Weighing-type transformer oil conservator

A transformer oil tank and oil conservator technology, applied in the direction of transformer/inductor cooling, etc., can solve problems such as accidents, oil level gauge indication errors, and oil level gauge misindications, etc., to achieve the effect of ensuring long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

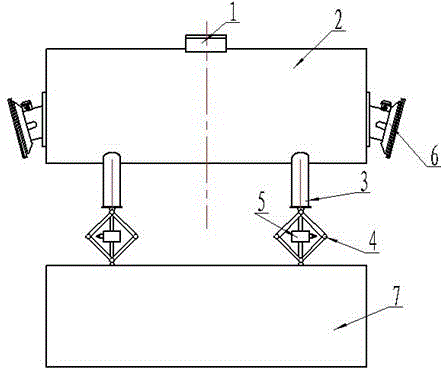

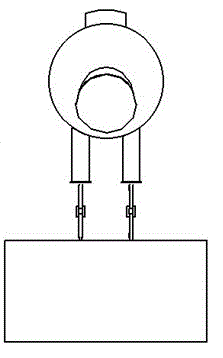

[0008] Below in conjunction with accompanying drawing this embodiment will be further described

[0009] Depend on Figure 1-2 It can be seen that a solar panel and a battery power supply 1 are installed on the outer upper end of the transformer oil conservator 2, four oil conservator brackets 3 are connected to the lower end of the transformer oil conservator, and four oil conservator brackets are respectively connected between the oil conservator bracket and the transformer oil tank. The link hinge mechanism 4 is respectively connected with four groups of two or two groups of sensors 5 on the four-link hinge mechanism. Oil level gauges 6 are respectively installed on both sides of the oil tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com