Three-level heated waste water waste heat recovery device of heat-pump water heater

A waste heat recovery device, heat pump water heater technology, applied in heat recovery systems, fluid heaters, energy-saving heating/cooling, etc., can solve the problems of small temperature difference of waste water and low waste heat recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

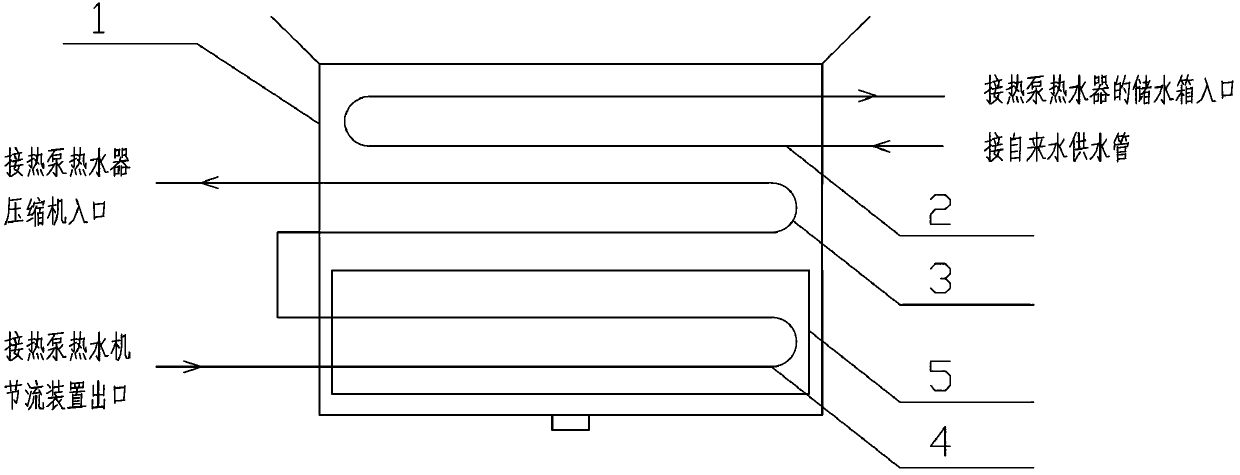

[0009] Such as figure 1 As shown, a three-stage waste heat recovery device for heat pump water heaters includes a main water collection tank 1 for collecting hot waste water. Specifically, the main water collection tank 1 is installed at the bottom of the bathroom. A heat exchanger 2, a first evaporator 3, and a second evaporator 4 are sequentially installed in the main water collecting tank 1 from top to bottom, wherein the second evaporator 4 is installed in a main water collecting tank 1 and in In the auxiliary water collection tank 5 below the first evaporator 3, the heat exchanger 2 is connected in series to the water inlet pipe of the heat pump water heater, the first evaporator 3 and the second evaporator 4 are connected in series, and the output end of the first evaporator 3 It is connected to the inlet of the compressor of the heat pump water heater, and the input end of the second evaporator 4 is connected to the outlet of the throttling valve of the heat pump water ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap