Method for automatically assembling nozzle bottle cap

A technology for automatic assembly and bottle caps, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, large labor force, and low production efficiency, and achieve the effect of improving processing efficiency and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

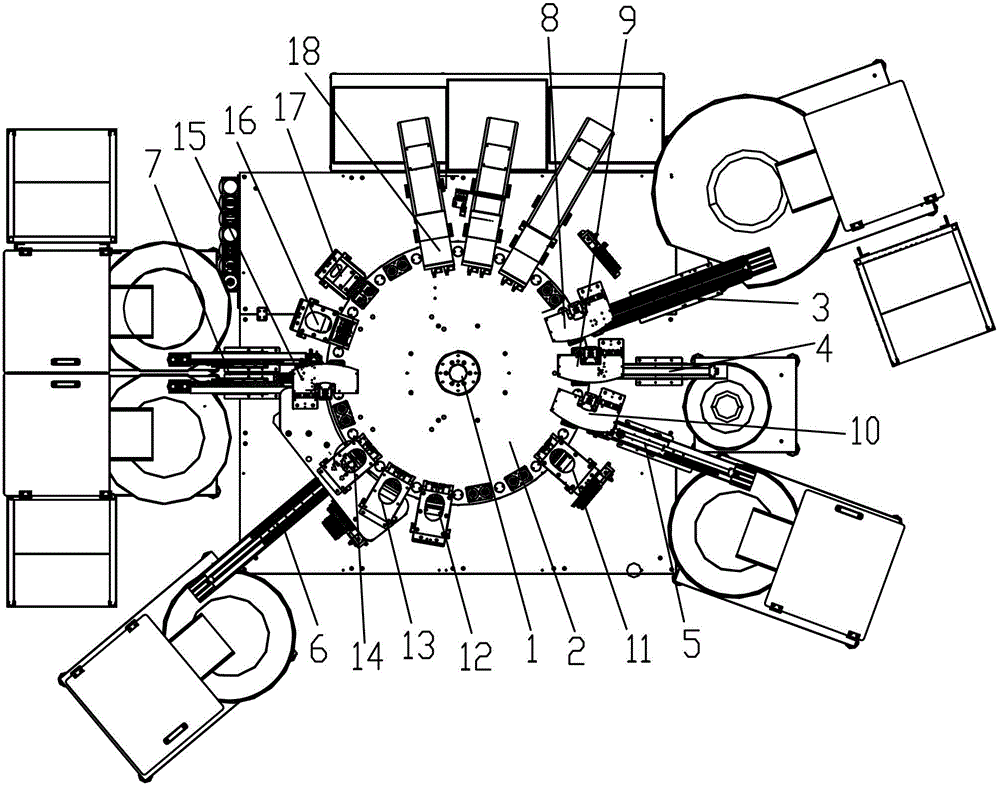

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0021] see figure 1 , the embodiment of the present invention includes:

[0022] A method for automatic assembly of nozzle bottle caps, comprising: the first step, the cam grab mechanism 8 puts the bottle cap base shell sent by the bottle cap base shell automatic feeding mechanism 3 into the positioning fixture, and the sensor detects the presence of the base shell , the station cam indexer 1 drives the station index disc 2 to the next station; in the second step, the valve core pick-and-place positioning mechanism 9 puts the valve core delivered by the valve core automatic feeding mechanism 4 into the positioning jig In the base shell, the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com