Large two-stroke compression-ignited internal combustion engine with dual fuel systems

A technology for internal combustion engines and compression ignition, applied to internal combustion piston engines, combustion engines, motor-driven engines, etc., can solve the problems of increasing the initial cost of the engine, increasing the complexity and maintenance cost of the engine, and achieving the goal of reducing cost and complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

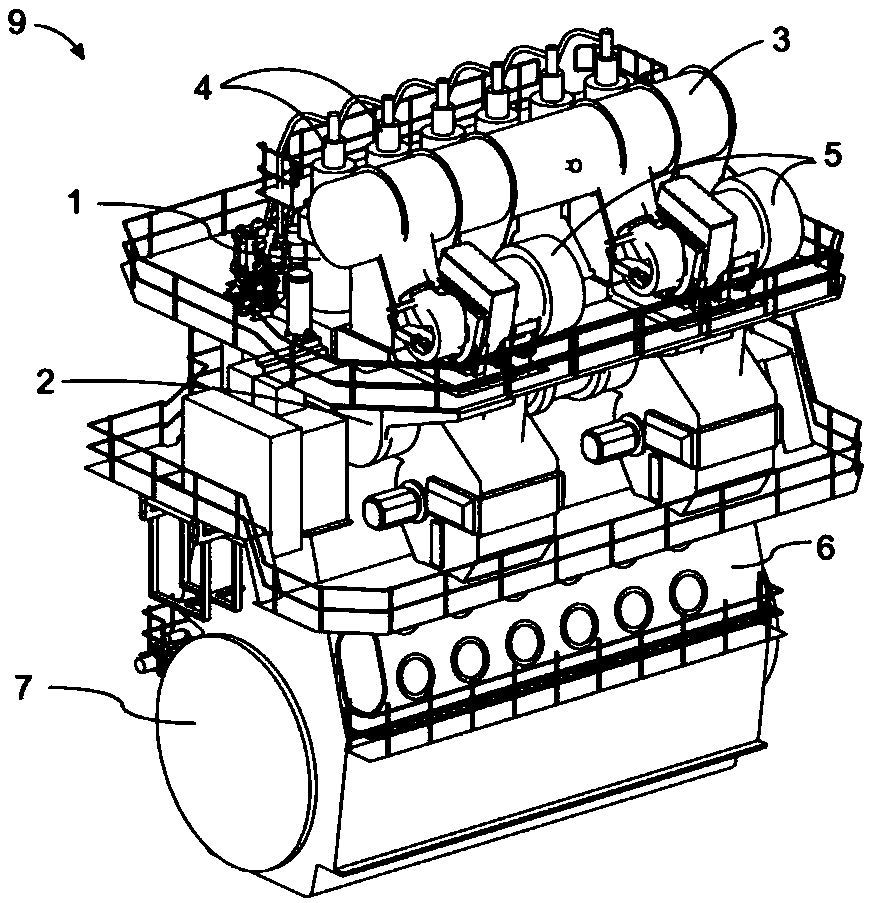

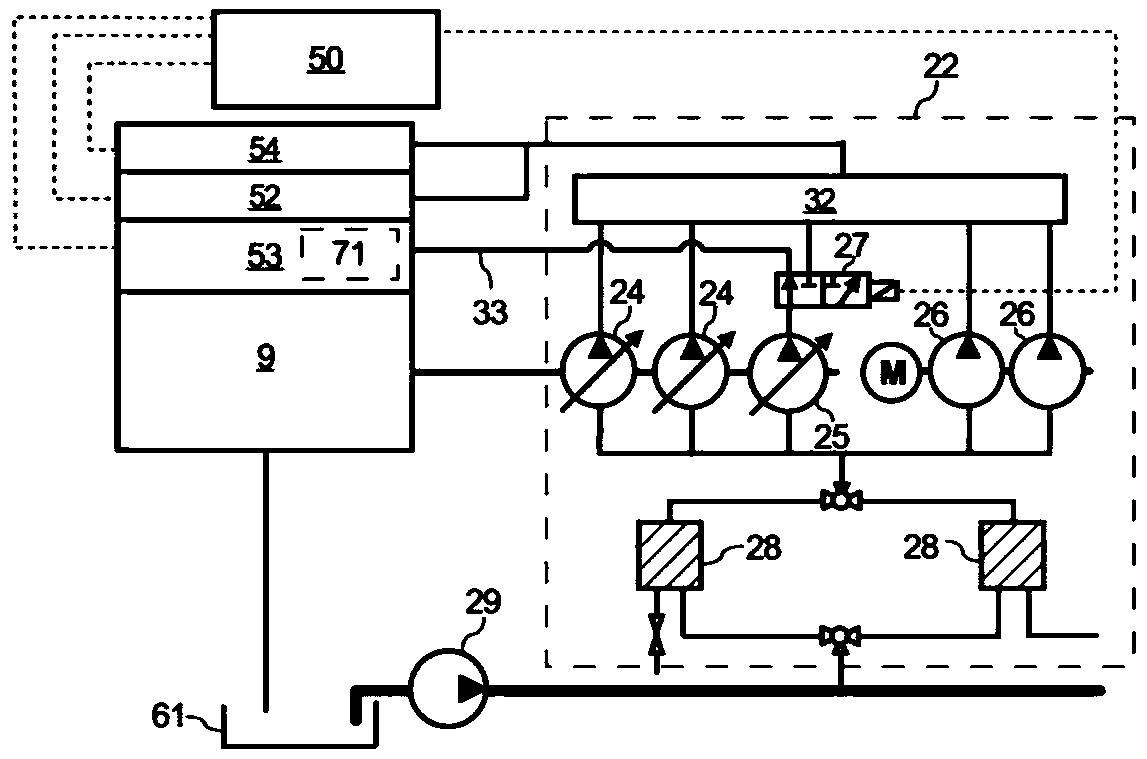

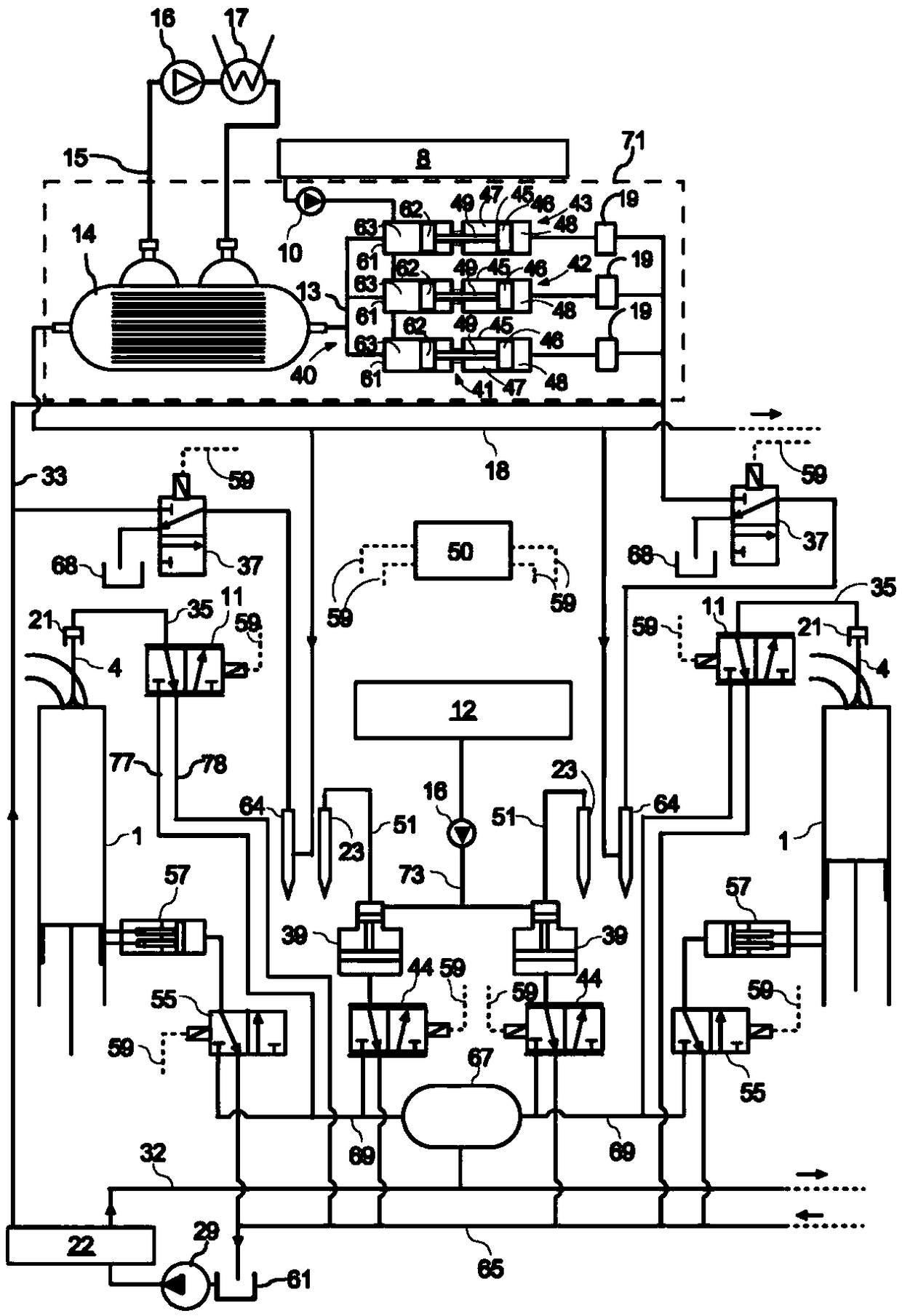

[0047] In the following detailed description, a fuel supply system for a large two-stroke low-speed turbocharged compression ignition internal combustion engine 9 with a crosshead will be described with reference to an exemplary embodiment. figure 1 A large low-speed turbocharged two-stroke diesel engine 9 with steering wheels 7 and a crosshead is shown. In this exemplary embodiment, the engine has six in-line cylinders. A large low-speed turbocharged two-stroke diesel engine usually has between four and fourteen in-line cylinders, which are carried by a cylinder frame carried by the engine frame 6. The engine 9 may be used, for example, as a main engine in a ship or as a stationary engine for operating a generator in a power station. The total output of the engine may be in the range of 1,000 kW to 110,000 kW, for example.

[0048] In this exemplary embodiment, the engine 9 is a two-stroke single-flow type compression ignition engine having a scavenging port at the lower region...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap