A method for on-line monitoring of full-field three-dimensional deformation of wind turbine blades under working conditions

A technology for wind rotor blades and working conditions, which is applied in the field of three-dimensional deformation measurement of the entire structure, which can solve the problems of sensor damage and failure, failure to fully reflect the displacement and strain of wind rotor blades, and limited range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

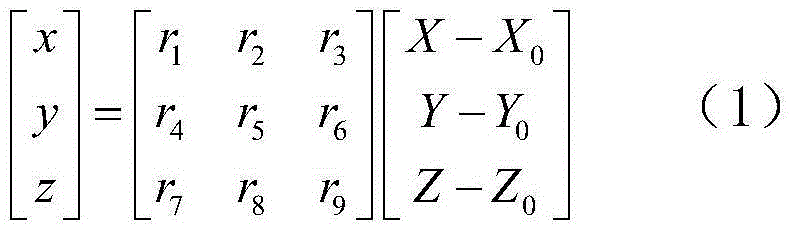

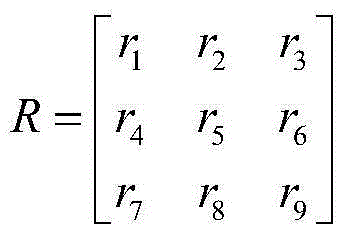

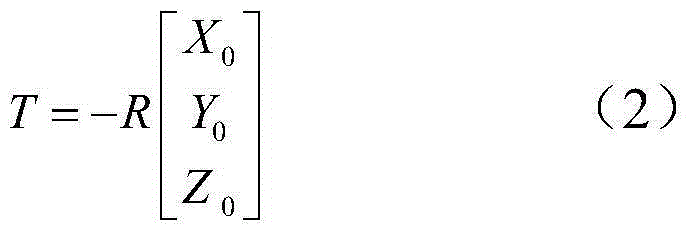

[0019] The invention provides an online monitoring method for three-dimensional deformation of a wind turbine blade in a working state, which includes the following steps:

[0020] (1) Spray paint on the surface of the wind rotor blade to be tested to form random speckles; the color contrast of the two paints is required to be high, and black and white matt paint is generally used, of course, other paints are also acceptable.

[0021] (2) Select the center of the hub of the wind turbine as the fixed mark point, and select another mark point at the root of each blade (where the stiffness is relatively high). The mark point at the root of each blade adopts a mark of a different shape, for example, three blades Use circles, triangles, squares, etc. respectively;

[0022] (3) Select two suitable positions in front of the wind rotor blades to set up two industrial digital cameras. In order to measure the three-dimensional displacement, the straight line from the two positions to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com