Dual-core jean fabric

A denim fabric, inner and outer double-layer technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of poor elasticity and poor recovery, and achieve the effect of high elasticity, improved product performance, and good recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

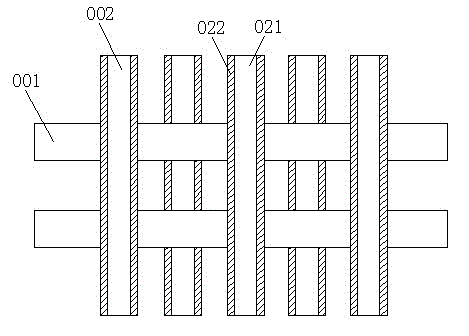

[0010] A double-core denim fabric, comprising interlaced weaving of warp yarn 001 and weft yarn 002, the weft yarn 002 is an inner and outer double-layer yarn, the inner layer 021 is T400 cotton yarn, and the outer layer 022 is Lycra wrapped on the inner layer 021. The warp yarn 001 is sello spinning and / or cotton yarn.

[0011] The warp yarn 001 has a yarn density of 250-300 per inch, and the weft yarn 002 has a yarn density of 100-120 per inch. The fineness of the warp yarn 001 is 20-40D.

[0012] The present invention provides a kind of train of thought and method, and there are many methods and approaches for realizing the technical solution. The above description is only a preferred embodiment of the present invention. It should be pointed out that for those of ordinary skill in the art, without Under the premise of the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications should also be regarde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com