Universal adjustable sand blasting clamp

An adjustable and universal technology, which is applied in the direction of used abrasive processing devices, manufacturing tools, abrasives, etc., can solve the problems of surface treatment hangers and fixtures that cannot meet the requirements, low defect rate, and lack of versatility. , to achieve the effect of reducing product scrap rate, saving time and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

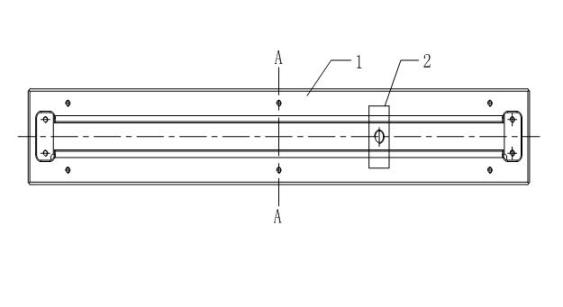

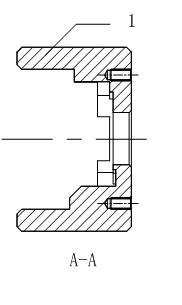

[0012] Such as figure 1 , figure 2 As shown, the universal adjustable sandblasting fixture includes a fixture base 1. The fixture base 1 is made of bakelite material. There is a rectangular groove on the fixture base 1, and the long sides of the rectangular groove at both ends are arranged in a downward stepped manner with equal heights. The stepped rectangular trough is divided into an upper step, a middle step and a lower step. The lower steps on the long sides of the two ends of the rectangular trough touch each other. A reinforced protective body is installed on the upper step and the middle step, and a movable adjustment is set on the upper step. device 2.

[0013] The rectangular groove is set in a stepped manner. When the product is sandblasting, the excess sand is blocked from spraying to other parts of the product that should not be sprayed, so as to prevent product damage and reduce product scrap rate. At the same time, the movable adjustment device 2 can effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com