Heating system of high-temperature working condition rolling bearing testing machine

A technology for rolling bearings and high-temperature working conditions, applied in the field of heating systems, to achieve the effect of compact structure, accurate and efficient simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

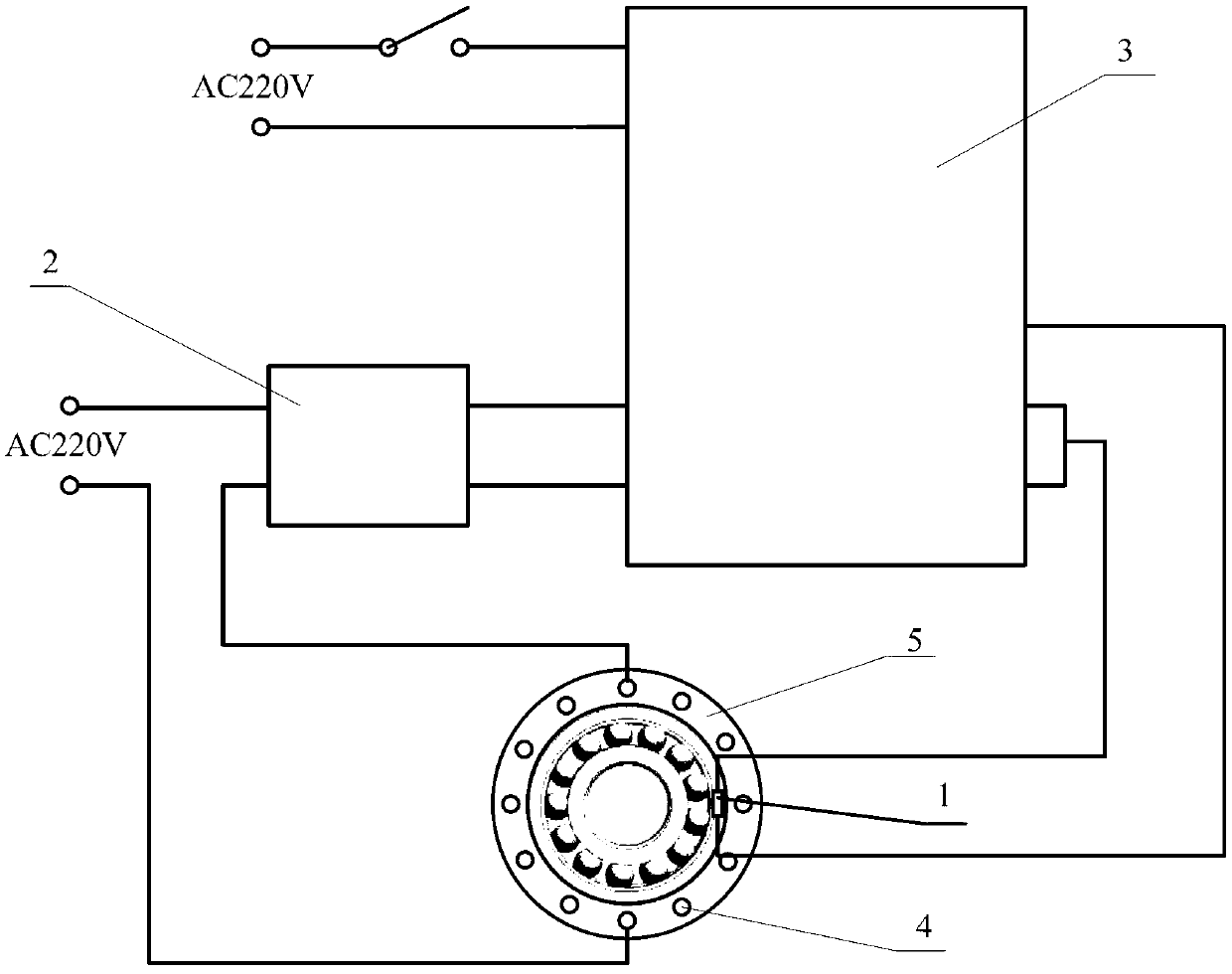

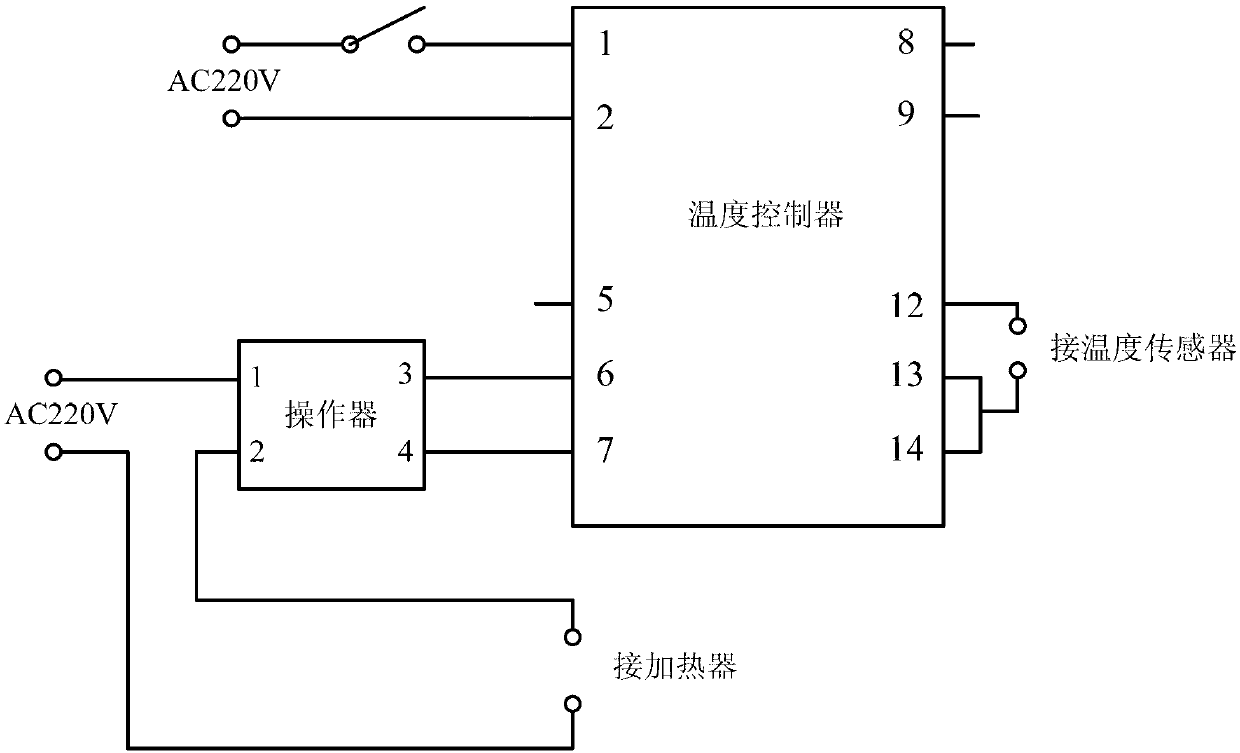

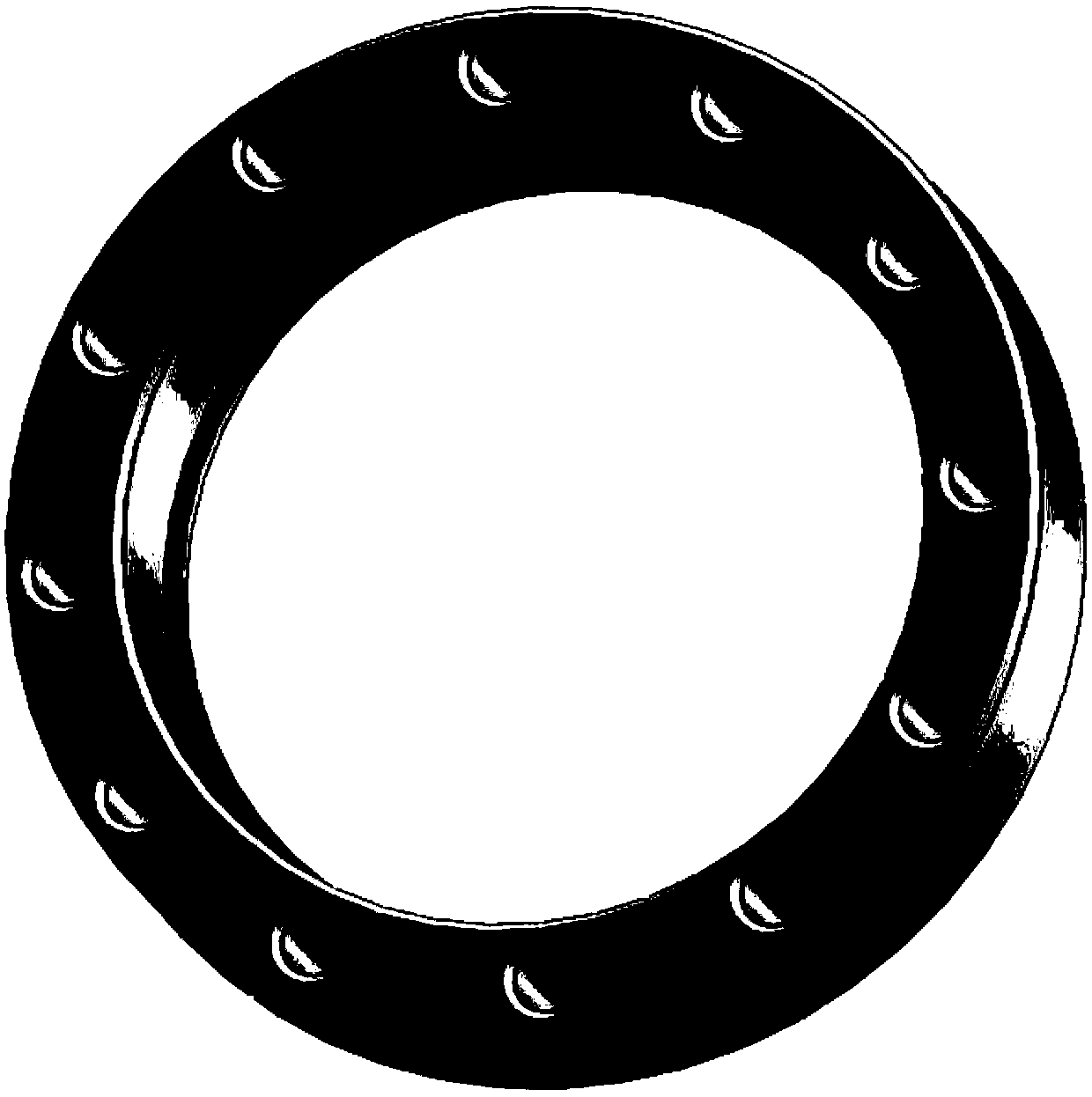

[0025] The heating system of the present invention adopts the overall scheme of heating the outer ring of the bearing by the support bushing. The supporting bushing is drilled along the circumferential direction, and the heaters are evenly arranged to heat the supporting bushing, so as to realize the heating of the outer ring of the bearing. The temperature control subsystem uses a temperature sensor to measure temperature, and a temperature controller to collect data and output control signals to control the power supply of the manipulator to automatically adjust the temperature of the system.

[0026] Taking 6020 deep groove ball high temperature bearing as the test sample below, the embodiment of the heating system of the rolling bearing testing machine under high temperature working conditions of the present invention is given: as figure 1 As shown, the heating system of the rolling bearing testing machine under high temperature conditions includes a temperature control su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com