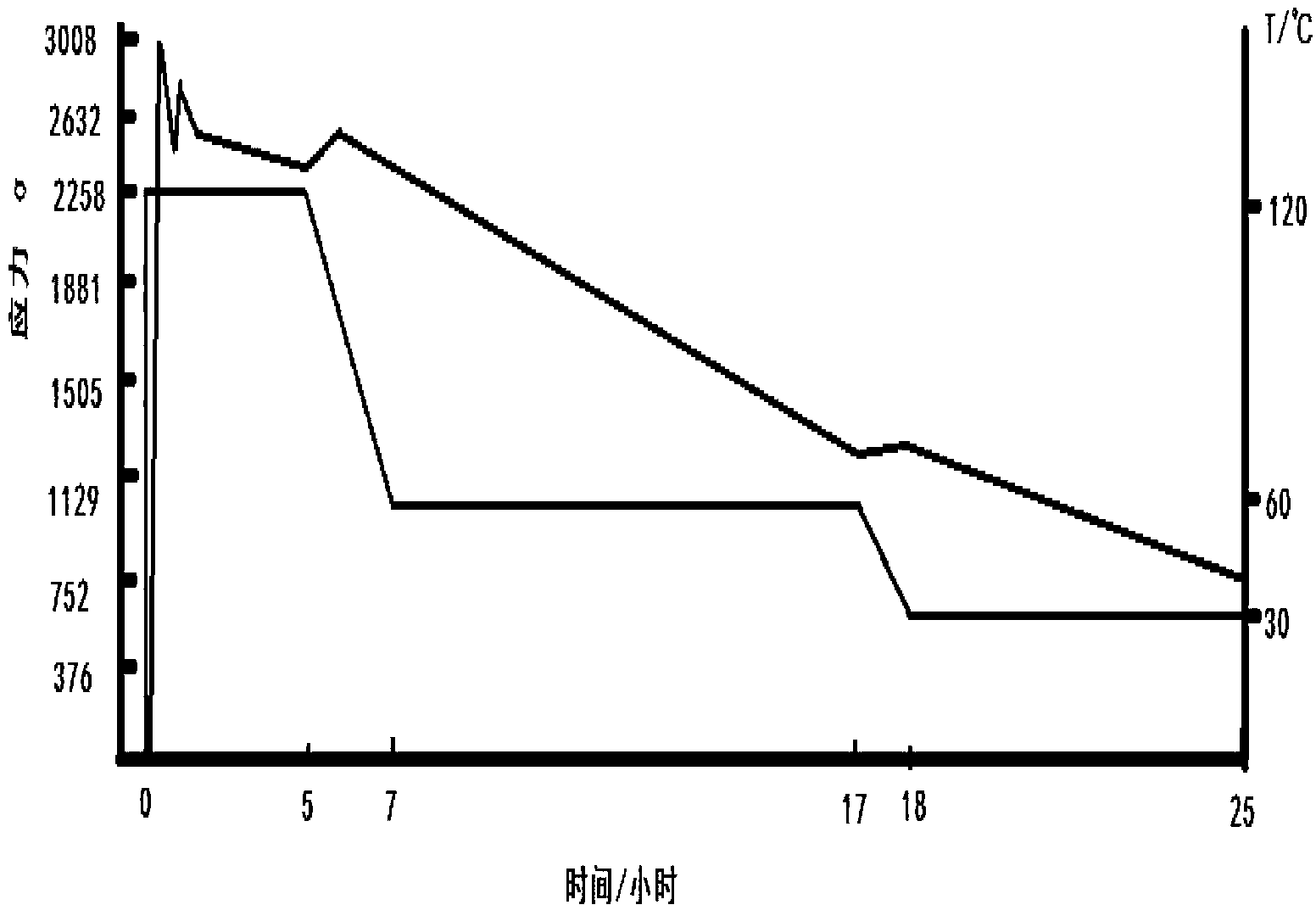

[0076] This embodiment provides the stress measurement at any point inside the explosive column in the same explosive solidification process as in Example 1. The measuring instruments and measurement methods used are exactly the same, and the difference is that the present embodiment adopts a temperature-variable curing method to carry out 500ml pouring PBX explosive solidify. The variable temperature curing method starts from 120°C for 5 hours at high temperature, then drops the temperature at 0.5°C / min to 60°C for 10 hours at a constant temperature, and then drops to 30°C at 0.5°C / min for 5 hours. The obtained stress-time curve and curing temperature-time curve of the curing process are as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com