Seed cotton deslagging electric screen

A technology of electric sieve and seed cotton, which is applied in the direction of fiber opening and cleaning machines, can solve the problems of mechanical vibration sensitivity, wear, mechanical fatigue, etc., and achieve the effect of reducing mechanical connections and working reliably and stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

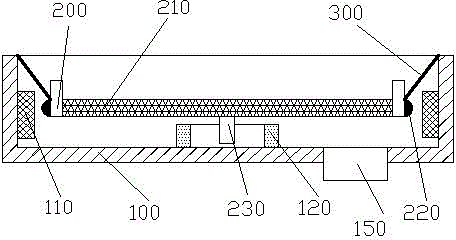

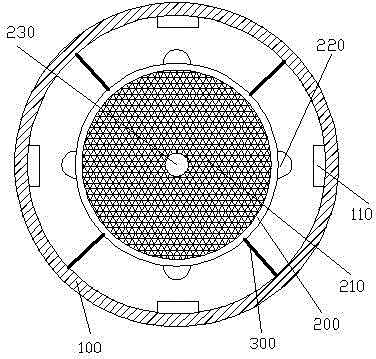

[0017] refer to figure 1 and figure 2 , in this embodiment, the electric sieve for seed cotton slag removal includes a frame body 200 and a screen 210 arranged on the frame body 200, and the frame body 200 is horizontally arranged in an impurity box body 100 with an open upper end, so The frame body 200 is hinged to the trash box body 100 through at least three elastic connectors 300, at least two permanent magnets 220 are evenly distributed on the outer periphery of the frame body 200, and the inner walls of the trash box body 100 are respectively provided with There are electromagnets 110 adapted to the permanent magnets 220, and the electromagnets 110 are respectively established with an independent electrical connection with a power controller.

[0018] In the aforementioned electric sieve for seed cotton slag removal, the bottom of the screen 210 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com