Stereo image printed matter and stereo image printing process

A technology of three-dimensional images and printed matter, applied in the field of three-dimensional image printing, can solve the problems of incomplete change, blurred picture, afterimage, etc., and achieve the effect of smooth and smooth display, reduced difficulty and stable production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A three-dimensional image printing process, characterized in that: comprising the following steps:

[0052] Step 1: Prepare a microlens array, select a transparent substrate, prepare a microlens array on the transparent substrate, and the mirror focus of the microlens falls on the transparent substrate;

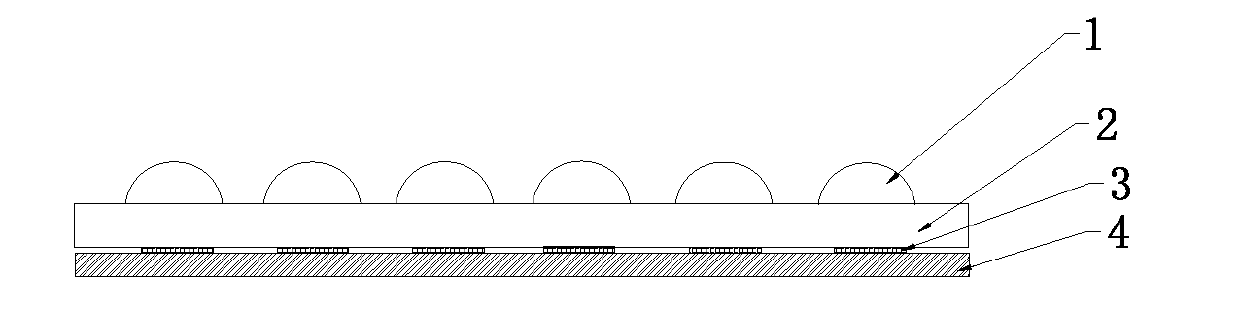

[0053] Step 2: To print the three-dimensional pattern, first use the graphics software to prepare the three-dimensional pattern to be printed, then adjust the size of the three-dimensional pattern to be smaller than the area of the microlens, and then arrange the three-dimensional pattern to the same pattern as the microlens array, the specific array pattern such as figure 1 As shown, then the output pattern is made into a positive film, and the picture of the positive film is developed on the screen plate, and then rinsed, and then the pattern is printed on the back of the substrate by screen printing after the screen plate is dry. Three-dimensional printing is obt...

Embodiment 2

[0057] A three-dimensional image printing process, characterized in that: comprising the following steps:

[0058] Step 1: Prepare a microlens array, select a transparent substrate, prepare a microlens array on the transparent substrate, and the mirror focus of the microlens falls on the transparent substrate.

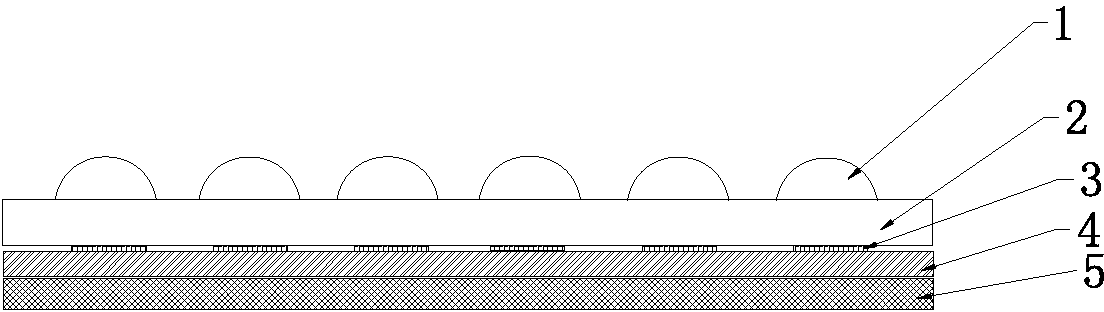

[0059] Step 2: To print the three-dimensional pattern, first use the graphics software to prepare the three-dimensional pattern to be printed, then adjust the size of the three-dimensional pattern to be smaller than the area of the microlens, and then arrange the three-dimensional pattern to the same pattern as the microlens array, the specific array pattern such as figure 2 As shown, then the output pattern is made into a positive film, the image of the positive film is developed on an offset plate, and then washed, and then the pattern is printed on the back of the substrate by an offset printing method to obtain a three-dimensional print.

[0060] Step 3: Print ...

Embodiment 3

[0064] A three-dimensional image printing process, characterized in that: comprising the following steps:

[0065] Step 1: Prepare a microlens array, select a transparent substrate, prepare a microlens array on the transparent substrate, and the mirror focus of the microlens falls on the transparent substrate.

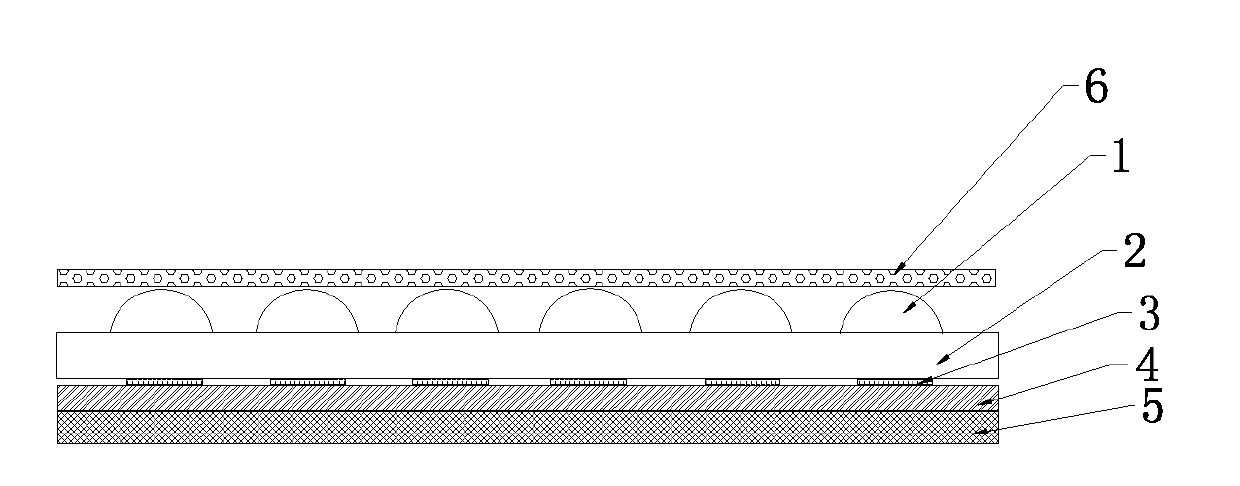

[0066] Step 2: To print the three-dimensional pattern, first use the graphics software to prepare the three-dimensional pattern to be printed, then adjust the size of the three-dimensional pattern to be smaller than the area of the microlens, and then arrange the three-dimensional pattern to the same pattern as the microlens array, the specific array pattern such as image 3 As shown, then the output pattern is made into a positive film, and the image of the positive film is developed on an offset plate, and then washed, and then the pattern is printed on the back of the substrate by an offset printing method to obtain a three-dimensional print.

[0067] Step 3: Pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com