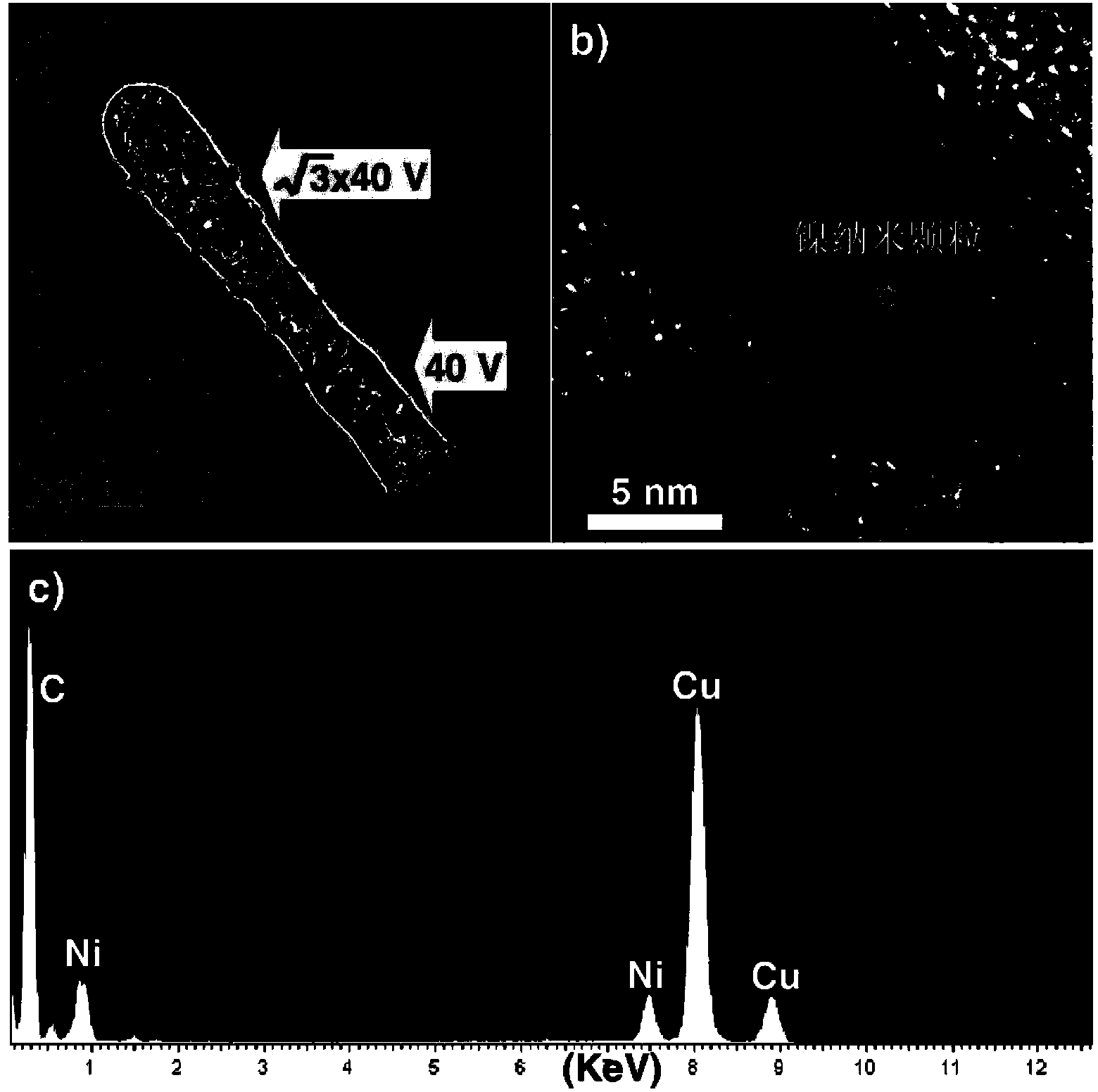

Carbon nano bottle containing nickel nano particles and method for preparing carbon nano bottle

A carbon nano-bottle and nano-particle technology, applied in nano-carbon, nano-technology, nano-technology and other directions, can solve the problems of inability to obtain carbon nano-bottle, difficult to effectively store substances, etc., and achieve simple preparation method, avoid pollution, and controllability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The concrete steps of preparation are:

[0039] Step 1, first place the aluminum sheet in an oxalic acid solution with a temperature of 0.5°C and a concentration of 0.25mol / L, and after anodizing at a constant voltage of 35V for 8 hours, place it in an oxalic acid solution with a temperature of 55°C and a concentration of 6wt%. Soak in a mixed solution of phosphoric acid and 1.8wt% chromic acid for 4 hours. It was then placed under the same conditions for anodic oxidation for 5 minutes to obtain a blind hole porous alumina template.

[0040] Step 2, first place the porous alumina template with blind holes in an oxalic acid solution with a temperature of 0.5 °C and a concentration of 0.035 mol / L, at a constant pressure of Anodizing for 11 minutes. Then soak it in a phosphoric acid solution with a temperature of 25° C. and a concentration of 0.5 mol / L for 22 minutes to obtain a bottle-shaped porous alumina template.

[0041] Step 3, first place the bottle-shaped hole-s...

Embodiment 2

[0045] The concrete steps of preparation are:

[0046] Step 1, first place the aluminum sheet in an oxalic acid solution with a temperature of 0.75°C and a concentration of 0.28mol / L, anodize it at a constant voltage of 39V for 7.5h, then place it at a temperature of 58°C and a concentration of 6wt% Soak in a mixed solution of phosphoric acid and 1.8wt% chromic acid for 3.8 hours. It was then placed under the same conditions for anodic oxidation for 4.5 minutes to obtain a blind hole porous alumina template.

[0047] Step 2, first place the blind-hole porous alumina template in an oxalic acid solution with a temperature of 0.75 °C and a concentration of 0.038 mol / L, at a constant pressure of Lower anodizing for 10.5min. Then soak it in a phosphoric acid solution with a temperature of 28° C. and a concentration of 0.75 mol / L for 21.5 minutes to obtain a bottle-shaped porous alumina template.

[0048] Step 3, first place the bottle-shaped hole-shaped porous alumina template ...

Embodiment 3

[0052] The concrete steps of preparation are:

[0053] Step 1, first place the aluminum sheet in an oxalic acid solution with a temperature of 1°C and a concentration of 0.3mol / L, and after anodizing at a constant voltage of 43V for 7 hours, place it in an oxalic acid solution with a temperature of 60°C and a concentration of 6wt%. Soak in a mixed solution of phosphoric acid and 1.8wt% chromic acid for 3.5 hours. It was then placed under the same conditions for anodic oxidation for 4 minutes to obtain a porous alumina template with blind holes.

[0054] Step 2, first place the blind-hole porous alumina template in an oxalic acid solution with a temperature of 1 °C and a concentration of 0.04 mol / L, under constant pressure of Anodizing for 10 minutes. Then soak it in a phosphoric acid solution with a temperature of 30° C. and a concentration of 1 mol / L for 21 minutes to obtain a bottle-shaped porous alumina template.

[0055] Step 3, first place the bottle-shaped hole-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com