Initial position detection for a sensorless, brushless dc motor

A sensing circuit and phase technology, applied in starting devices, electronic commutators, etc., can solve problems such as unreliability, small size, unsuitable for direct application, and increased cost of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

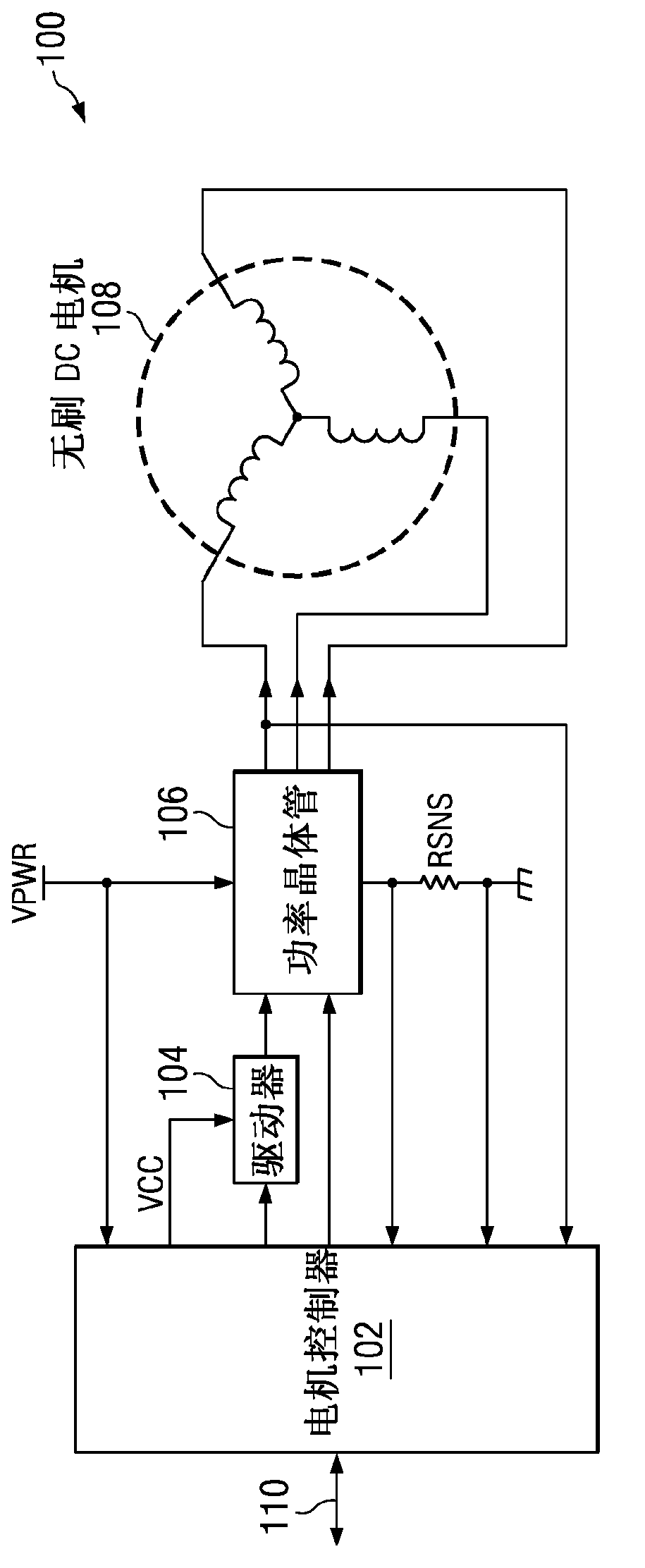

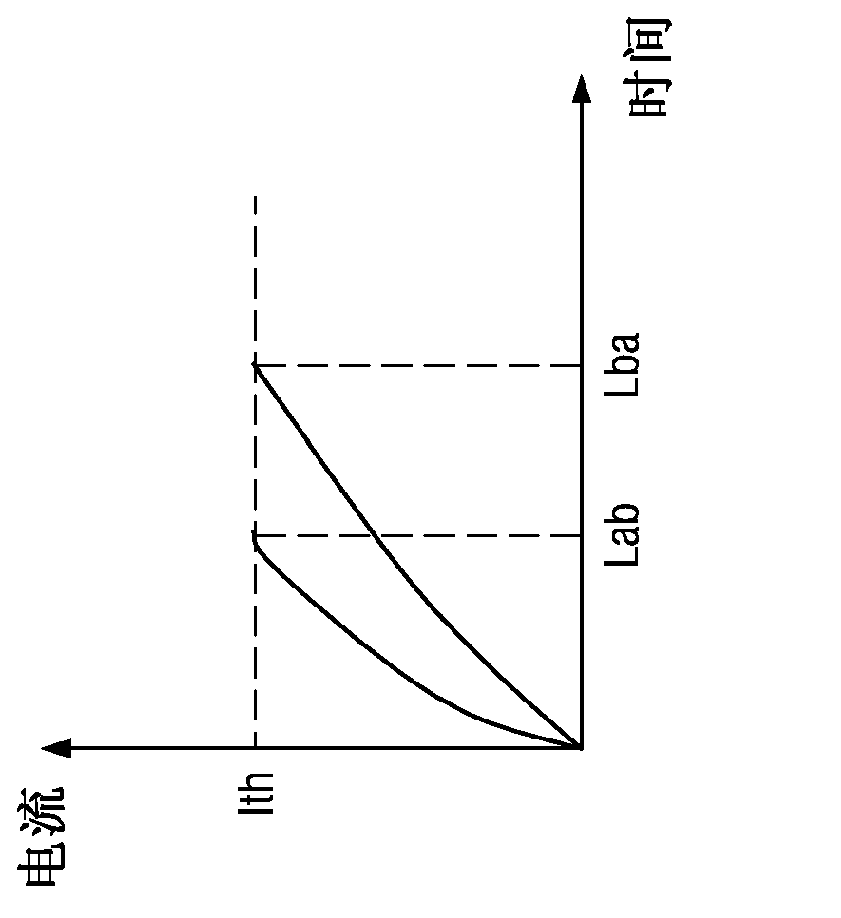

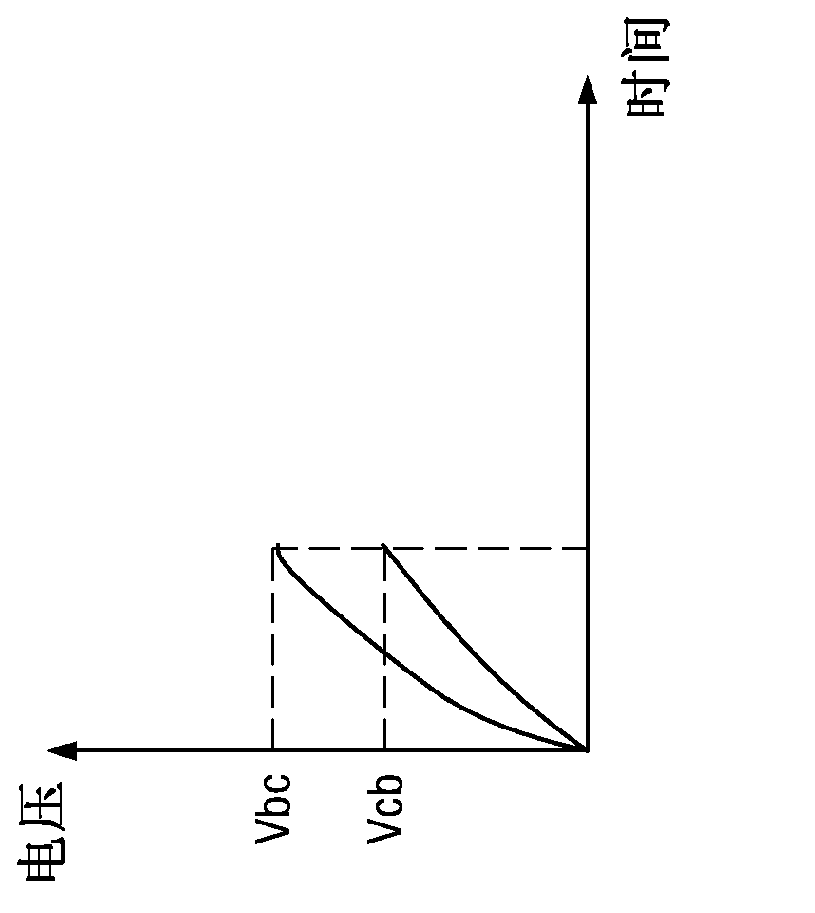

[0028] figure 1 An exemplary system 100 is shown. The system 100 generally includes a motor controller 102 , an actuation circuit (which may include a driver 104 , a power transistor 106 , and a sense resistor RSNS), and a sensorless brushless DC motor 108 . When determining the initial position of the motor 108, the motor controller 102 (which may control itself, or be programmed through a communication channel 110, which may use one or more communication architectures, such as inter-integrated circuit (I 2 C) bus or Universal Asynchronous Receiver / Transmitter (UART)) generates voltage pulses that engage each pair of phases of the motor 108 . The current traversing each pair of phases of the motor 108 can be sensed with a sense resistor RSNS (which may be, for example, 500 mΩ) and should be small enough to maintain an initial position large enough for detection (ie, about lasts about 1ms). Specifically, the motor controller 102 can measure the rise times of these currents...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com