Roller for paper machining machine

A processing machine and roller technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of slippage, increase of production cost, material running out, etc., and achieve the effects of avoiding material running out, improving wear resistance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

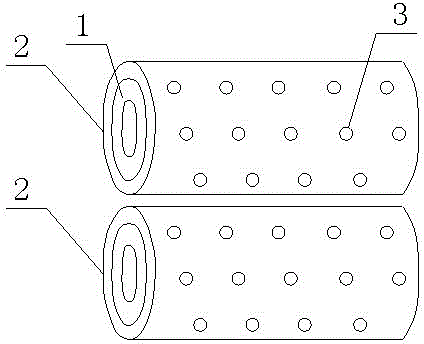

[0014] see figure 1 , figure 1 It is a structural schematic diagram of the present invention.

[0015] The drum used on paper processing machines includes an upper drum and a lower drum, and the upper and lower drums are rolled from seamless steel pipes; there is an outer tube 1 on the upper drum, and the outer surface of the outer tube 1 is A composite layer 2 is provided, and a composite layer 2 is also provided on the lower roller. The composite layer 2 contains silicon carbide or corundum, which is used to reduce wear and improve wear resistance;

[0016] The upper drum and the lower drum ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com