Pipe connection structure for powder material guide

A technology for connecting structure and powder, which is applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, mechanical equipment, etc. and other problems to achieve the effect of smooth material guiding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that the features in the various embodiments of the present invention may be combined with each other in the absence of explicit limitation or conflict. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0022] In order to overcome the defects of the pipeline connection structure used for powder material guide in the prior art, the present invention provides an improved pipeline connection structure used for powder material guide.

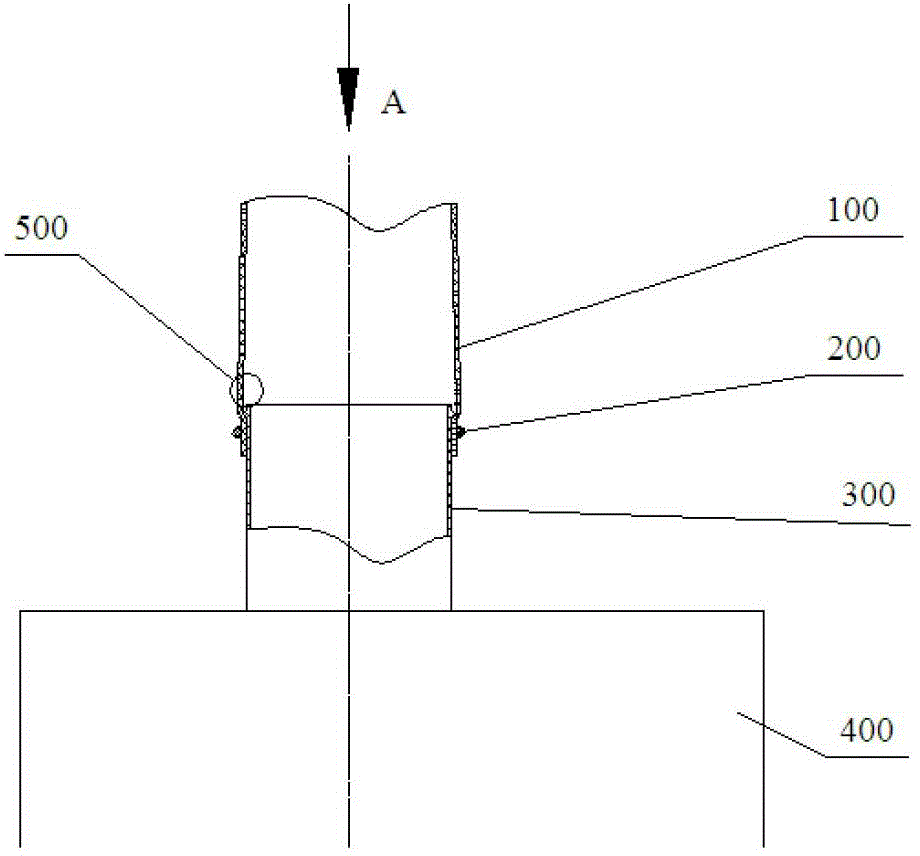

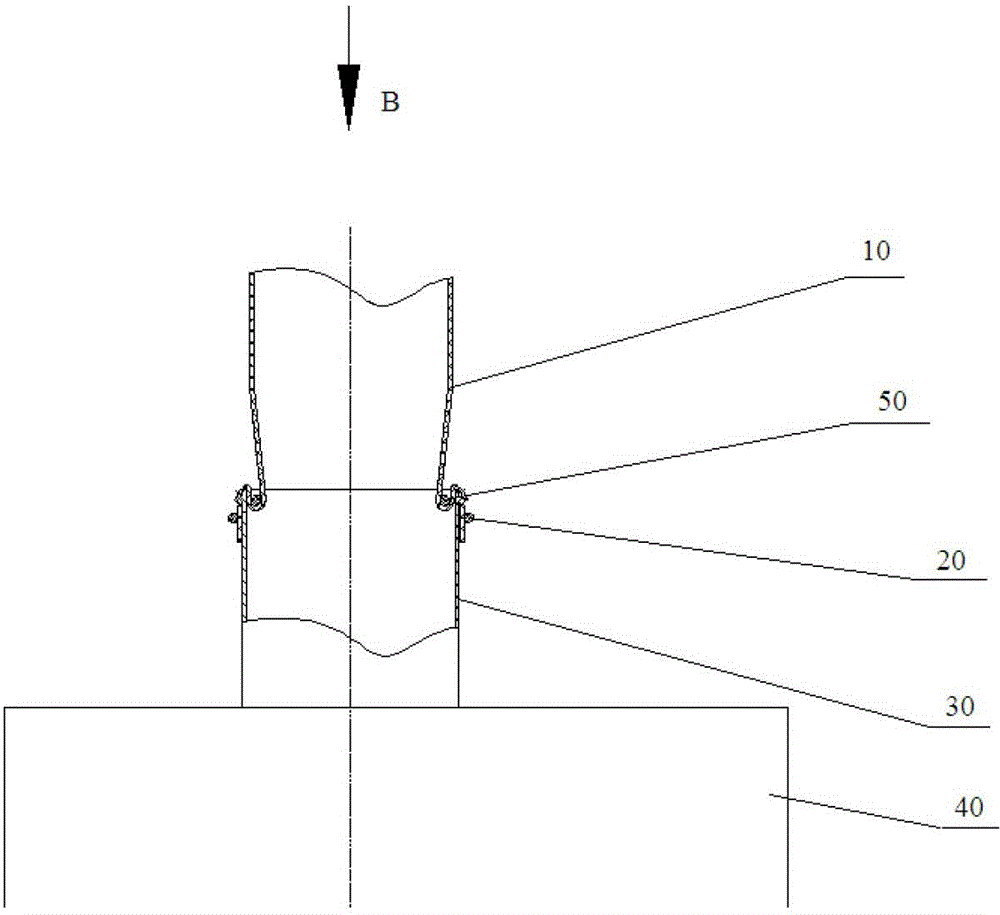

[0023] figure 2 It is a structural schematic diagram of a pipeline connection structure for powder material guide according to an embodiment of the present invention. like figure 2 As shown, the pipeline connection structure includes a soft cloth pipe 10 and a hard pipe 30 . The lower end of the soft cloth pipe 10 is used as the first end, and is connected with the upper end of the hard pipe 30 , that is, the first end. The upper end of soft cloth pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com