Lifting device and method for liftable in-well equipment in in-situ leaching uranium mining mine

An in-situ leaching uranium mining and lifting well technology, which is applied in the direction of lifting devices, lifting frames, earthwork drilling and mining, etc., can solve the problems of equipment lifting in the well, poor passability, and high center of gravity of the lifting device, so as to increase the height of equipment and reduce the required Time, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

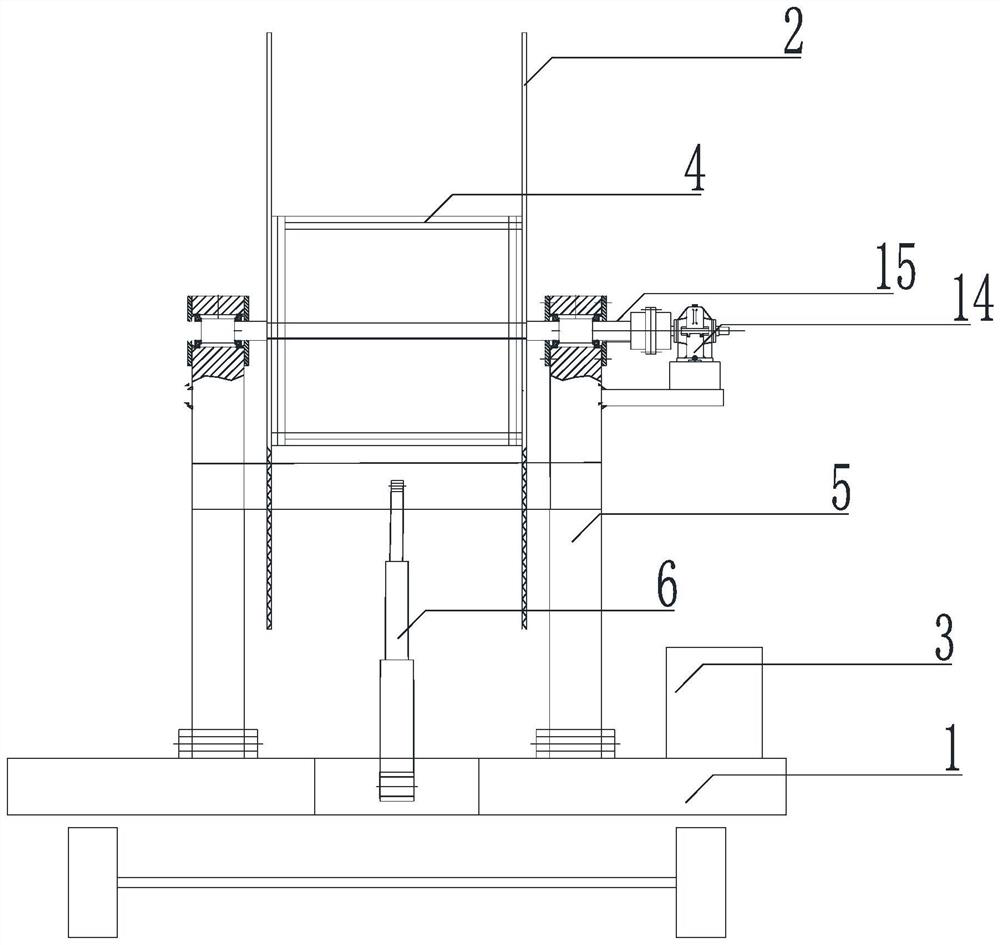

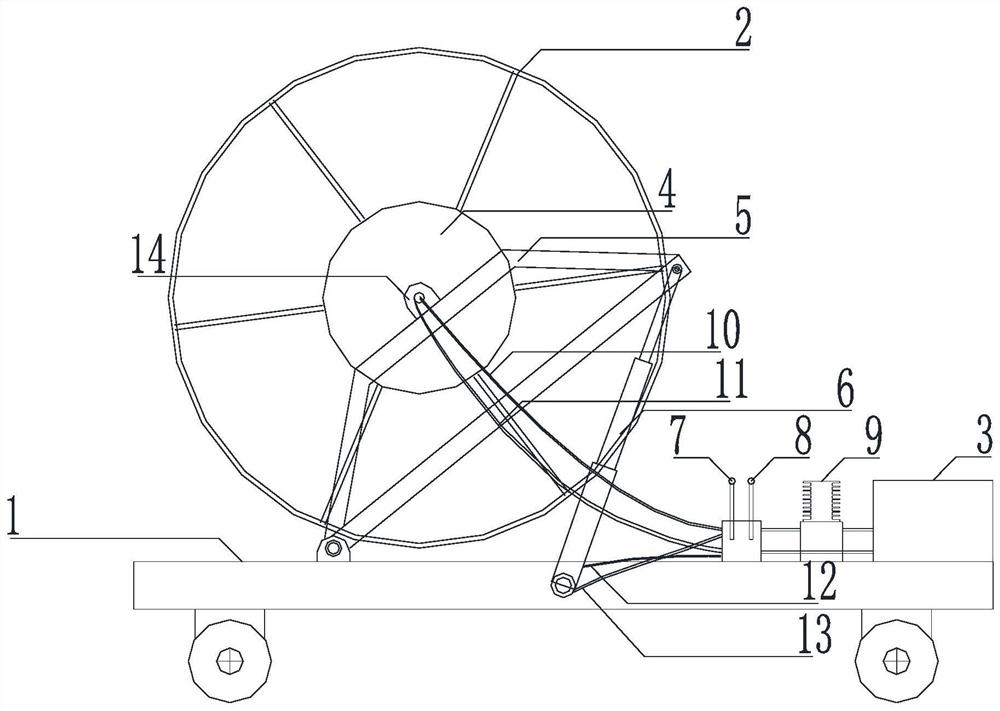

[0034] A hoisting device for hoisting equipment in an in-situ leaching uranium mining mine, which includes a vehicle frame 1, a power unit, a hoisting device and a coiling device.

[0035] The power unit includes a hydraulic pump 9, a rotary controller 8, a high-pressure oil pipe group, a hydraulic motor 14 and a transmission shaft 15: wherein the high-pressure oil pipe group includes a hydraulic oil pipe A10, a hydraulic oil pipe B11, a hydraulic oil pipe C12, and a hydraulic oil pipe D13; the rotation control The upper inlet port of the device 8 is connected to the output port of the hydraulic pump 9, the upper outlet port of the rotary controller 8 is connected to the inlet port of the hydraulic motor 14, the lower inlet port of the rotary controller 8 is connected to the outlet port of the hydraulic motor 14, and the rotary controller 8 The lower outlet port of the hydraulic pump 9 is connected to the inlet port of the hydraulic oil tank 3, and the inlet port of the hydraul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap