Clamp with linear motor

A technology of linear motors and fixtures, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems that linear motors do not have continuous output and cannot continuously provide clamping force, etc., and achieve compact structure, reliable self-locking pressurization, and increased strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be further described in detail below.

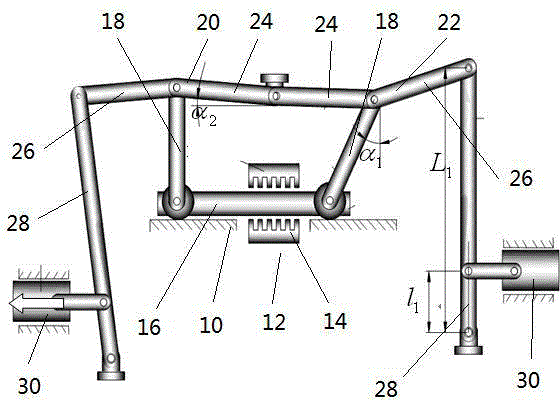

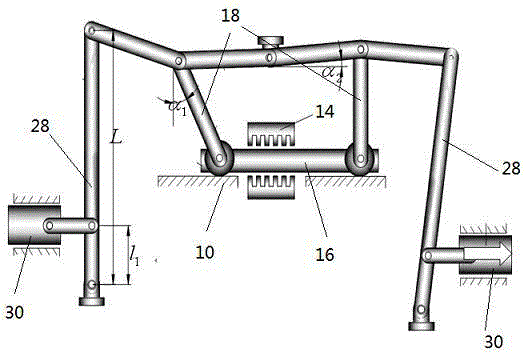

[0018] Such as figure 1 and figure 2 As shown, a fixture based on a linear motor of the present invention includes a machine base 10 on which a double-sided linear motor 12 is arranged. The linear motor 12 includes a primary 14 and a secondary 16 .

[0019] Both ends of the secondary 16 are respectively connected to a connecting rod 18 , and each connecting rod 18 is connected to a toggle mechanism 20 , 22 . The toggle mechanism 20 includes a pivotally connected first joint arm 24 and a second joint arm 26 , and the connecting rod 18 is pivotally connected to the connection point of the first joint arm 24 and the second joint arm 26 . The first joint arms 24 of the two toggle mechanisms 20 are pivotally fixed on the same point of the machine table 10 . A booster lever 28 is pivotally arranged on the machine table 10, and the free end of the second section arm 26 is pivotally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com