Preparation method of long-dimension dispersion-strengthened copper-based composite material and its melting and casting device

A technology of copper-based composite materials and dispersion-strengthened copper, which is applied in the field of composite material preparation technology and equipment, copper-based composite material preparation technology and special equipment, to achieve the effects of improving productivity, avoiding small-scale agglomeration, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

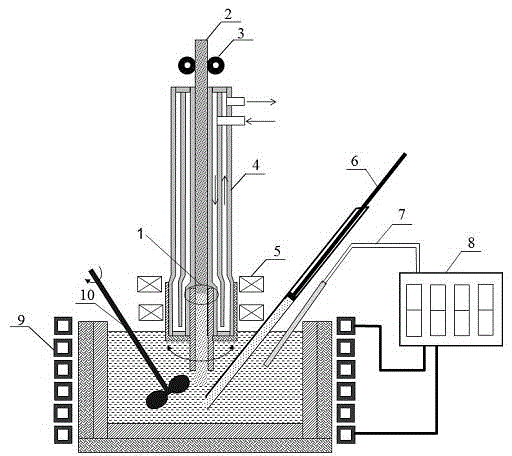

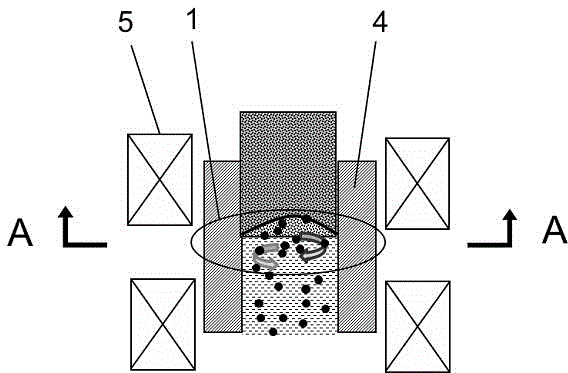

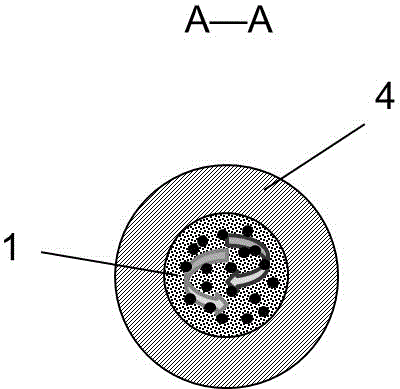

[0045] In this example, see figure 2 and image 3 , a long-dimensioned Al 2 o 3 Preparation method of dispersion strengthened Cu-based composite material, using Al 2 o 3 As the reinforced phase dispersion material, copper is used as the matrix material, that is, Al is added to the copper melt according to the composition ratio of 5% by mass fraction. 2 o 3 Ceramic powder particles are mechanically stirred for the copper melt, and two opposing rotating magnetic fields are combined to generate a strong turbulent flow at the front of the solidification interface of the copper melt, fully stirred, and the upward continuous casting process is adopted to make the upward continuous Cu-Al prepared during casting 2 o 3 Composite grain refinement, and make the strengthening phase Al 2 o 3 Dispersed particles are uniformly distributed in the copper-based composites, thereby preparing long-sized Al 2 o 3 Dispersion strengthened Cu matrix composites.

[0046] In this example, ...

Embodiment 2

[0052] This embodiment is basically the same as Embodiment 1, especially in that:

[0053] In this embodiment, silicon carbide whiskers are used as the reinforced phase dispersion material, and the silicon carbide whiskers used are fine whiskers with a diameter of less than 10 μm and an aspect ratio exceeding 20. Also at 1150 ° C, the powder pushing device 6 Send the fine silicon carbide whiskers into the bottom of the copper liquid at a speed of 5mm / s. The silicon carbide whiskers have a density lower than that of the copper liquid, and will slowly float up under the action of buoyancy. At the front of the solid-liquid solidification interface, it is evenly distributed under the action of the strong turbulent flow generated by the 200mT rotating magnetic field, and is engulfed by the solidification interface. The speed is 5mm / s, and the copper liquid is continuously replenished to stabilize the liquid level at a certain height, and then the addition of silicon carbide whisker...

Embodiment 3

[0055] This embodiment is basically the same as the previous embodiment, and the special features are:

[0056] In this embodiment, graphite particles with a diameter of 0.1 μm are sent into the bottom of the copper liquid as a strengthening phase, and the addition rate is the same as that of the previous example. / s, under the action of a 200mT rotating magnetic field, the graphite particle dispersion-strengthened Cu-based composite was prepared with a strengthening phase volume fraction of 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com