Underwater wellhead head annulus seal surface test device capable of simultaneously loading and pressurizing

A ground test and underwater wellhead technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of high cost of testing, difficulty in precise control of ballast of large presses, loss of meaning of testing, etc. problem, to achieve the effect of easy lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

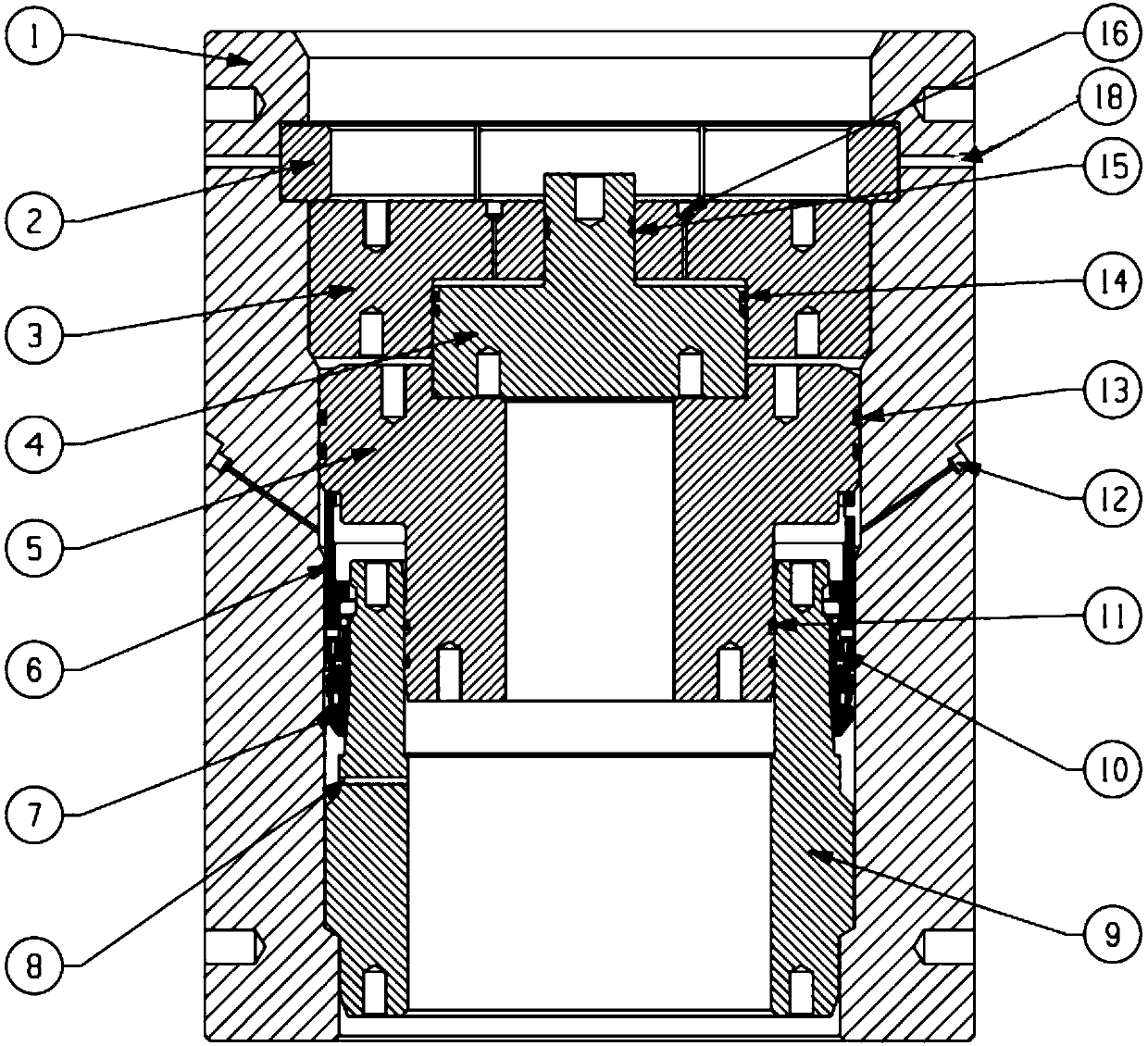

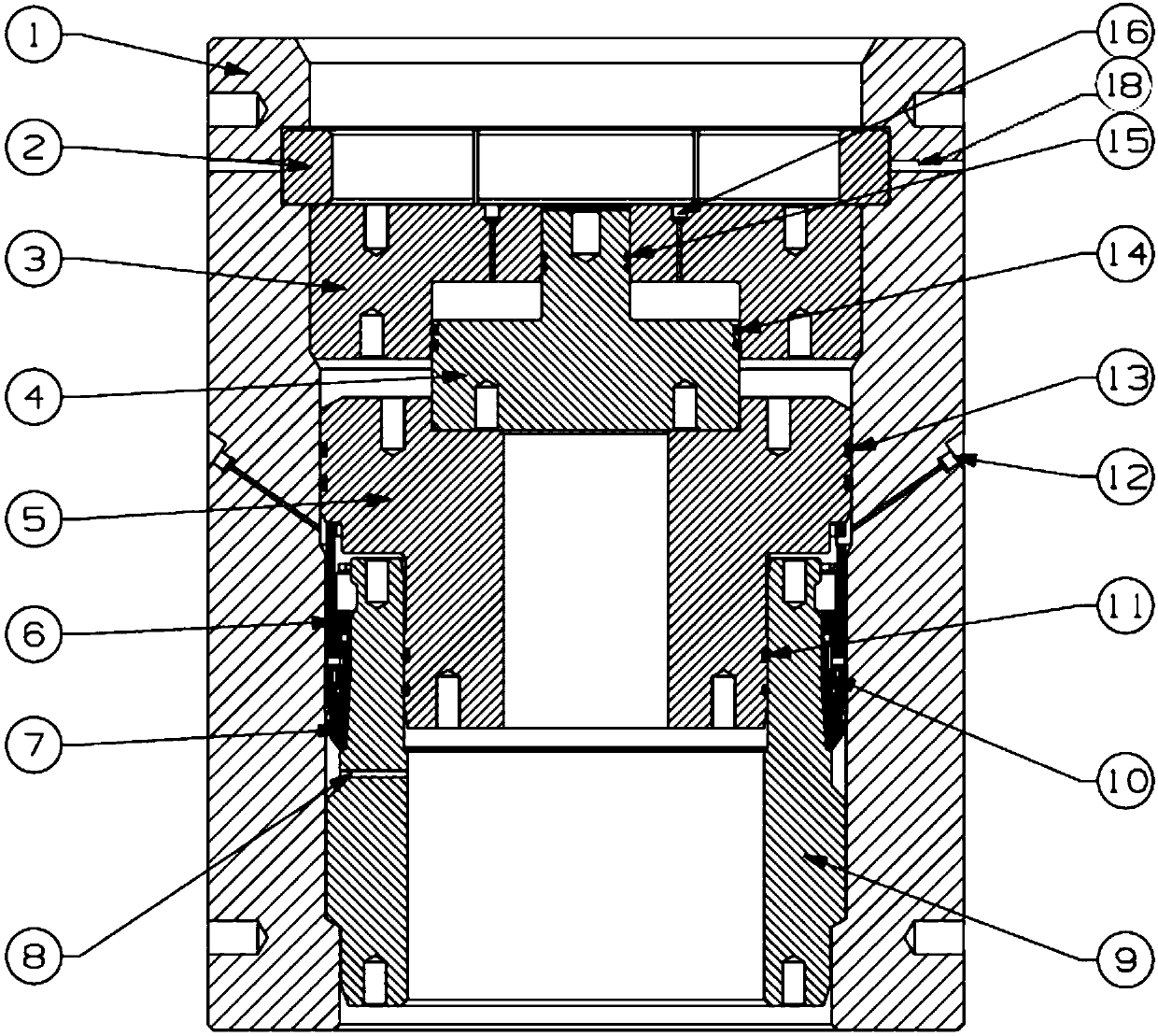

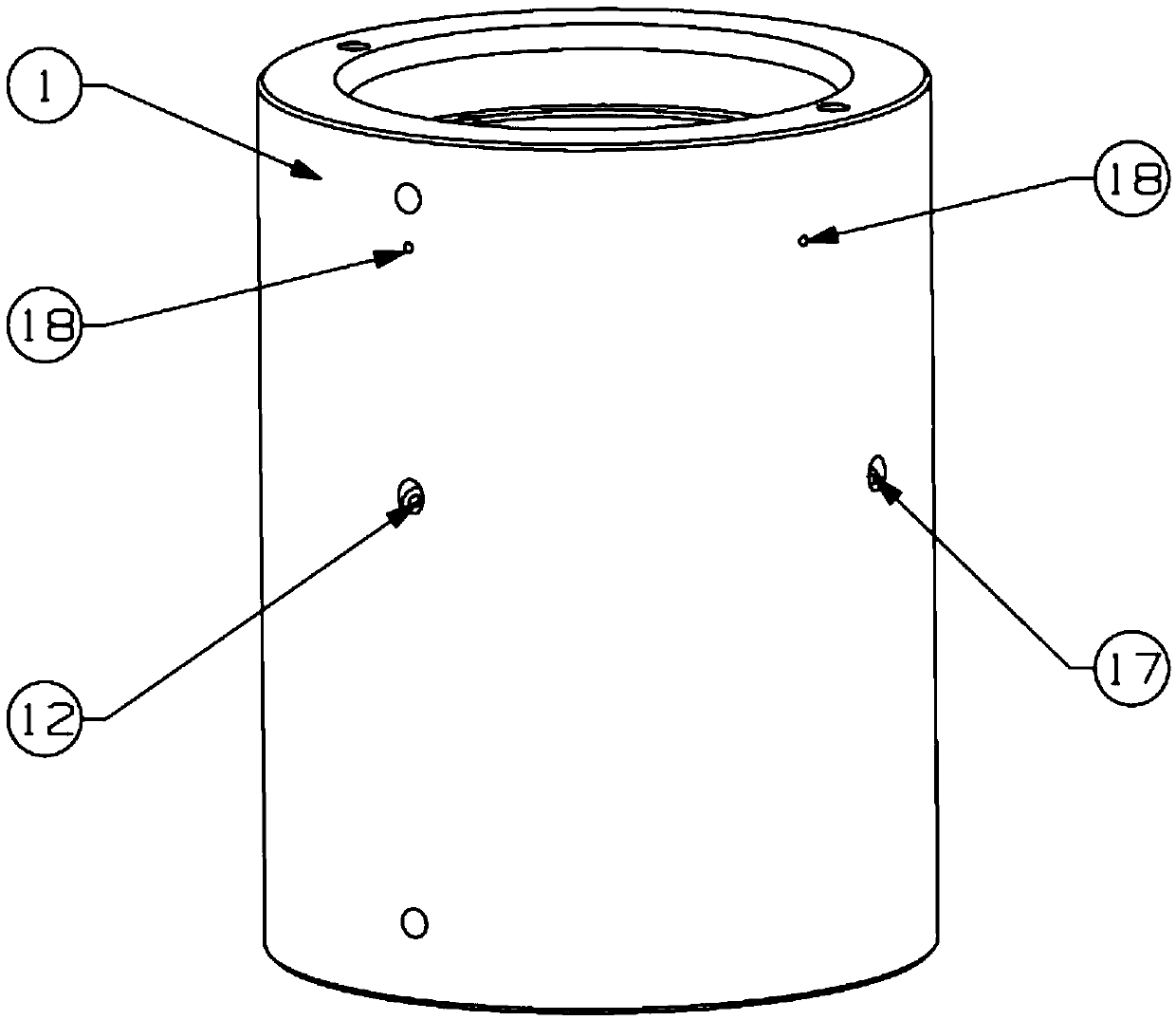

[0034] Such as figure 1 with figure 2 As shown, a kind of underwater wellhead head annulus sealing ground test device that can be loaded and pressurized simultaneously, comprises simulated high-pressure wellhead head 1, simulated casing hanger 9 (simulated high-pressure wellhead head 1 The lower part of the inner cavity is equipped with inclined support steps, which match with the simulated casing hanger 9 inclined support steps to support the simulated casing hanger 9, and the inner wall profile of the simulated high-pressure wellhead head 1 is completely consistent with the standard high-pressure wellhead head product), stuck in the simulated The metal seal assembly in the annulus of the high-pressure wellhead head 1 and the simulated casing hanger 9 (the metal seal assembly includes a metal seal ring 7 that cooperates with each other, a seal drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com