Coupling structure between linear type pulse tube refrigerator and infrared device and manufacturing method for same

A technology of pulse tube refrigerator and coupling structure, which is applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve the problems of low refrigeration efficiency, loose structure of the whole machine, and large aspect ratio of cold fingers, etc., to achieve enhanced The effect of reliability, compact structure and efficient transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

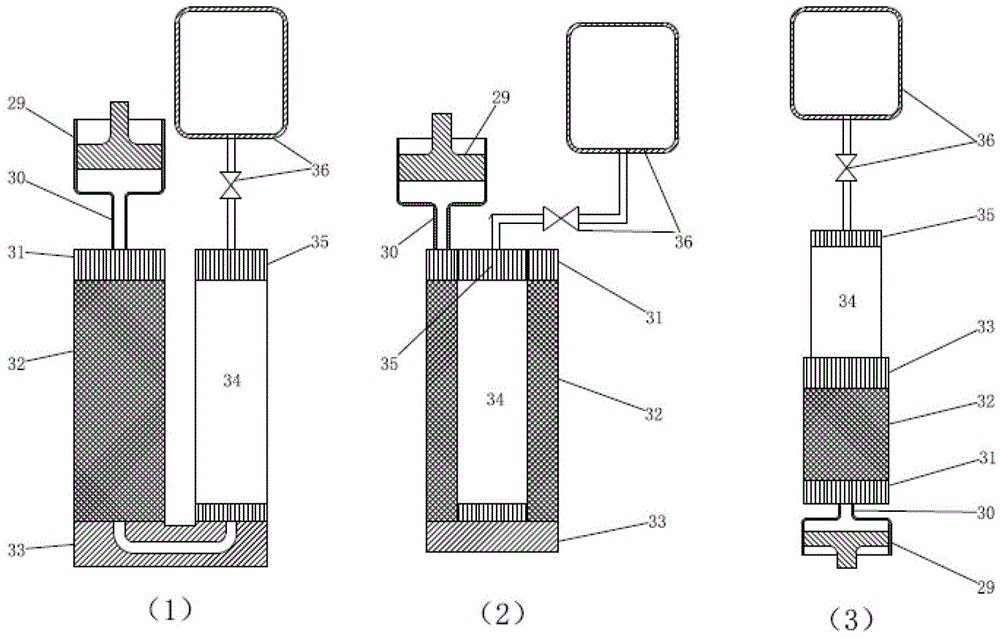

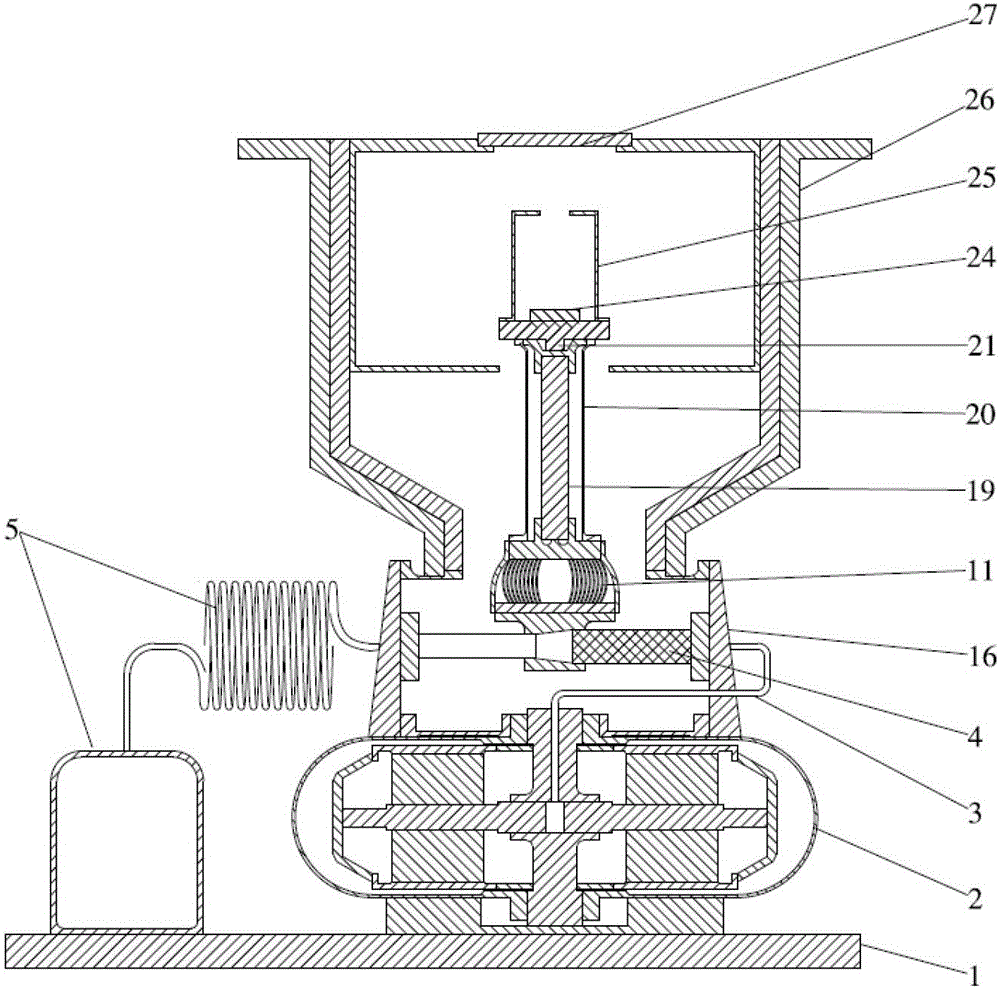

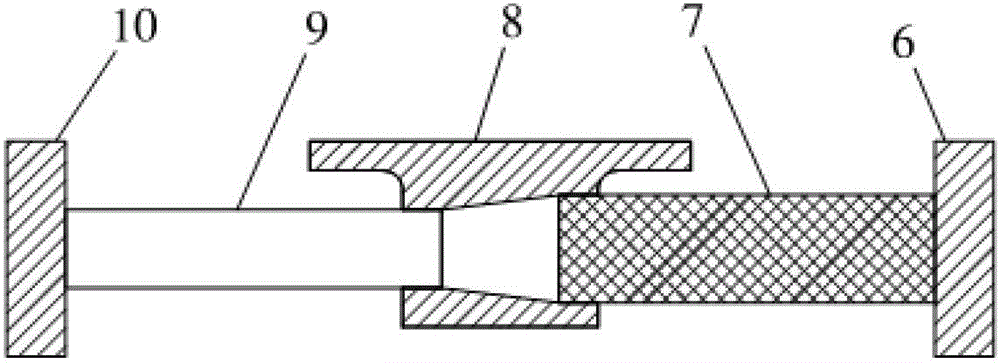

[0032] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

[0033] An invented coupling structure suitable for linear pulse tube refrigerators and infrared devices consists of a main base 1, a compressor 2, connecting pipes 3, a linear pulse tube cold finger 4, a phase modulation mechanism 5, and a cold finger support shell 16. Composed of flexible heat conduction belt assembly 11, columnar cold chain 19, cold chain reinforcement support 20, device cooling platform 21, infrared device 24, cold screen 25, device Dewar 26 and Dewar window 27. The main base 1 serves as the supporting base of the entire coupling structure, and at the same time serves as the heat dissipation structure of the compressor 2 and the phase modulation mechanism 5; the compressor 2 adopts a double-piston opposed structure; The finger 4 and the phase modulation mechanism 5 together form a linear pulse tube refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com