Technical quality parameter tracking system of PROTOS cigarette making machine

A quality parameter and tracking system technology, applied in the field of process quality parameter tracking system, can solve the problems of unable to monitor, alarm, analyze and track process quality parameters of PROTOS cigarette machines, and achieve the effect of improving data integrity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

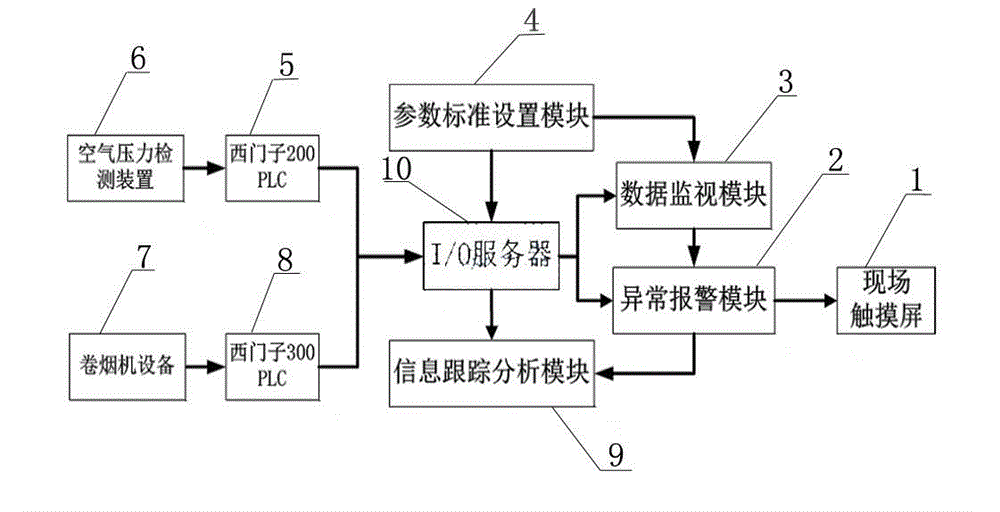

[0020] Attached below figure 1 The preferred embodiment of the present invention will be described in detail.

[0021] Such as figure 1 A PROTOS cigarette maker process quality parameter tracking system shown includes air pressure detection device 6, Siemens 200PLC5, cigarette maker equipment 7, Siemens 300PLC8, I / O server 10, parameter standard setting module 4, data monitoring module 3, and abnormal Alarm module 2, on-site touch screen 1, information tracking analysis module 9.

[0022] The air pressure detecting device 6 detects the air pressure data of the PROTOS cigarette machine in real time;

[0023] The Siemens 200PLC5 collects the air pressure data detected by the air pressure detection device 6 in real time, and transmits the data to the I / O server 10 through the industrial Ethernet.

[0024] The Siemens 300PLC8 collects the process quality parameter operation data detected by the cigarette maker equipment 7 in real time, and transmits the data to the I / O server 10 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com