A preparation method of a special heating container for microwave synthesis of nanomaterials

A technology of nanomaterials and heating containers, applied in chemical instruments and methods, chemical/physical/physicochemical processes of energy application, chemical/physical/physicochemical processes, etc., can solve the problem of poor crystallinity of synthetic nanomaterials, The problem of uneven heating of synthetic materials and high temperature of the outer wall of the container can achieve the effect of improving microwave transmittance, small stress and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

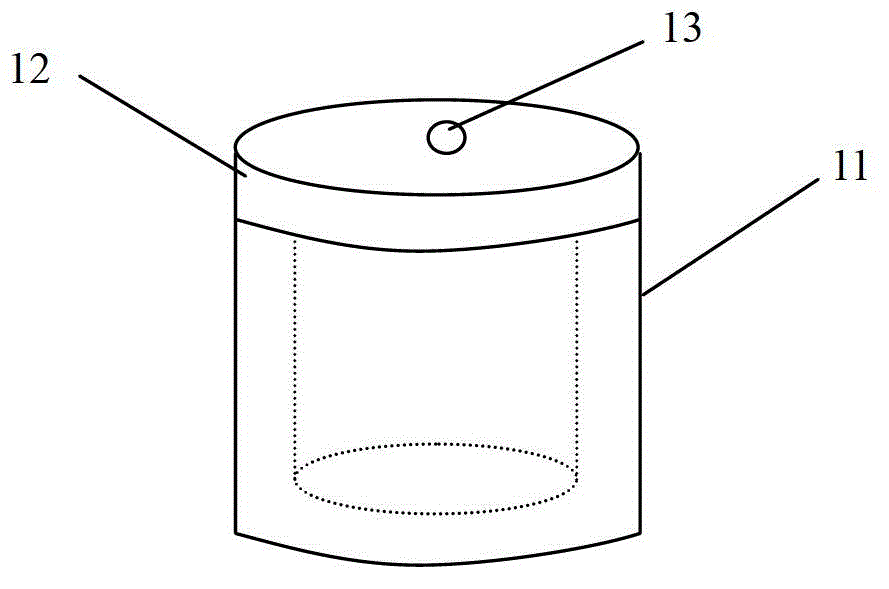

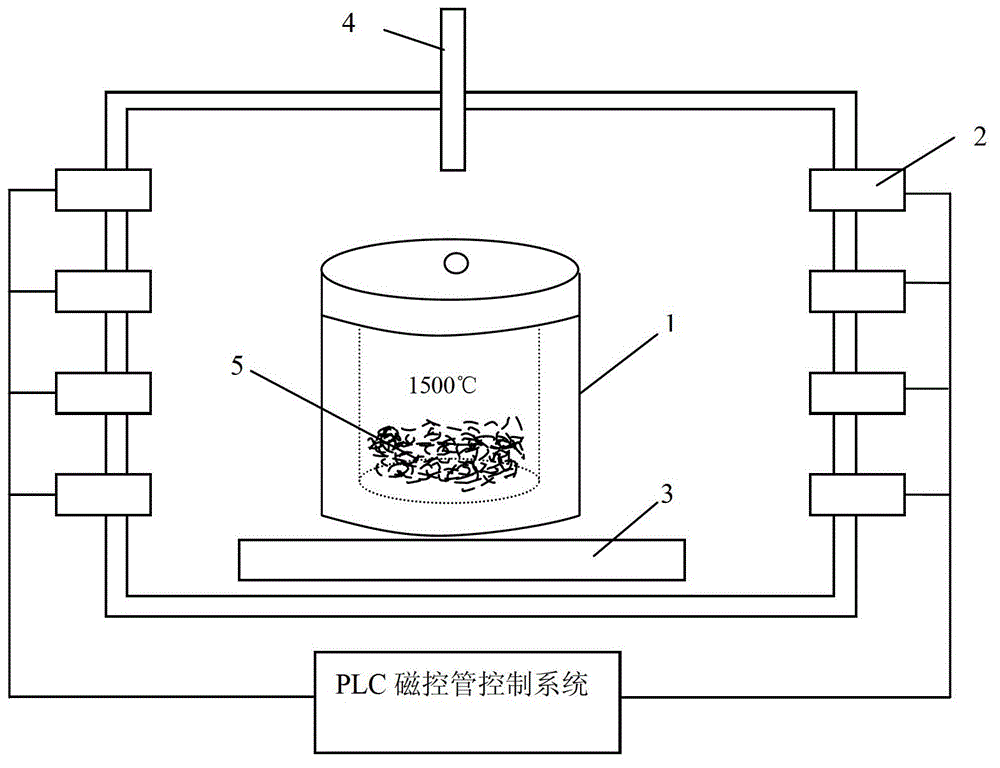

[0033] A method for preparing a special heating container for microwave synthesis of nanomaterials, comprising the following steps:

[0034] 1. Soak alumina ceramic fiber porous composite material (purchased from Henan Sanmenxia Xihongtai Furnace Technology Co., Ltd.) in distilled water. After it is completely wetted, use a colloid mill to pulverize the fiber so that the maximum length of a single fiber does not exceed 5mm.

[0035] 2. Mix distilled water and ethanol at a volume ratio of 1:1, then add 4ml of hydrochloric acid (according to 500ml of water), and then slowly add ethyl orthosilicate with a burette, while stirring continuously, the weight ratio of ethyl orthosilicate to ethanol The ratio is 1:1, and the prepared tetraethyl orthosilicate hydrolyzate is left to age for 2 hours.

[0036] 3. Mix the above-mentioned ethyl orthosilicate hydrolyzate and alumina ceramic fiber porous composite material (1:3 weight ratio) evenly, put them into a mold and press them into shap...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is only:

[0044] Utilize long-chain alkanol (isopropanol) instead of ethanol to prepare tetraethyl orthosilicate precursor (tetraethyl orthosilicate hydrolyzate), and the performance of the obtained heating container is as follows:

[0045] Maximum temperature resistance: 2000°C, thermal conductivity: 0.017W / m.k, thermal expansion coefficient: 1.6×10 -7 mm / ℃, compressive strength: 5.2Mpa, flexural strength: 1.7Mpa. The porosity is 86%-94%, and the bulk density is 0.6g / cm 3 , with a weight of 0.48Kg.

Embodiment 3

[0047] The difference between this embodiment and embodiment 1 is only:

[0048] The prepared tetraethyl silicate precursor and the alumina ceramic fiber porous composite material have a weight ratio of 1:3.5, and the properties of the prepared heating vessel are as follows:

[0049] Maximum temperature resistance: 2000°C, thermal conductivity: 0.017W / m.k, thermal expansion coefficient: 1.6×10 -7 mm / ℃, compressive strength: 4.5Mpa, flexural strength: 1.3Mpa. The porosity is 88%-96%, and the bulk density is 0.7g / cm 3 , with a weight of 0.53Kg.

[0050] To sum up, the present invention improves the thermal shock resistance of the material in the microwave field for rapid heating of the heating container, and is not easy to burst, and the toughness of the material is enhanced by using ceramic fibers. The microwave transmittance is significantly improved by selecting a suitable low dielectric loss material and the stress-reducing shape design, the thermal insulation effect is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com