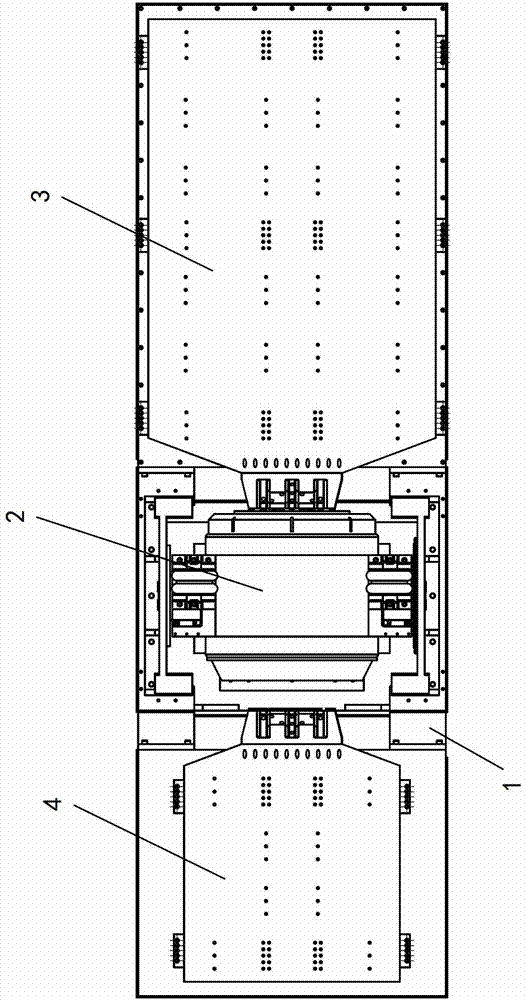

Assembled horizontal slide table

A horizontal sliding table, grouping technology, applied in the direction of measuring device, vibration test, machine/structural component test, etc., can solve the problems of low feasibility, time-consuming, cumbersome switching operation, etc., to achieve convenient operation and stable performance , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

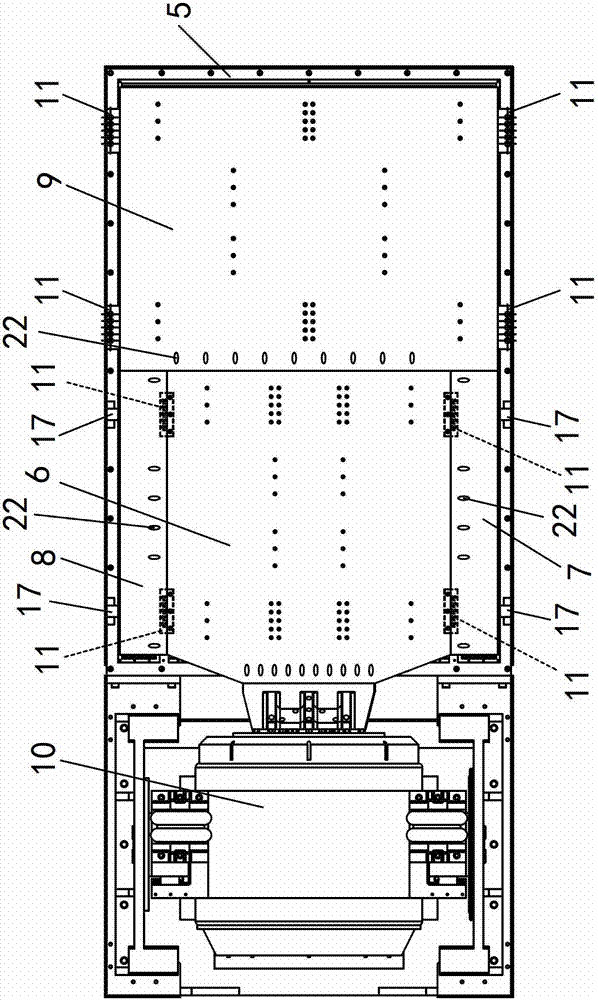

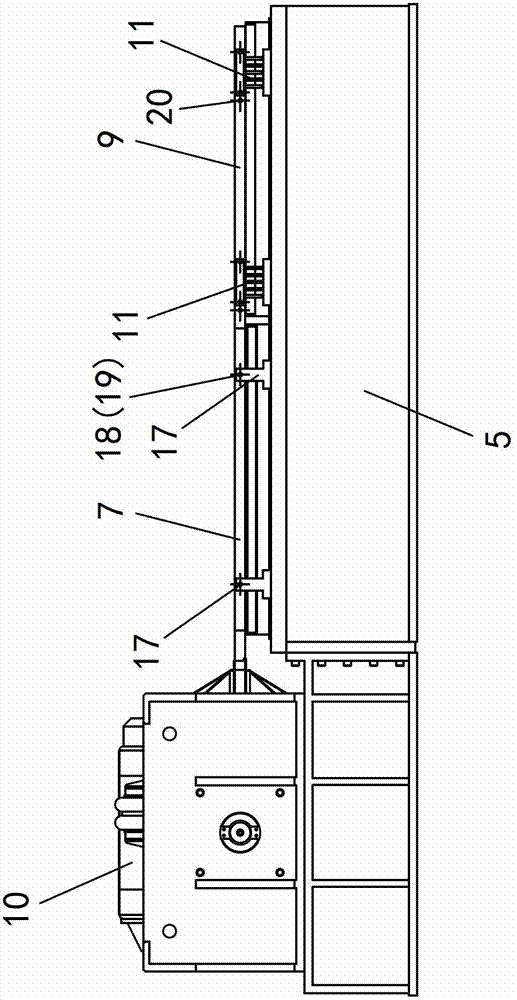

[0030] Example: see attached Figure 2-7 Shown:

[0031] A combined horizontal slide table, comprising a base 5 and a table top slidably arranged on the base 5, the table is composed of a front middle table 6, a front left side table 7, a front right side table 8 and a rear table 9 composition.

[0032] The front end of the front intermediate table 6 is rigidly connected to the moving coil of the electric vibrating table 10, and a guiding mechanism along the front and rear directions is provided between the front intermediate table 6 and the pedestal 5 . The left and right sides of the front middle table 6 are each provided with at least one neutral holding device 11, specifically as shown in the figure, two middle holding devices are respectively arranged on each of the left and right sides of the front middle table 6 11. figure 2 Among them, the neutral holding device 11 of the front middle table 6 is blocked by the edge of the front middle table 6, so figure 2 is mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com