Rotational speed estimation method and device based on gear meshing vibration

A speed estimation and gear technology, applied in the field of signal processing, can solve problems such as poor accuracy and weak anti-noise ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

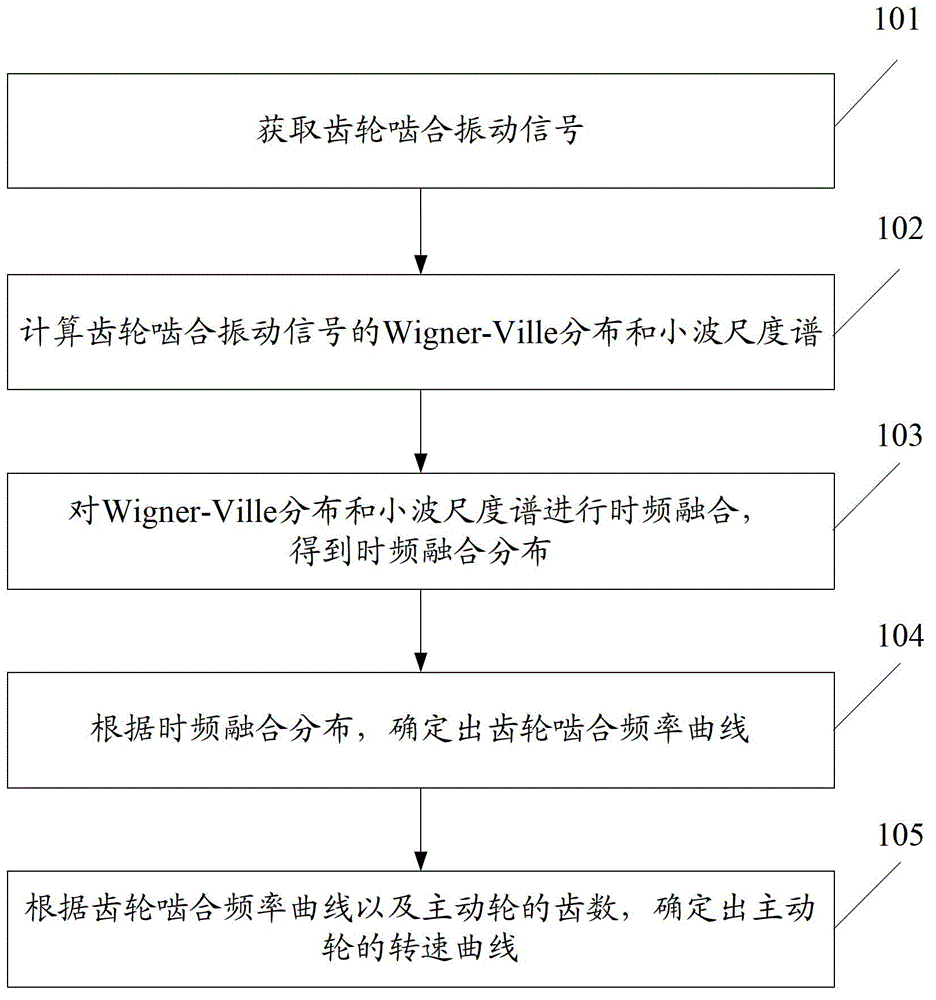

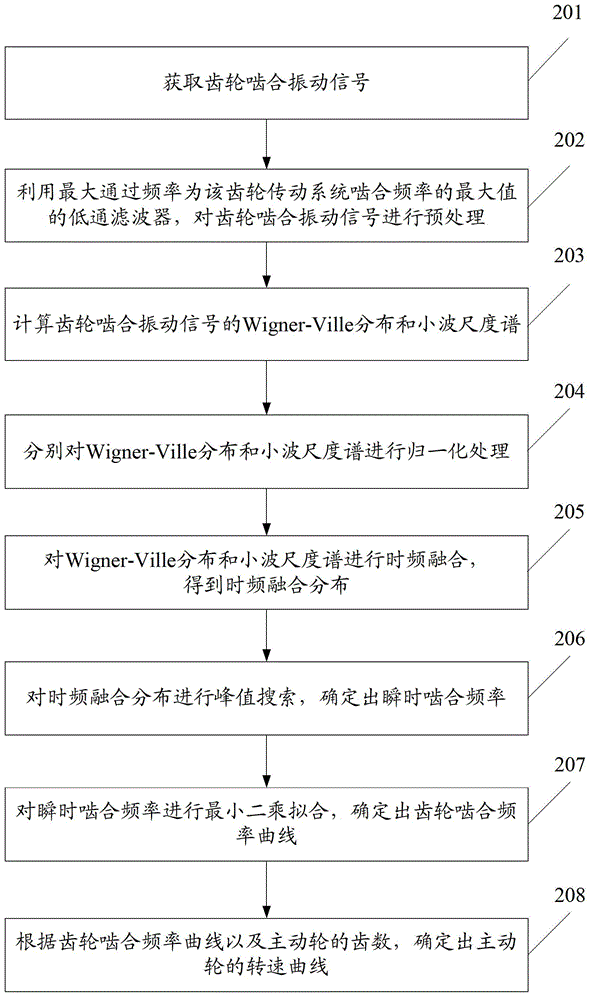

Method used

Image

Examples

Embodiment 1

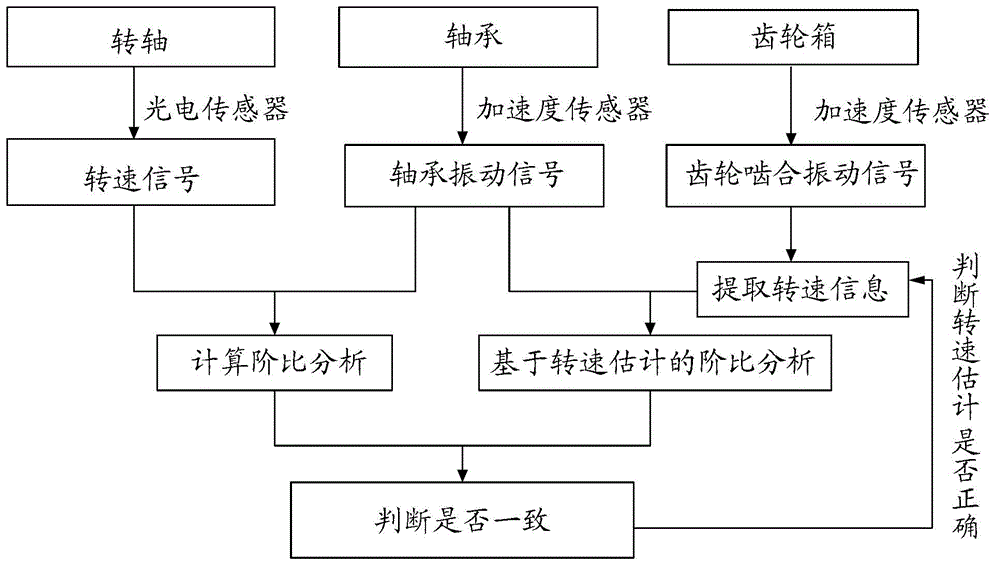

[0105] Embodiment 1: Application in fault feature detection of bearing outer ring;

[0106] When there are local damages or defects in the bearing, a sudden attenuation impact pulse force will be generated during the loading process, which will excite the high-frequency natural vibration of the bearing. This high-frequency natural vibration acts as the carrier wave of bearing vibration, and its amplitude will be modulated by the pulse excitation force caused by these defects, so that the final vibration waveform of the bearing will appear as a complex amplitude modulation wave, so it is necessary to use the envelope solution The vibration signal of the bearing is tuned to obtain the characteristic frequency of the modulation component.

[0107] The bearing fault vibration signal under variable speed is unsteady, and the envelope demodulation analysis will fail to detect the fault characteristics because of the frequency ambiguity on the envelope demodulation spectrum. Every t...

Embodiment 2

[0113] Embodiment 2: application in gear fault feature detection;

[0114] When the gear breaks, the natural vibration of the gear teeth will be excited when the broken teeth enter into mesh. This excitation will appear once every time the gear rotates, and it will appear on the frequency spectrum near the natural frequency of the gear. The side frequency band, and the bandwidth of the side frequency band is equal to the rotation frequency of the driving wheel.

[0115]The gear meshing vibration signal under variable speed is unsteady, and the order ratio analysis method is used to diagnose the fault of the gear meshing vibration signal, and the method described in the embodiment of the present invention is used to extract the speed information from the gear meshing vibration signal, and based on the speed information, in turn The gear meshing vibration signal is resampled at equal angles, and the order ratio analysis is carried out, so as to realize the fault diagnosis. In o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com