Injection mold for magnetic conduction ring assembly and manufacturing method thereof

A technology of injection mold and manufacturing method, which is applied in the direction of household appliances, other household appliances, gears, etc., can solve the problems of affecting the magnetic field induction effect, reducing the consistency and reliability of sensors, and low mechanical strength, so as to improve consistency and reliability Sexuality, good conduction and distribution, simple stamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

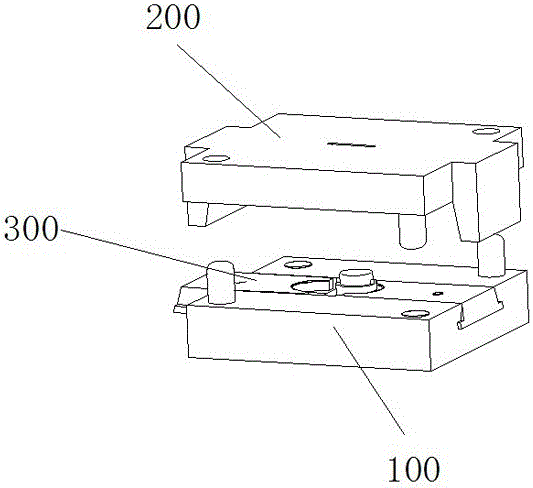

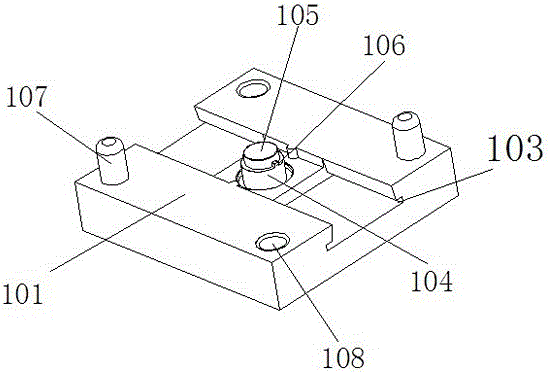

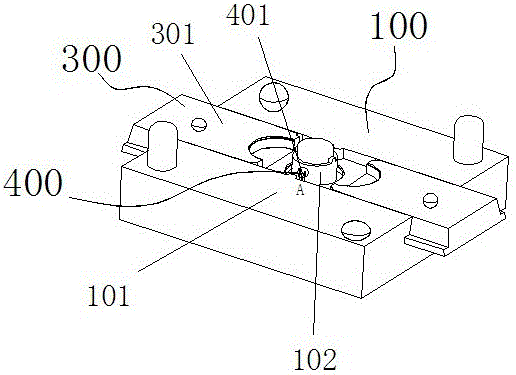

[0049] Such as Figure 1-10 As shown, an injection mold of a magnetic ring assembly includes a lower mold assembly 100 and an upper mold assembly 200 and a positioning mechanism 300 provided on the lower mold assembly, and the lower mold assembly 100 includes a lower mold assembly The mold 101 , the mandrel 102 provided on the lower mold 101 and the guiding device 400 provided on the mandrel 102 , the upper mold assembly 200 includes the upper mold 201 and the injection gate 202 arranged on the upper mold 201 .

[0050] In this embodiment, the positioning mechanism 300 includes a slider 301 symmetrically arranged on the upper surface of the lower mold 101, and one end of the slider 301 is provided with an open groove 302. When placed, the open groove 302 of the slider 301 is placed opposite , two open grooves 302 form a circle just surrounding the outer end surface of the magnetic conduction ring, which is used to position the magnetic conduction ring; both sides of the slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com