Floating cylinder type liquid level indicating device

An indicating device and buoy-type technology, which is applied in the direction of buoy liquid level indicator, etc., can solve the problems of poor sensitivity of liquid level indication, easy corrosion of pulleys, jamming and other problems, so as to avoid liquid level indication error, facilitate reading liquid level, The effect of reducing lifting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

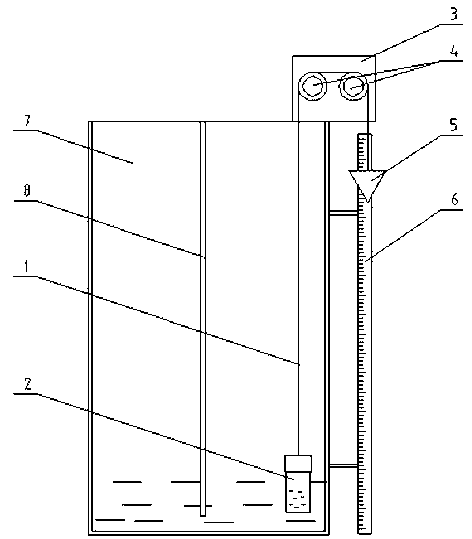

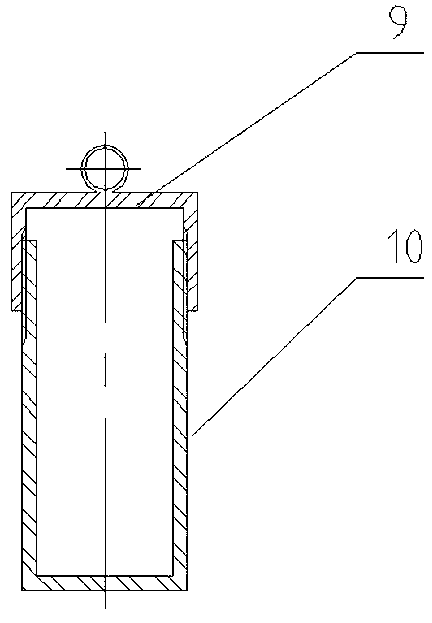

[0014] Example 1 figure 1 , 3 Shown: a float type liquid level indicator device, including a container 7 filled with liquid; a support plate 3 is provided at the upper end of the container 7, and two pulleys 4 are installed on the horizontal line of the support plate 3, one of which is a pulley 4 Located inside the extension line of the side wall of the container 7, the other pulley 4 is located outside the extension line of the side wall of the stainless steel container 7; one end of the connecting line 2 is connected to the pontoon 1 in the container 7, and the other end after bypassing the pulley 4 is connected to the liquid level The liquid level indicator block 5 beside the scale 6 is connected; the liquid level scale 6 is installed on the outside of the side wall of the container 7 or is printed on the side wall of the container 7. The pontoon 1 is cylindrical and made of corrosion-resistant non-metallic materials; the pontoon 1 is composed of a cylinder body 10 and a cyli...

Embodiment 2

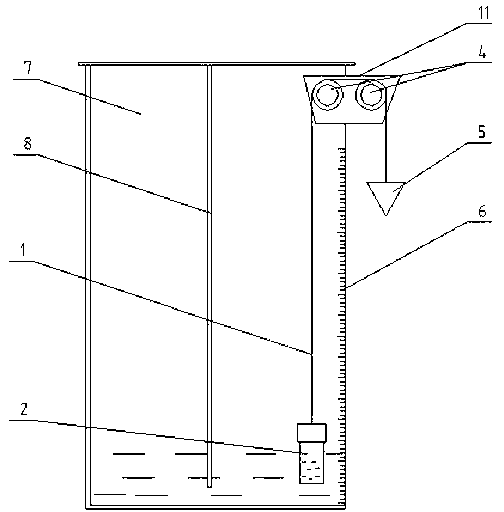

[0015] Example 2 such as figure 2 As shown: The float type liquid level indicator device of this embodiment is used for the liquid level measurement of ammonium molybdate solution; the ammonium molybdate solution is more expensive, and the top cover of the container 7 must not pass through the connection line of the liquid level device to prevent Impurities such as rainwater enter the storage tank to contaminate the solution. To this end, a beveled square tube 11 is provided on the upper side of the container 7, and the inner ring of the rolling bearing of the core of the pulley 4 is fixed on the support shaft of the inner wall of the beveled square tube 11. The buoy 1 is cylindrical and made of hard plastic, and the buoy cylinder body 10 and the cylinder cover 9 are connected by a sealed thread. Fill the buoy 1 with 45% volume of concentrated brine, put the buoy 1 vertically into the ammonium molybdate solution in the container 7, so that 1 / 2 of the height of the buoy 1 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com