Blank material table for high-speed notching machine

A high-speed punching and blanking technology, used in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of monotonous machinery, harsh working environment, poor safety, etc., and achieve the effect of ensuring smooth grasping and ingenious structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] See attached picture.

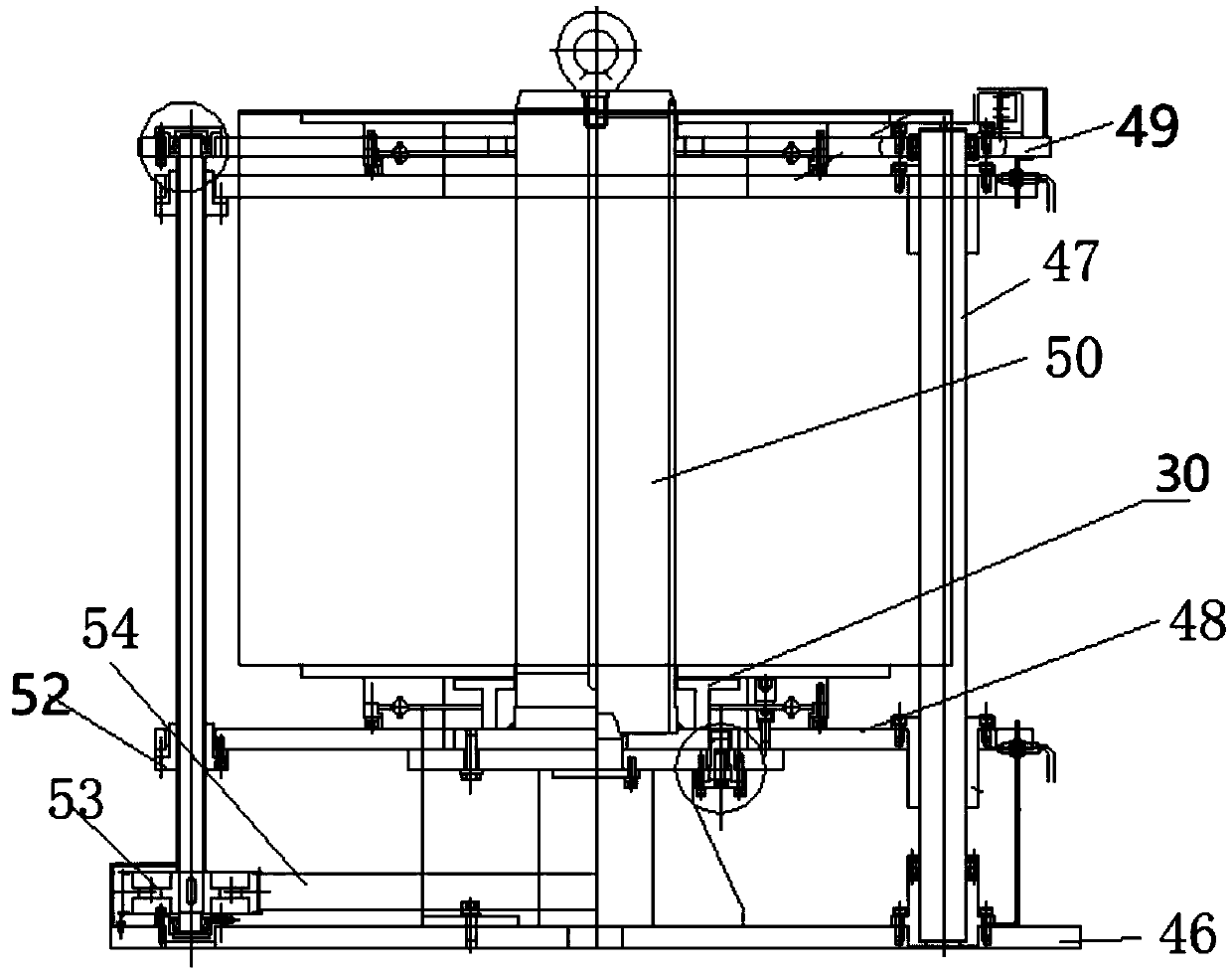

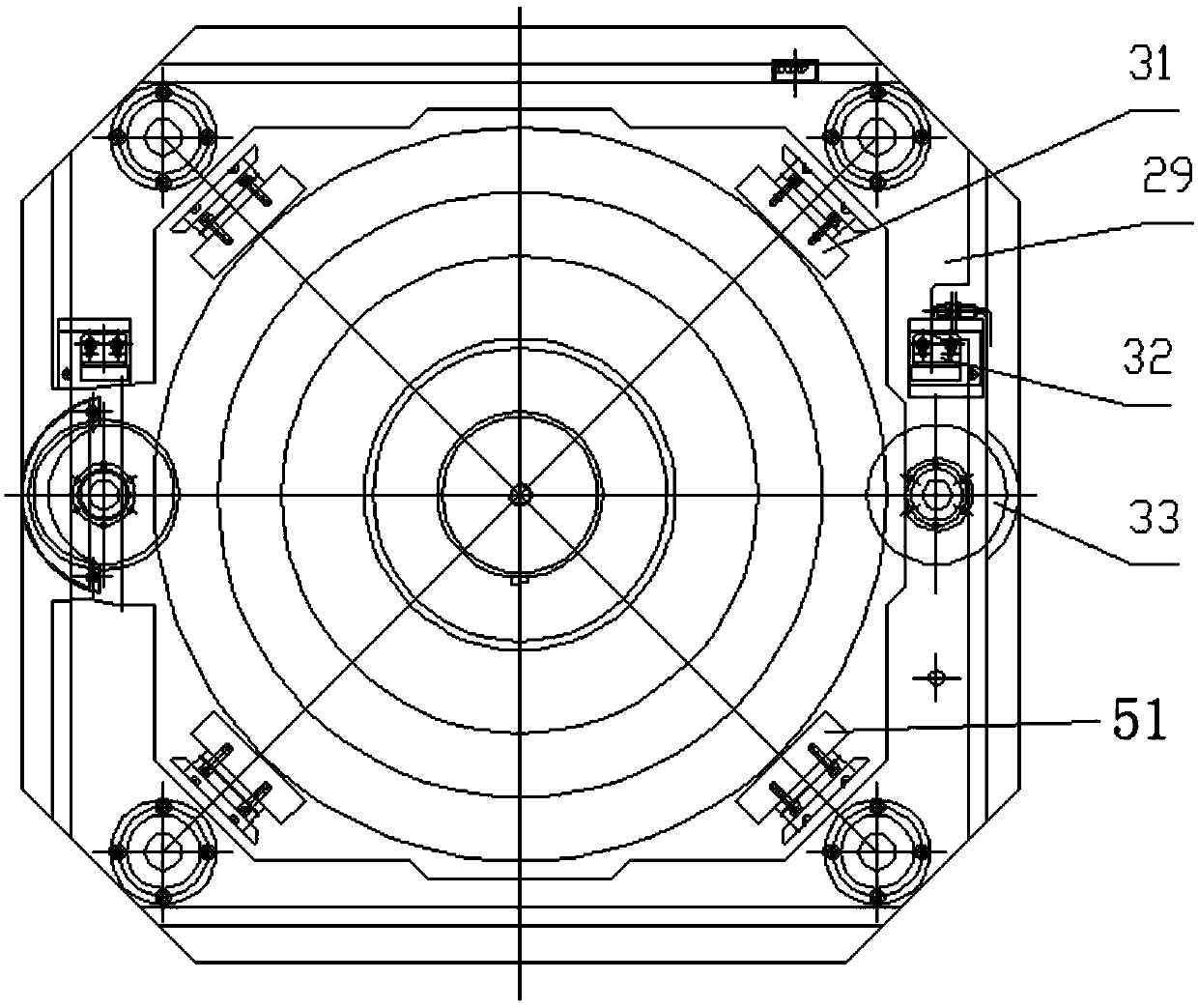

[0017] A rough material platform for high-speed notching machine is composed of a material stack installation and positioning mechanism 30, a motor blank sheet spreader 31, a blank material stack height sensor 32, and a blank material table lifting system 33.

[0018] The blank material platform includes a blank material platform bottom plate 46, four corners of the blank material platform bottom plate 46 are respectively fixed with a blank material platform column 47, and a blank material platform movable plate 48 that can move up and down is movable on the blank material platform column 47. A frame-shaped blank table top plate 49 is fixed on the top of the blank table column 47; a longitudinal blank positioning column 50 is fixed in the center of the blank table bottom plate, and the top of the blank positioning column 50 passes through the blank table movable plate 48 and extends to the blank The central part of the top plate 49 of the blank t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com