Extreme pressure resistance testing device for bubble cap

A pressure test and blister technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problem of not being able to truly detect the ultimate pressure resistance quality of batches of blisters, and the inability to test the ultimate pressure resistance of blisters Capability and other issues, to achieve the effect of simple test, low production cost, and reduce instantaneous pressure shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

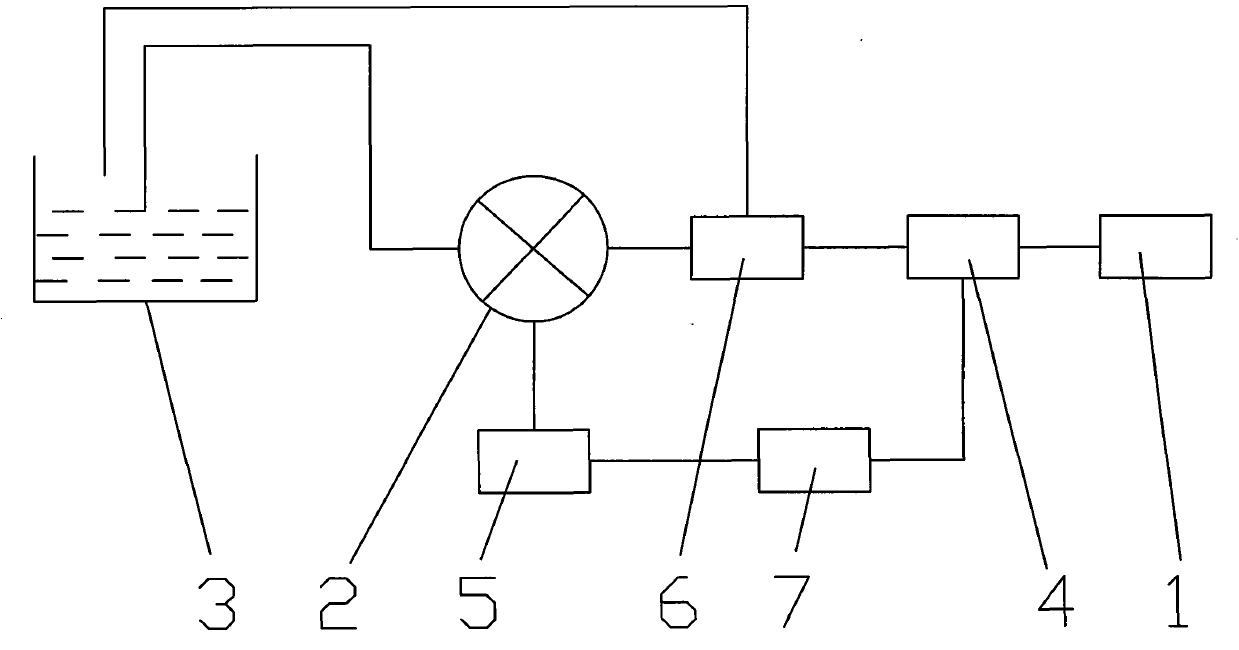

[0015] refer to figure 1 , a bulb ultimate pressure test device with low cost and high safety factor provided by the present invention, which includes a delivery pump 2 for sending the pressure measuring medium into the bulb 1, a pump for testing the pressure value in the bulb 1 The sensor 4 and the control valve 5 used to control the delivery speed of the delivery pump 2, the medium input end of the delivery pump 2 is connected to the pressure measuring medium source 3 through a pipeline, the medium output end of the delivery pump 2 is connected to the bulb 1 through a pipeline, and the control valve 5 The control terminal is connected with the sensor 4 , and the control valve 5 adjusts the delivery speed of the delivery pump 2 according to the signal fed back from the sensor 4 to the controller 7 . The controller 7 can be a controller such as PLC. Preferably, a buffer container 6 is connected to the medium output end of the delivery pump 2, and the buffer container 6 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com