Time-spectrum analysis process method of ultrasonic testing material of coarse crystalline

A technology of time-frequency analysis and ultrasonic testing, applied in the use of sound wave/ultrasonic wave/infrasonic wave to analyze solids, electrical digital data processing, special data processing applications, etc. Amplification ability, signal distortion and other problems, to achieve the effect of easy understanding and judgment, Q value optimization, high time-frequency resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

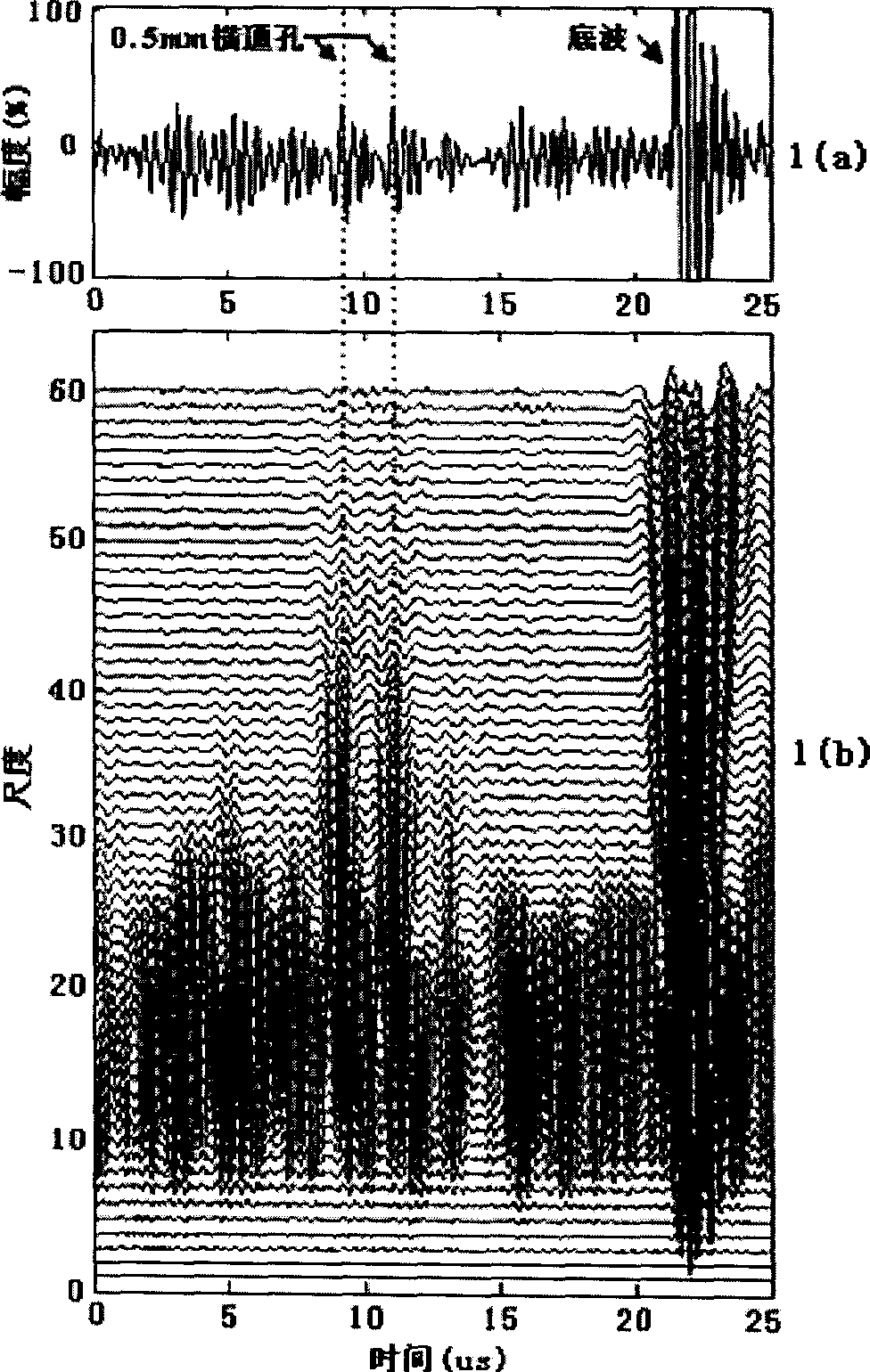

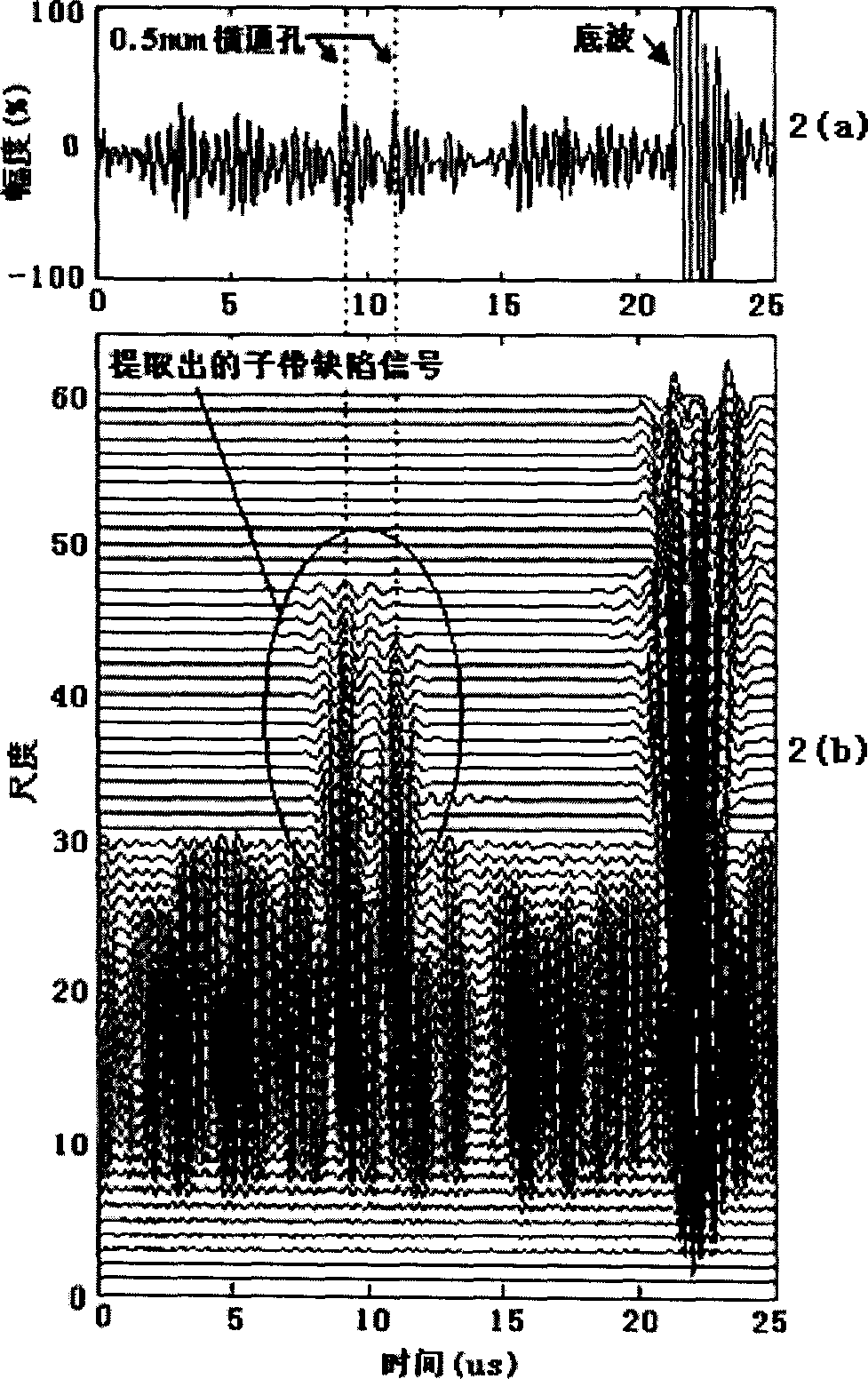

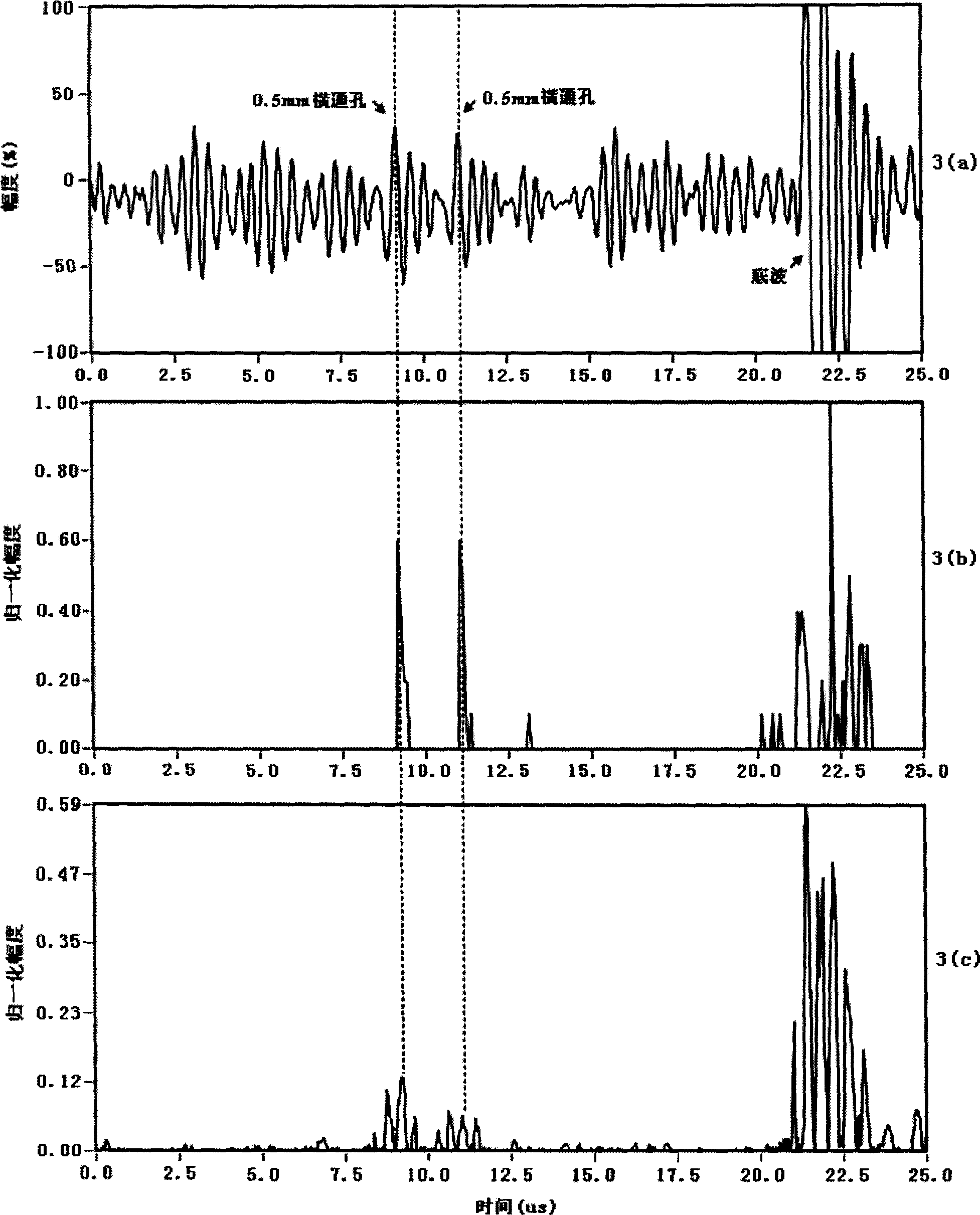

[0023] The detection object used in the accompanying drawings is coarse-grained austenitic stainless steel (grade OCr18Ni9Ti), and the traditional separation spectrum technology cannot detect the two φ0.5mm horizontal through-hole defects contained in it with a distance of 5mm. .

[0024] Press " three-step method " principle of the present invention, concrete implementation process is as follows:

[0025] Step 1: Obtain high-quality time-frequency images.

[0026] The time-frequency decomposition of the ultrasonic reflection signal x(t) of the coarse-grained material is performed by continuous wavelet transform:

[0027] WT ( τ , a ) = ∫ - ∞ + ∞ x ( t ) 1 a φ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com