Sand blasting apparatus for small diameter pipe fitting inner walls

A small-diameter tube and sandblasting device technology, applied in abrasive feeding device, used abrasive processing device, abrasive jetting machine tool, etc. Sand treatment and other issues, to achieve the effect of being conducive to pressure holding and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the drawings and embodiments:

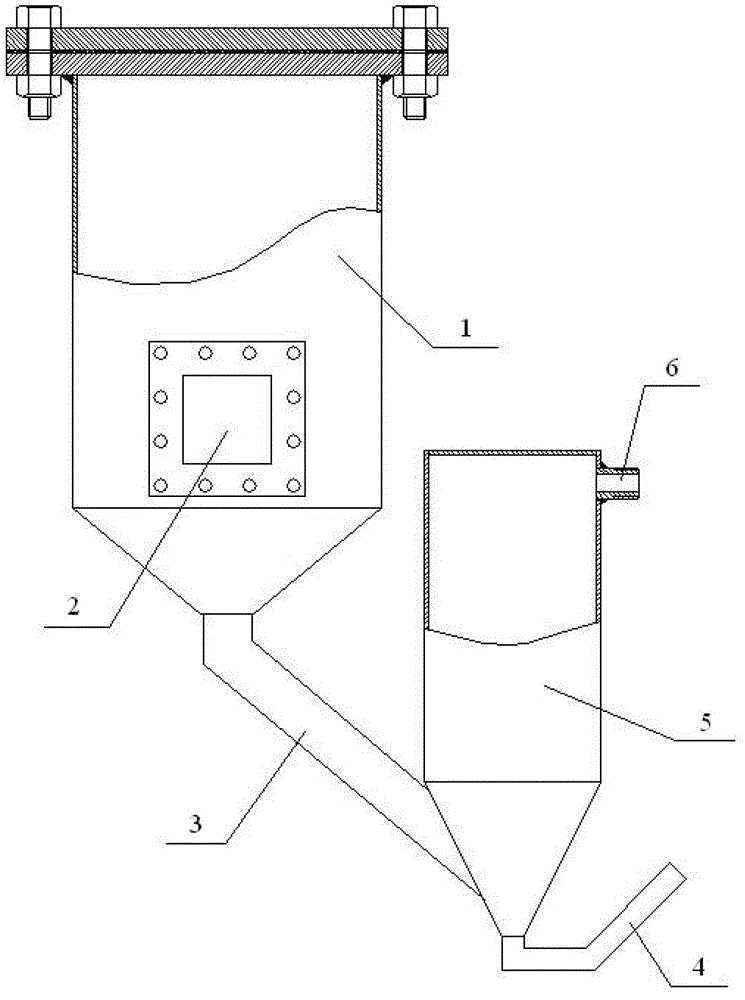

[0018] Sandblasting device for the inner wall of small diameter pipes, such as figure 1 As shown, the sand storage box 1, the sand mixing box 5 and the sand outlet pipe 6 are included. The sand storage box 1 is used for storing abrasives, and the sand mixing box 5 is used for sand mixing.

[0019] During use of this embodiment, the pressure in the sand storage tank is set to 0.7 MPa. The top end of the sand storage box 1 is connected with an end cover for sealing the sand storage box 1 and keep the pressure in the sand storage box 1 stable. The end cap is divided into three layers: the top layer, the middle spacer layer and the bottom layer. The intermediate layer is composed of rubber, and other pressure-resistant sealing materials can also be used. The top layer corresponds to the shape of the middle spacer layer; the shape of the bottom layer also correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com