Adjustable large package bag-type robot gripper

A technology of robot grippers and large packaging bags, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as inability to realize production line processing, and achieve reliable performance, efficient grasping operations, and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

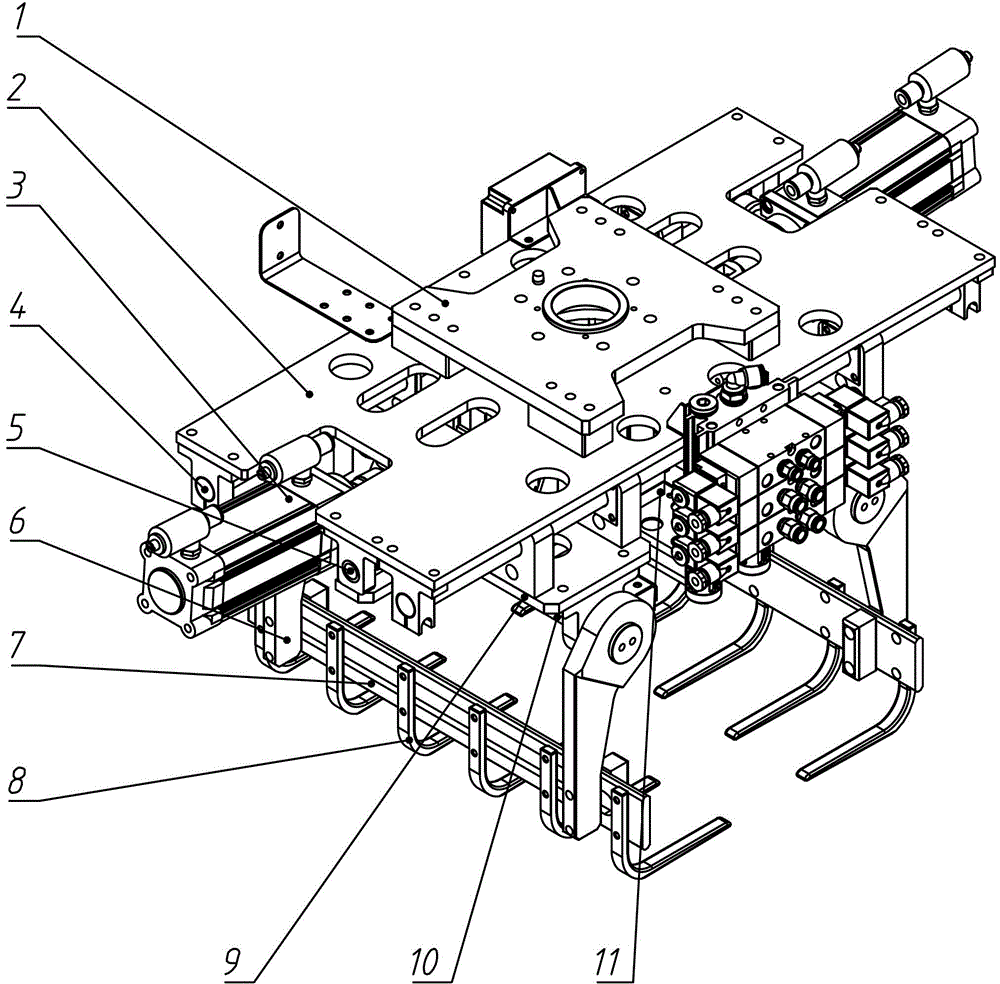

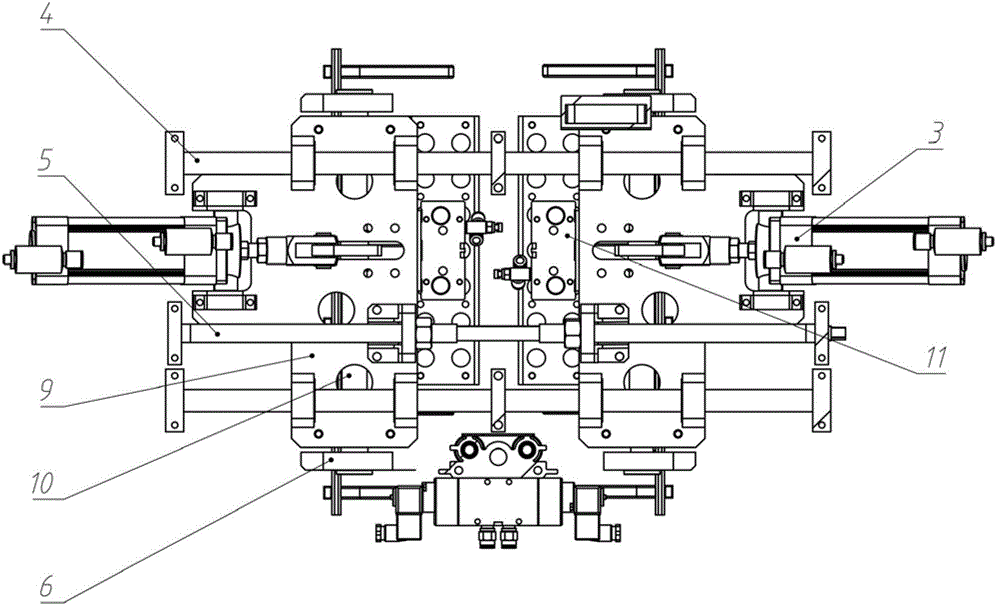

[0014] The adjustable large bag type robot grip provided by the present invention, such as figure 1 , figure 2 As shown, it includes: flange 1, base plate 2, clamping cylinder 3, guide shaft 4, screw rod 5, connecting arm 6, clamping jaw connecting plate 7, clamping jaw 8, mounting plate 9, rotating shaft 10 and pressing cylinder 11.

[0015] A flange 1 is installed above the base plate 2, and the entire robot gripper is installed on the robot arm through the flange 1. A lead screw 5 and a guide shaft 4 arranged parallel to each other are horizontally connected under the base plate 2 , and the lead screw 5 and guide shaft 4 are all passed through the mounting plates 9 on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com