Method and nozzle for suppressing the generation of iron-containing vapor

A nozzle, steam technology, applied in the direction of transportation and packaging, packaged food, packaged item types, etc., can solve the problems of limited available space, high installation cost, suction extraction equipment is not considered, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

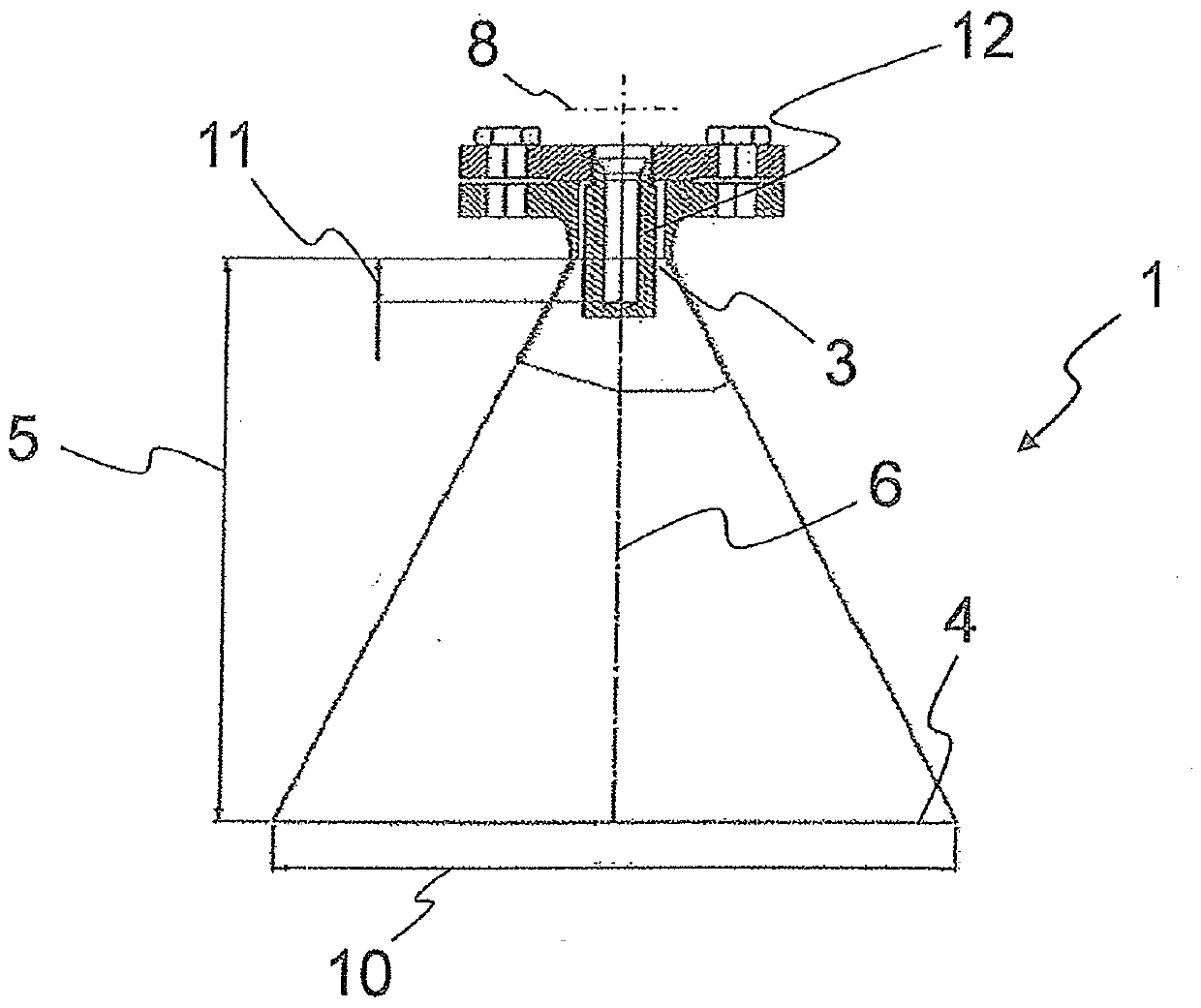

[0042] figure 1 A top view of a nozzle 1 according to the invention is shown. Nozzle 1 has a CO 2 (carbon dioxide) inlet 3 and outlet 4 which are spaced apart by a distance 5 in the direction along the outlet axis 6 . During operation, liquid CO 2 It can be supplied at the inlet 3 via the inlet area 11 . Likewise, in figure 1 The inlet 12 tapering towards the inlet region 11 is shown in . Furthermore, a transverse axis 8 is shown in which the nozzle 1 widens from the inlet 3 along the outlet axis 6 towards the outlet 4 in the direction of the transverse axis 8 until an outlet width 10 is reached.

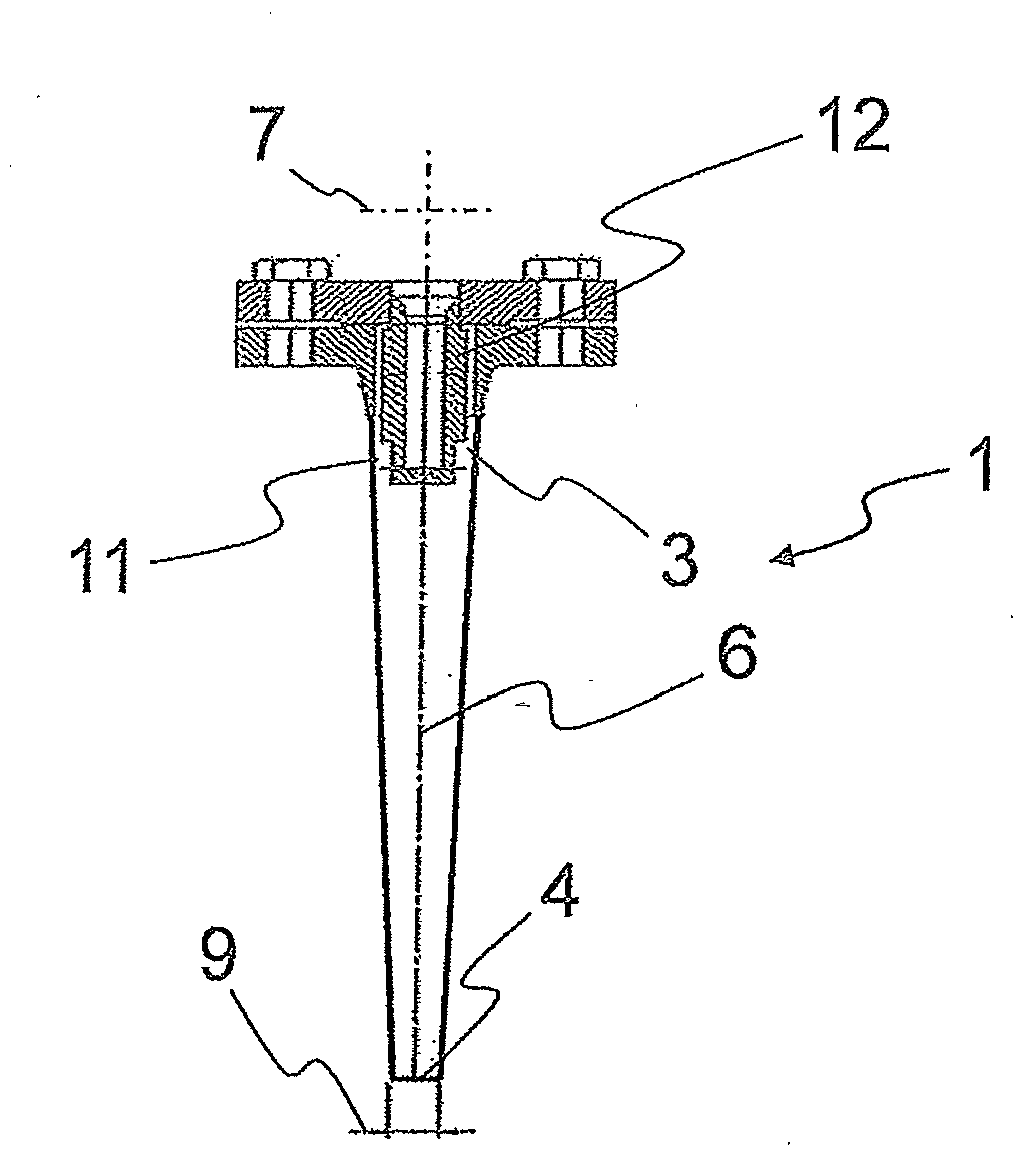

[0043] The nozzle 1 according to the invention is in figure 2 Shown in cross-section. The transition from the inlet 12 along the vertical axis 7 to the inlet region 11 at the inlet 3 can be seen in this view. Furthermore, it can be seen that the nozzle 1 tapers from the inlet 3 in the direction of the outlet axis 6 towards the outlet 4 in the direction of the vertical axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com