Robot Assembly Fixture

A technology of manipulators and jigs, which is applied in the direction of manufacturing tools, metal processing, and metal processing equipment. It can solve problems such as incorrect insertion of needle-shaped plug-ins, potential safety hazards in products, and increased fatigue, achieving low cost and low labor intensity. , to avoid the effect of assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

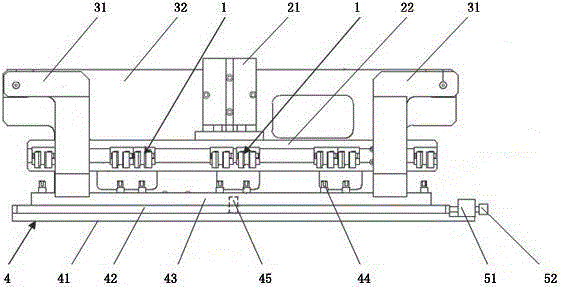

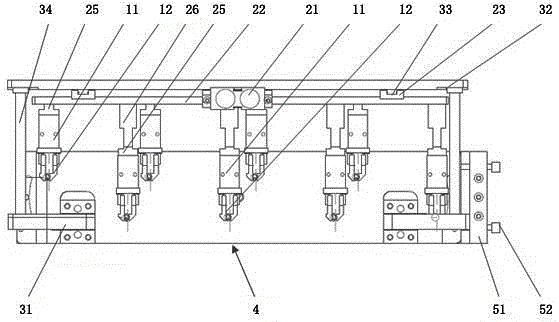

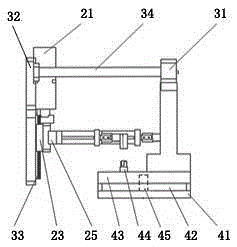

[0018] Such as Figure 1 to Figure 3 As shown, the manipulator assembly jig includes a manipulator device and a base 4. The base 4 is provided with several sets of positioning parts for fixing the parts to be processed. The number of groups of devices and manipulator devices is equal to the number of positioning parts. Each group of manipulator devices includes manipulators 1 equal to the number of plug-ins to be inserted into the parts to be processed. The fixed plate 22 is connected and driven by the lifting device 21 to move up and down. The lifting device 21 Supported on the base 4 by a support structure, the manipulator 1 includes a gripper 12 and a robot arm 11 , and the robot arm 11 drives the gripper 12 to perform back and forth telescopic movements.

[0019] The support structure includes a support plate 32 and a support frame 31. The lifting device 21 is fixed on the support plate 32. The support frame 31 is fixed on both lateral sides of the base 4 and is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com