A Parallel Calculation Method of Dynamic Mesh in Lubrication Flow Area of Rotor-sliding Bearing System

A sliding bearing and parallel computing technology, which is applied in the field of computational fluid dynamics simulation, can solve the problems of non-existence, data export errors, and inability to obtain accurate shaft journal center coordinates, so as to ensure calculation accuracy, overcome low simulation efficiency, and improve The effect of computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

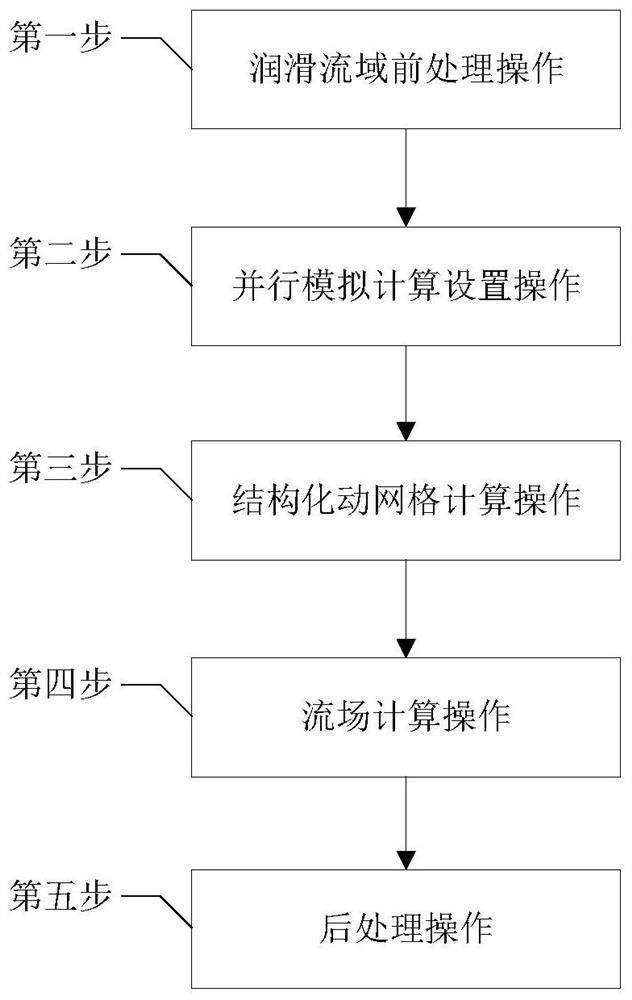

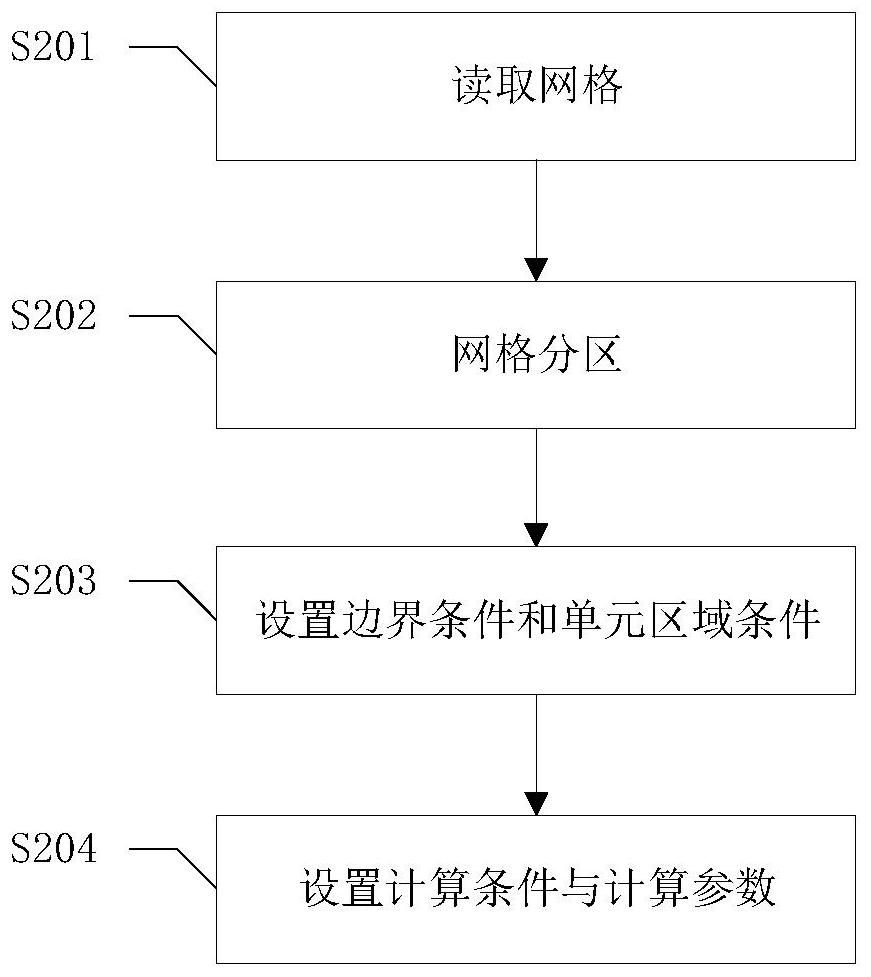

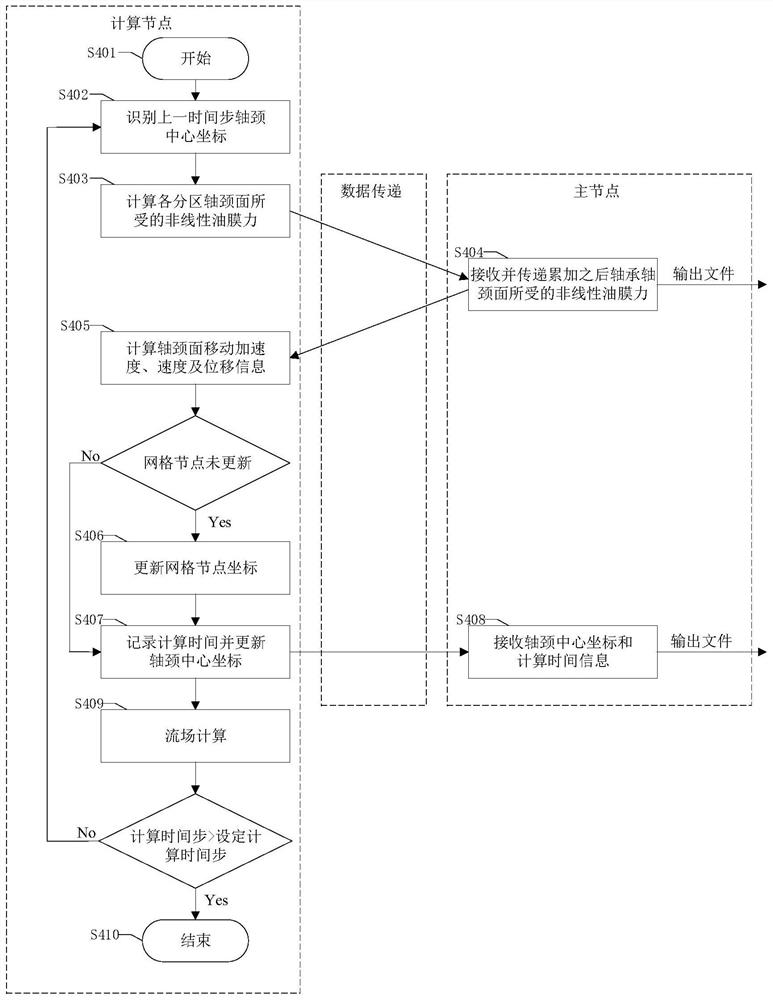

Method used

Image

Examples

Embodiment 1

[0106] Embodiment 1: Parallel calculation of a sliding bearing with two oil wedge oil inlet ports arranged at both ends along the radial direction.

[0107] 1.1 Establish the research object as the gap lubrication area and the lubrication path flow channel of the fixed pad cylindrical sliding bearing system with two oil inlets equipped with two oil wedges along the radial direction, which is defined as the lubrication flow area, and the sliding bearing and The rotor gap flow domain is defined as a structured dynamic grid area, referred to as the dynamic grid area, and the oil inlet hole and lubrication channel flow domain of the oil wedge in the system is defined as a mixed grid area.

[0108] 1.2 Establish the discretized mesh model of the rotor-sliding bearing lubrication water domain. The water domain in the gap between the bearing and the journal is divided into structured hexahedral grids, and the water domain in the oil inlet hole and the oil wedge are divided into hybrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com