High-frequency tuning mass damper

A technology for tuning mass and shock absorber, which is applied in building components, shockproof and other directions, can solve the problem that tuned mass shock absorber is difficult to apply to high-frequency vibration above 15Hz, and achieves superior cost performance, broad market application prospects, and compact space structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

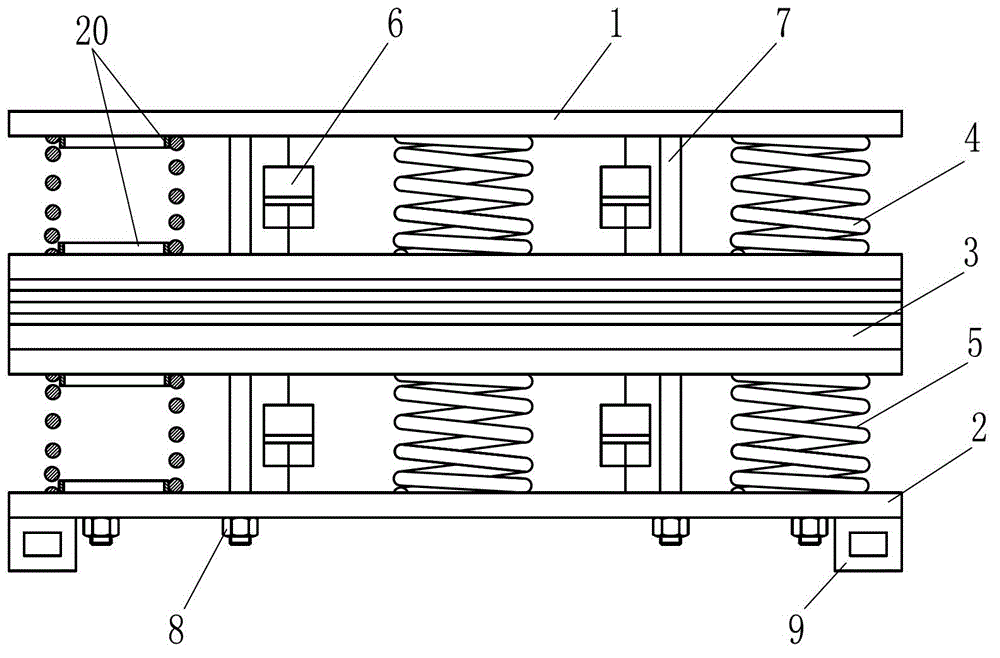

[0035] Such as image 3 with Figure 4 The high-frequency mass-tuned shock absorber of the present invention shown includes a connecting plate 2, an elastic element, a damping element 6, and a mass block 3. In addition, it also includes a pre-tightening connecting piece 1, and the connecting plate 2 and the pre-tightening connecting piece 1 are arranged Preload structure 7. Among them, the pre-tightening connector 1 is made of steel plate, the size is the same as that of the connecting plate 2, and the mass block 3 is arranged between the connecting plate 2 and the pre-tightening connector 1; Set between the mass block 3 and the pre-tightening connector 1, the spiral steel spring 5 is set between the mass block 3 and the connecting plate 2; Between the block 3 and the pre-tightening connector 1 and between the mass block 3 and the connecting plate 2 . In addition, in this example, the pre-tightening structure 7 is set between the connecting plate 2 and the pre-tightening co...

Embodiment 2

[0041] Such as Figure 5 with Image 6 The difference between the high-frequency mass-tuned shock absorber of the present invention shown in Embodiment 1 is that the damping element 6 is only arranged between the mass block 3 and the connecting plate 2, and includes two small-hole throttling dampers. In addition, in the pre-tightening structure 7, the two ends of each pre-tightening connecting rod are respectively provided with thread structures, and the pre-tightening connecting rods are arranged through the pre-tightening connecting piece 1 and the connecting plate 2, and the nut 8 is used to cooperate with the threaded structure to lock the pre-tightening rod. The relative position of tight connector 1 and connecting plate 2. In order to prevent the elastic element from sliding horizontally during use, the pre-tightening connector 1, the connecting plate 2, and the mass block 3 adjacent to the elastic element are respectively fixed with limit seats 23, and the outer surfac...

Embodiment 3

[0044] Such as Figure 7 with Figure 8 The difference between the high-frequency mass-tuned shock absorber of the present invention shown in Embodiment 2 is that the damping element 10 is only arranged between the mass block 3 and the pre-tightening connector 1 , specifically two viscous dampers. In addition, one end of the pre-tightening connecting rod 7 is provided with a threaded structure, and the other end is welded and fixed on the connecting plate 2, and one end of the pre-tightening connecting rod with a threaded structure is set through the pre-tightening connector 1, and the nut 8 is used to cooperate with the threaded structure. The relative position of the pre-tightening connector 1 and the connecting plate 2 is locked, and the pre-tightening link 7 passes through the cavity in the middle of the elastic element, that is, passes through the cavity in the middle of the upper and lower corresponding helical steel springs 4 and 5 .

[0045] Compared with the first em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com